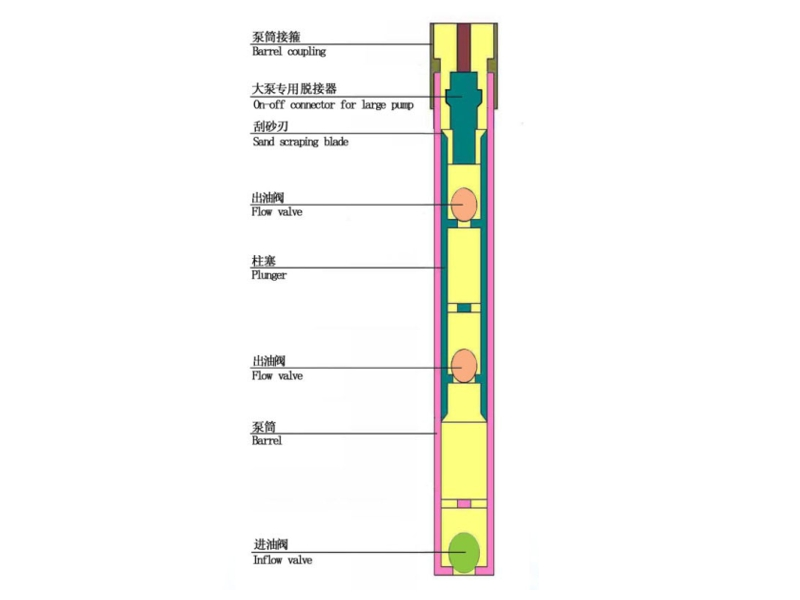

1. The API rod pump can be lowered into the tubing as a whole along with the sucker rod. When checking the API sucker rod pump, there is no need to lift and lower the tubing, which greatly shortens the operation time. Since the operation time is shortened and the number of times the tubing is unfastened is reduced, the service life of the tubing is extended. 2. The sealing support joint of the API rod pump is universal with the tubing. When changing different pump diameters, there is no need to adjust the tubing string of the API rod pump, which reduces maintenance costs. 3. The API rod pump produced by our company has a wide range of applications, suitable for thin oil wells, heavy oil wells, high condensate oil wells, steam drive wells, deep wells, sand-containing wells, gas-containing wells, etc. The API rod pump solves the current problems of sand production in heavy oil wells.

EmailMore

1. API tubing rod pumps adopt an integrated thick barrel design, which can achieve precise matching of the plunger after precision grinding, and API tubing rod pumps adopt a large inner diameter design to increase the fluid displacement of each stroke. 2. API tubing rod pumps are designed with heavy-duty structure to withstand high loads, corrosion and extreme wear. 3. All wearing parts of API tubing rod pumps adopt modular design. On-site maintenance and replacement do not require large-scale lifting. API tubing pump can be directly disassembled and assembled at the wellhead manually. The interchangeability between API tubing rod pump parts is strong, and API tubing pump are suitable for various specifications of tubing and sucker rod systems.

EmailMore

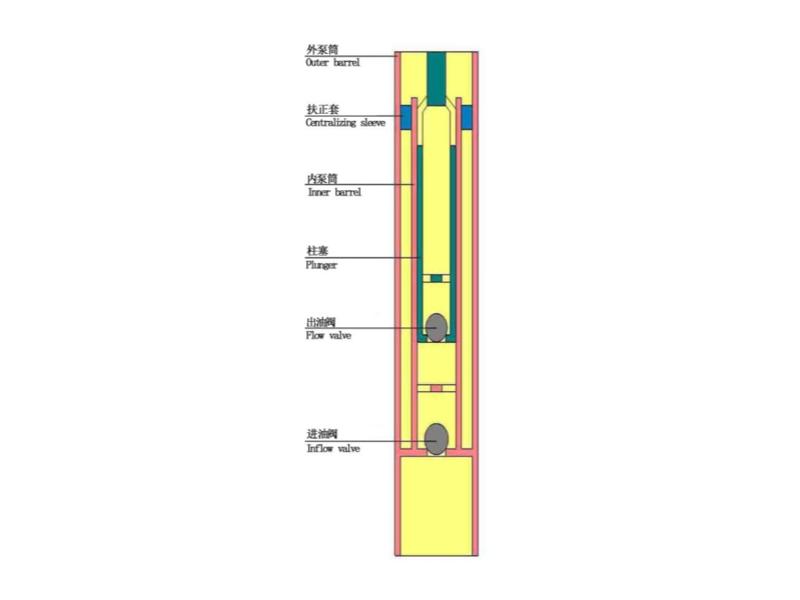

1. The inner wall of the long plunger sand control pump is chrome-plated (thickness 0.1-0.15mm), resistant to H₂S and CO₂ corrosion, and suitable for harsh environments with mineralization ≥10,000mg/L. 2. The long plunger sand control pump uses API standard threaded connections (such as 2 7/8 TBG), and plunger replacement can be completed without special tools. 3. The key components of the long plunger sand control pump are replaceable, such as the pump barrel, plunger, and valve group, which can be replaced independently to avoid overall scrapping and reduce maintenance costs by 40%.

EmailMore

1. Thin oil well sucker oil pump adopts modular design. The core components such as pump barrel, plunger, valve and so on adopt standardized and independent module design, which is convenient for disassembly and replacement. 2. All parts of Thin oil well sucker oil pump can be replaced by conventional oilfield tools without special equipment. 3. Thin oil well sucker oil pump is suitable for low pressure, low liquid level and low liquid production wells, solving the problems of difficult start-up and unstable oil pumping of traditional pumps.

EmailMore

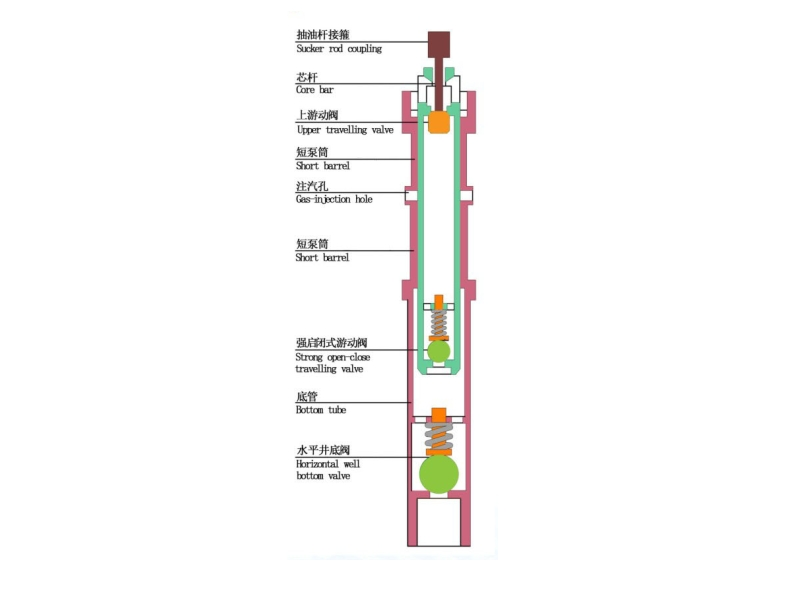

1. Our gas locking prevention oil well pump adopts a mechanical open-and-close oil inlet valve structure. When the gas enters the cavity of the gas locking prevention oil well pump, the pump valve automatically opens and closes by the reciprocating motion of the pump rod, effectively forcing the exhaust and stabilizing the fluid flow. 2. The inlet valve of the gas locking prevention oil well pump is made of high-strength corrosion-resistant alloy material. The gas locking prevention oil well pump avoids leakage or malfunction due to material fatigue. 3. The inlet valve of the gas locking prevention oil well pump adopts a streamlined guide channel design to make the fluid flow path smooth and continuous, reduce turbulence and resistance, and reduce the probability of release of dissolved gas in crude oil.

EmailMore

1. When the sucker rod is lifted 200mm, the plunger of the rod pump for steam injection thermal recovery is lifted synchronously through the mechanical linkage device to connect the steam injection hole of the sealing tube with the oil pipe. 2. The channel of the rod pump for steam injection thermal recovery adopts a high-temperature resistant alloy (Inconel 625) bushing, which can withstand continuous steam scouring at 350℃. In the field test of Liaohe Oilfield, the steam dryness retention rate is ≥85%. 3. When the plunger falls back, the cone surface (tolerance ±0.01mm) of the rod pump for steam injection thermal recovery forms a metal seal with the pump barrel, and the sealing pressure reaches 15MPa.

EmailMore

Reliable Rod Type Drainer (Drop Bar Type) for sucker rod pumps. High-precision shear pins ensure accurate drainage. Reduce oilwell workover costs and environmental risks. Custom sizes available.

EmailMore

High-quality lifting oil drain for oil well pumps. Designed to prevent fluid loss during tubing pull-out. API certified manufacturer. Contact Dongsheng for custom specifications.

EmailMore

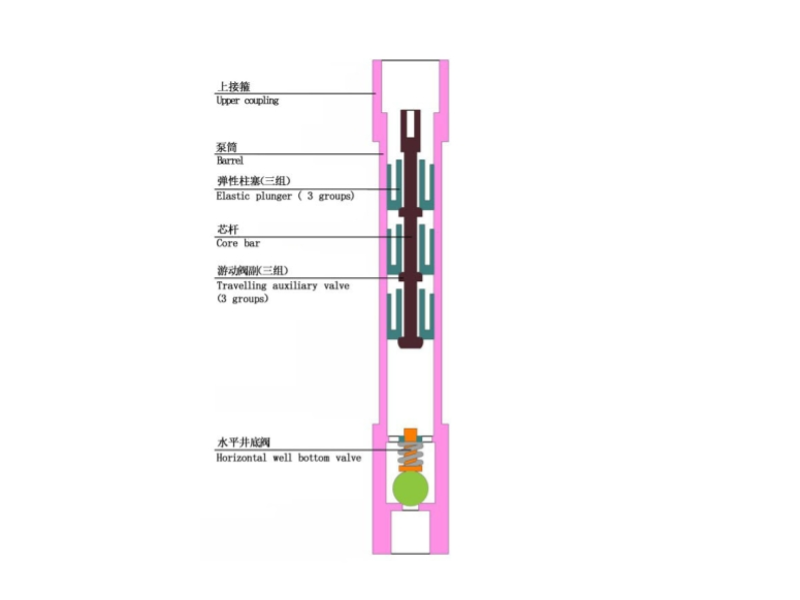

1. Optimized Sand Management: Featuring a unique 45° spiral guide groove design between sealing stages, our elastic seal pump increases sand discharge efficiency by 60%, significantly reducing pump plugging in high-sand environments. 2. Elastic seal sucker oil well pump uses all-metal structural parts with special heat treatment (QT800-10 material), which can maintain sealing performance under steam drive (350°C). 3. Elastic seal sucker oil well pump has built-in tungsten carbide guide sleeve (hardness HRA92), which is suitable for horizontal wells with well inclination angle ≤90°.

EmailMore

1. The bottom of the plunger of the thermal recovery sucker rod pump is inlaid with a diamond composite (PDC) scraping ring, and the inner wall of the pump barrel of the thermal recovery sucker rod pump is laser engraved with micron-level flow-guiding lines (Ra 0.8μm) to form a vortex effect to prevent sand deposition. 2. The plunger of the thermal recovery sucker rod pump is made of Inconel 718 alloy (temperature resistance 650℃),the seal of the thermal recovery sucker rod pump is a graphite-metal composite material. 3. The thermal recovery sucker rod pump adopts a floating valve seat design, which automatically compensates for the thermal deformation of ±3mm.

EmailMore