12-05/2025

Global oil markets are entering 2025 with steady momentum. Upstream spending is rising, well intervention activity is increasing, and multiple international agencies confirm that the investment cycle that began in 2023–2024 is far from over. Although the pace of growth has moderated, the overall direction remains positive. Oil demand stayed slightly above expectations in 2024, and most global forecasts point to moderate, stable consumption through 2025. As a result, major producers are maintaining high operating levels across their onshore assets, while several regions are preparing additional drilling programs, workover campaigns, and well-restoration projects.

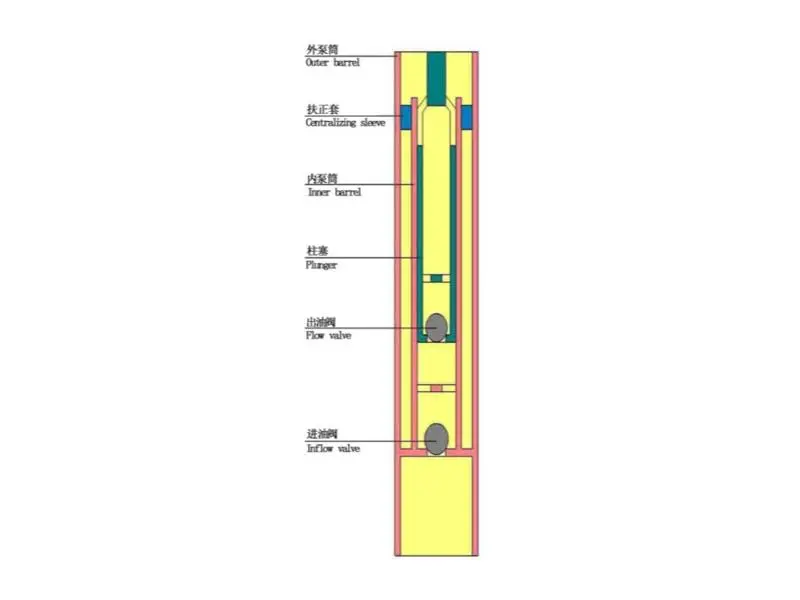

For procurement teams, these developments matter. They shape supply-chain availability, influence technical decisions, and affect the timing and volume of each oil rod pump order. The oil rod pump remains one of the most widely deployed artificial-lift systems in mature and developing fields, which means even modest increases in well activity can create noticeable pressure on equipment supply.