Dongsheng's Rod Type Drainer is a high-reliability tool that can effectively drain fluid from tubing string before pulling the pump during workover operation. The Rod Type Drainer, unlike the lifting type, is triggered by dropping a weighted bar (Drop Bar) or by the downward motion of the sucker rod string to cut the internal pins.

This is a must-have tool when it comes to keeping the rig floor clean and safe, lowering the chances of environmental contamination drastically, and increasing the overall efficiency of oilwell maintenance.

High Precision Activation: Equipped with calibrated shear pins that guarantee the valve to be opened only under the specified impact or pressure, thus production drainage will not be accidental.

Enhanced Safety: This method completely eliminates the necessity of pulling "wet" tubing strings: lowering the string weight and preventing the occurrence of oil spillage on the workover site.

Robust Construction: The tool is fabricated from top quality alloy steel (42CrMo/35CrMo) with heat treatment allowing it to be very strong and at the same time resistant to corrosion in downhole environments.

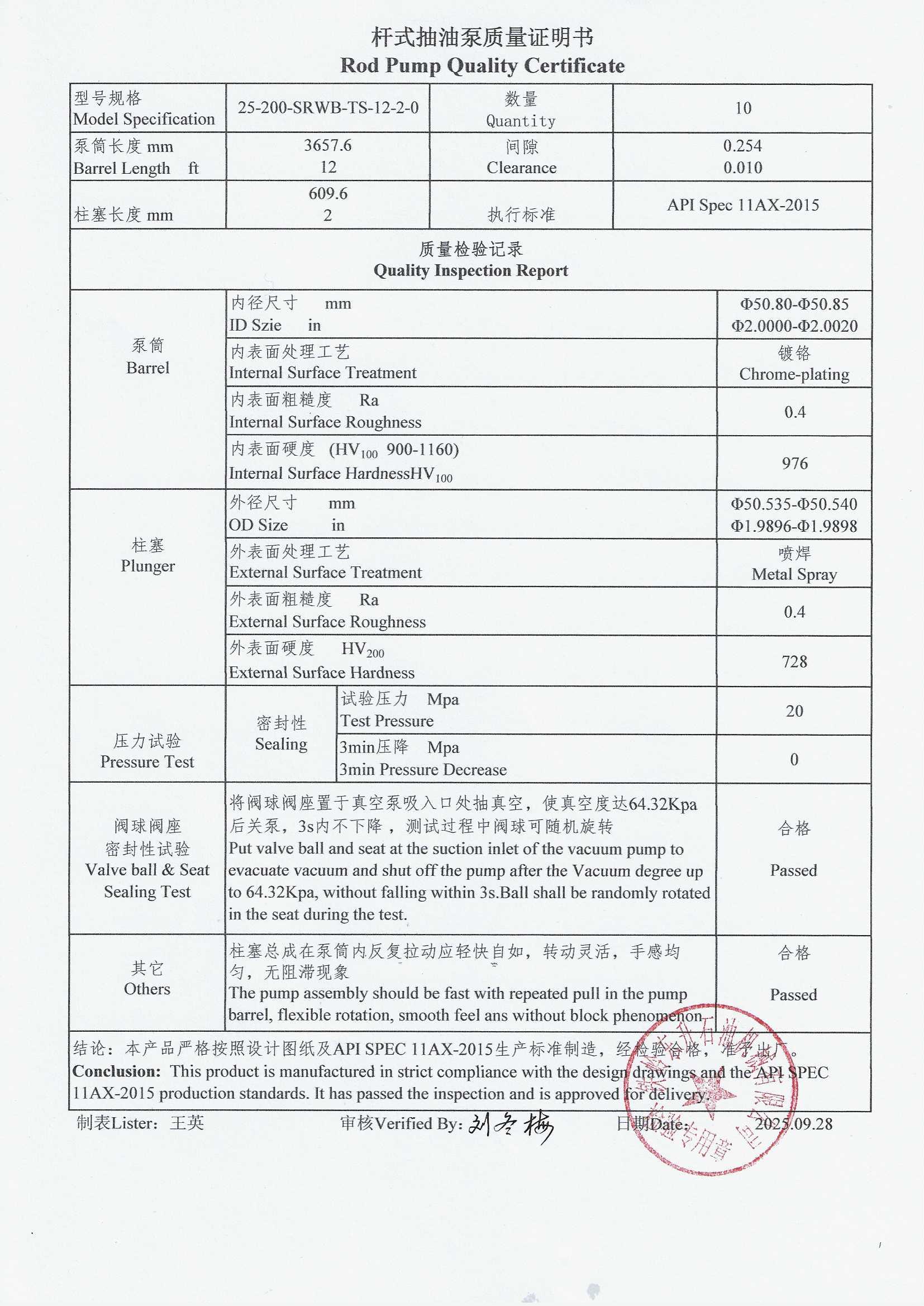

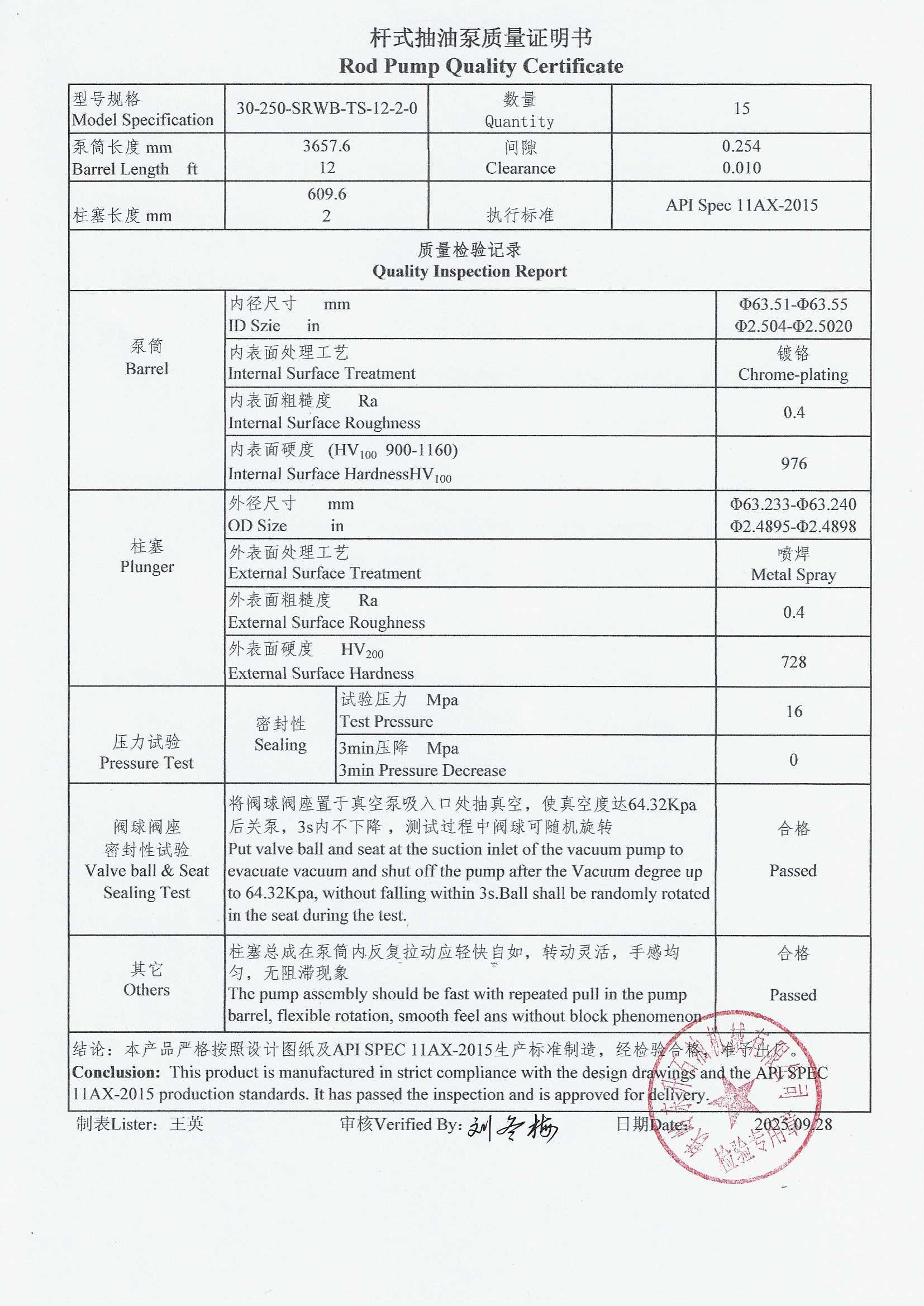

Universal Compatibility: It is a fully API 11AX compliant product, therefore, it is compatible with all standard sucker rod pump systems as well as tubing sizes.

Cost-Effective: An uncomplicated design with bare minimum movable parts, thus resulting in less maintenance cost and higher reuse rate.

| Parameter | Details |

| Material Grade | AISI 4140 / 42CrMo / Stainless Steel (Customizable) |

| Available Sizes | 2-3/8", 2-7/8", 3-1/2" |

| Standard | API 11AX / API 5CT |

| Connection | EUE / NUE (Tubing Threads) |

| Seal Material | Nitrile (NBR) / Viton (FKM) for high temperature |

| Application | Sucker Rod Pump Systems, Artificial Lift |

1. Normal Production: Drainage ports are blocked by a sliding sleeve which is held by the use of very accurately made shear pins.

2. Activation: In case of a workover, a weighted bar (drop bar) is thrown down from the surface or downward force is applied using the rod string.

3. Drainage: The force cuts the pins and thus the sliding of the sleeve down exposing the drainage ports. The fluid is in this way discharged from the tubing into the casing annulus.

Q1: How do I choose between a Rod Type Drainer and a Lifting Type Drainer?

A: The Rod Type Drainer is suited for wells in which you want the activation to be done by drop-bar or rod movement instead of pulling tension on the tubing. You will find its usage in the wells where the tubing string tends to get stuck or where precise mechanical impact is preferred over the hydraulic/tension methods.

Q2: What materials are available for high-corrosion wells?

A: For wells that have a very high concentration of H2S or CO2, we offer NACE MR0175 compliant materials and special coatings (e.g. Chrome plating or Ni-P plating) in order to prolong the life of the tool.

Q3: Can the shear pins be customized for specific depths?

A: Of course. Dongsheng has a variety of shear pins with different degrees of hardness. We can change the shearing force that is to be produced depending on your well depth, fluid density, and operational requirements to make sure that the activation is 100% reliable.

Q4: Is the installation process complicated?

A: It is quite simple to install since it goes into the tubing string right above the pump. You will be given an installation manual that is very thorough and with the help of technical support, your team will be able to do it quickly and in a safe manner.

Certified Excellence: We are an API 11AX and ISO 9001 certified manufacturer focusing on downhole pump accessories since 2000.

Global Reach: We have been providing our services in the oilfield sector to companies in the USA, Canada, Kazakhstan, and the Middle East.

Strict Quality Control: We have 100% material traceability, and pressure testing is done on each Rod Type Drainer unit.

Production Capacity: We have installed advanced CNC machining centers and professional testing labs to meet ±0.01mm precision requirements.