11-14/2025

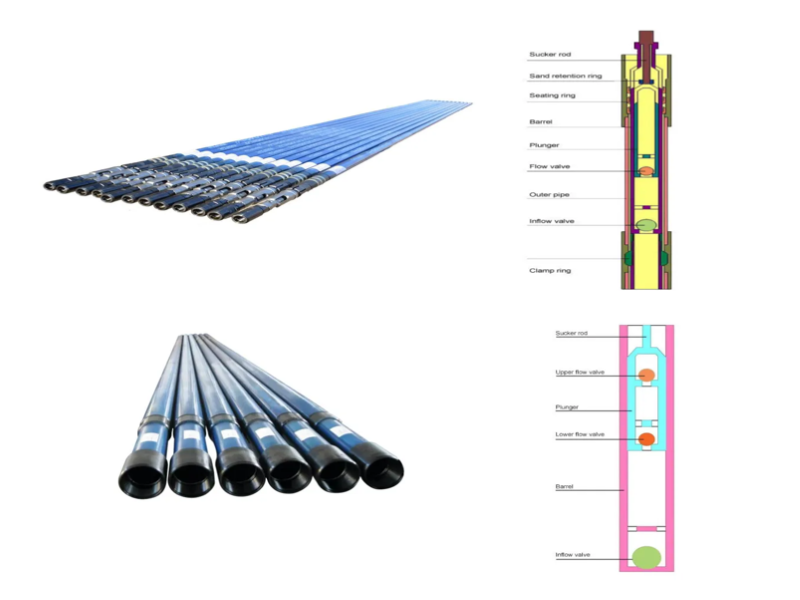

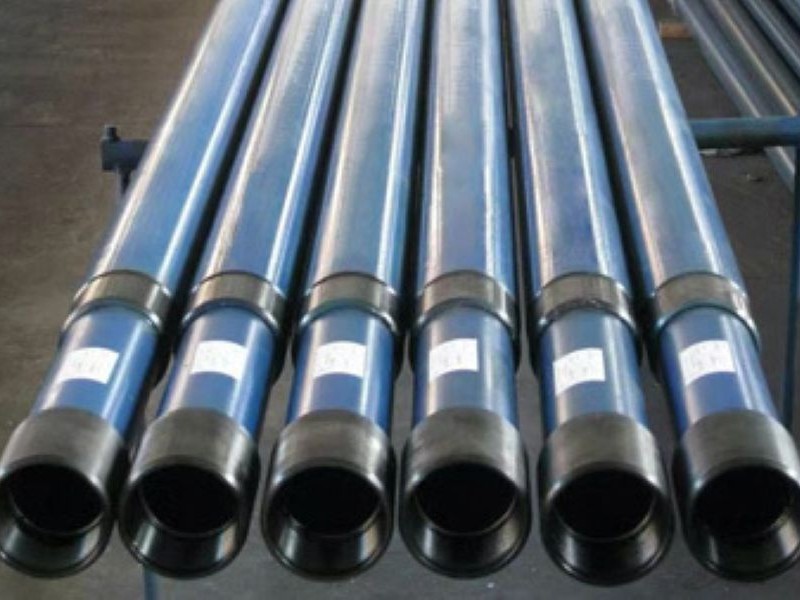

Recently, a delegation from SLB Company visited our company for technical exchanges and on-site inspections. Our company has long been deeply involved in the oilfield services sector, primarily engaged in the research, development, production, and technical services of sucker rod pumps, special sucker rod pumps, and related accessories. This visit was an important step for both parties to further strengthen understanding and explore cooperation opportunities.