Introduction of long plunger sand control pump:

Our company's long plunger sand control pump is specially developed for oil wells with high sand content and high mineralization. Through the lateral oil inlet structure, it solves the pain points of traditional oil pumps that are easy to get stuck and wear quickly. Long plunger anti-gas lock and anti-sand downhole pump covers 32-70mm pump diameter and stroke range of 3-6 meters, meeting the well conditions with daily liquid production of 5-200m³. The pump constant (K value) of the long plunger anti-gas lock and anti-sand downhole pump is accurately calibrated and can be directly connected to the oilfield SCADA system to realize real-time monitoring of displacement.

Advantages of sand control oil well pump with long plunger:

1. Sand control oil well pump with long plunger adopts classic sand prevention design, short pump barrel + long plunger structure. By adjusting the length ratio of pump barrel and plunger, the probability of sand accumulation between moving parts is reduced, and the risk of sand jam is reduced from the root.

2.Sand control oil well pump with long plunger adopts sinking sand and lateral oil inlet structure. Sand naturally settles to the isolation area at the bottom of the pump barrel to avoid entering the plunger friction pair. The lateral oil inlet design reduces the direct erosion of core components by crude oil carrying sand and prolongs the service life.

3. Sand control oil well pump with long plunger has triple sand prevention protection, and the failure rate is reduced by 60%. The plunger surface adopts laser cladding carbide layer (hardness HRC60+), which can effectively resist wear even if a trace of sand enters.

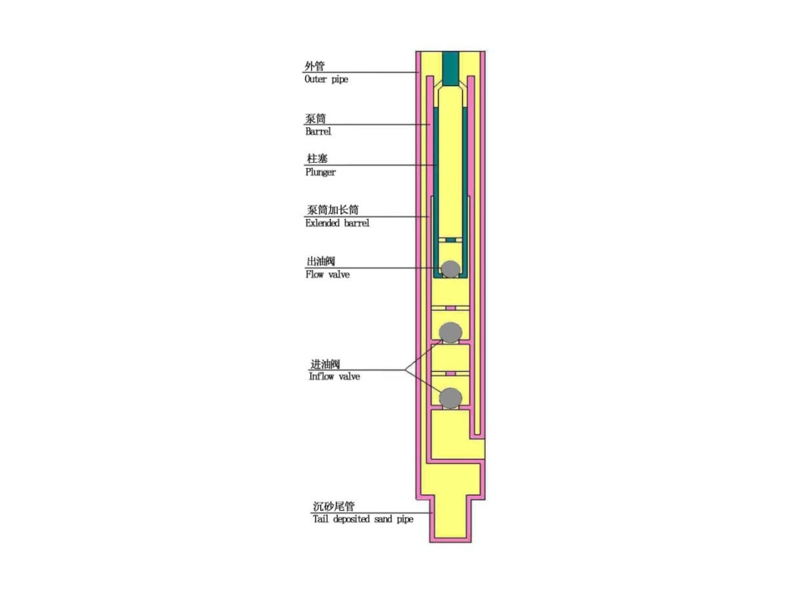

Structural diagram of long plunger sand control pump:

The core structure of long plunger anti-sand sucker rod pump includes:

Outer pipe: provides overall structural support and protection, and is the main pressure-bearing component outside the oil pump.

Barrel: As the working chamber for the reciprocating motion of the plunger, its processing accuracy directly determines the pump efficiency and sealing performance.

Plunger: forms a sealing pair with the pump barrel, and performs reciprocating linear motion during the oil pumping process to realize the upward transportation of crude oil.

Extended barrel: increases the plunger stroke range, improves the single displacement and suction efficiency.

Flow valve: The liquid outlet valve is installed above the plunger and opens when the plunger is on the stroke.

Inflow valve: allows liquid to enter the pump barrel to prevent backflow.

Tail deposited sand pipe: used for slight sanding conditions in oil wells, set at the bottom of the pump body, used to deposit sand near the pump suction port to prevent impurities from entering the pump cavity and causing blockage or plunger jamming.

Technical parameters of API long plunger anti-sand sucker rod pump:

| Pump bore (mm) | Length of plunger (m) | Length of barrel (m) | Range of stroke (m) | Pump constant | Size of connecting sucker rod | Size of connecting tubing (in ) | Max outside diameter (mm ) |

| 32 | 4.5~7.4 | 1.5 | 3.0~6.0 | 1. 14 | CYG19 | 2 3/8TBG | 73 |

| 38 | 1.64 | CYG19 | 2 3/8 or 2 7/8TBG | 73/89 | |||

| 44 | 2. 23 | CYG19 | 2 7/8TBG | 89 | |||

| 50 | 3.69 | CYG19 | 2 7/8TBG | 89 | |||

| 57 | 5. 52 | CYG19 | 2 7/8 or 3 1/2 TBG | 100 | |||

| 73 | 7.70 | CYG22 | 3 1/2TBG | 114 |

Application of long plunger anti-gas lock and anti-sand downhole pump:

1. High sand content oil fields: such as alluvial geology of Bohai Bay and Shengli Oilfield.

2. High mineralization wells: Long plunger anti-sand sucker rod pump is suitable for saline water layers with total mineralization ≤50,000mg/L.

3. Heavy oil thermal recovery wells: API long plunger anti-sand sucker rod pump can withstand temperatures up to 150℃ and is used in conjunction with steam stimulation process.

About us:

Our company is located in Liaoning Province, China, covering an area of 10,000 to 30,000 square meters, with more than 100 employees and an annual production capacity of 5 million to 10 million US dollars. As a qualified supplier of enterprises such as CNPC and Sinopec, the company has passed the ISO9001 quality management system certification and obtained API 11AX international certification. The quality of API long plunger anti-sand sucker rod pump is strictly implemented in accordance with international standards.

We adhere to the "customer-centric" principle, continuously improve the performance and service quality of various products such as API long plunger anti-sand sucker rod pump, and are committed to providing reliable, efficient and economical products to the global oil drilling industry.