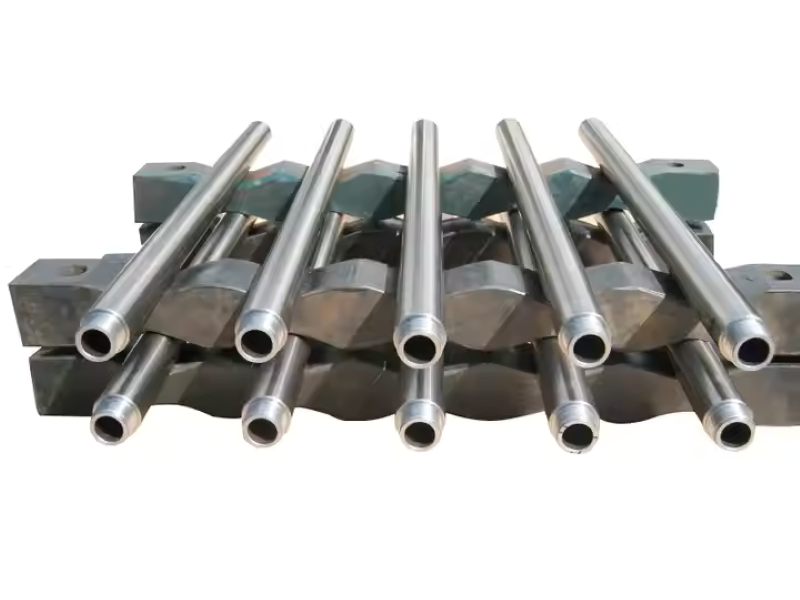

1. The spray welding layer of metal spray welding plunger is bonded to the base metal through metallurgical brazing, and the bonding strength can reach 200-300MPa, which exceeds the ordinary coating and can be used for a long time without peeling. 2. The metal spray welding plunger has high hardness, corrosion resistance and oxidation resistance, which is conducive to extending the service life of the plunger under various working conditions. 3. The metal spray welding plunger has good oxidation resistance and is suitable for the transportation of various high-temperature and corrosive media.

EmailMore

1. Metal spray welding long plunger is corrosion-resistant, wear-resistant and dimensionally stable. 2. Metal spray welding long plunger has passed API 11AX and ISO 9001 dual certification, and its quality is guaranteed. 3. Metal spray welding long plunger is packaged with shockproof and moisture-proof materials to adapt to different logistics methods such as long-distance sea, land or air transportation.

EmailMore

1. Specialty spray metal plunger can effectively reduce oil leakage and can withstand long-term friction. 2. Specialty spray metal plunger has passed API 11AX and ISO 9001 standard certification, and the quality of special plunger is guaranteed. 3. The wear resistance and corrosion resistance of specialty spray metal plunger make it efficient and stable in oil drilling and mining.

EmailMore