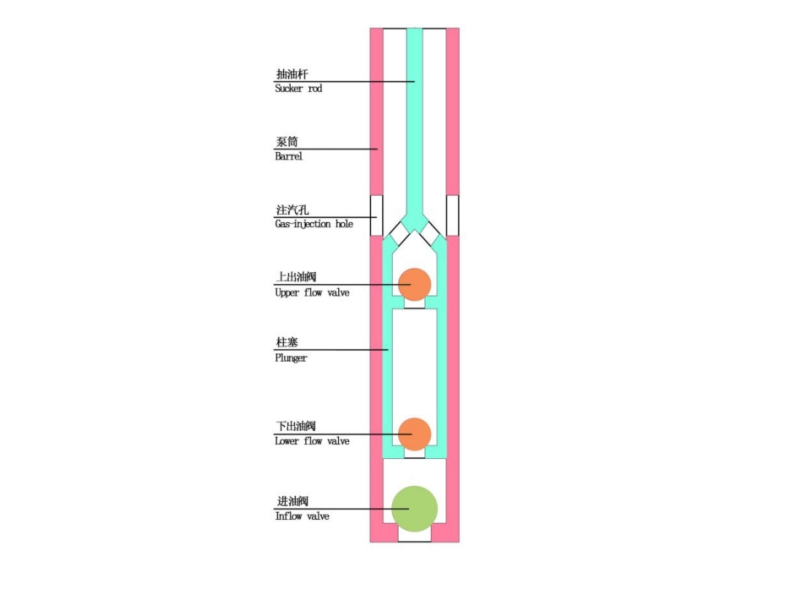

1.Large displacement tubing pump has dual working state switching function. Large displacement tubing pump can operate in two different working modes through the switch connector between the upper plunger and the lower plunger. 2.Due to this dual working state, the large displacement tubing pump can still maintain efficient operation under the condition of temperature and viscosity changes. When the wellhead temperature drops and the viscosity increases, the switch connector switches to the "open" position and continues to work efficiently. 3.When the large displacement tubing pump switch connector is in the "off" position, the displacement of the pump is the same as the size of the upper pump. When the large displacement tubing pump connector is switched to the "on" position, the displacement matches the oil inlet return pump, reducing energy loss.

EmailMore

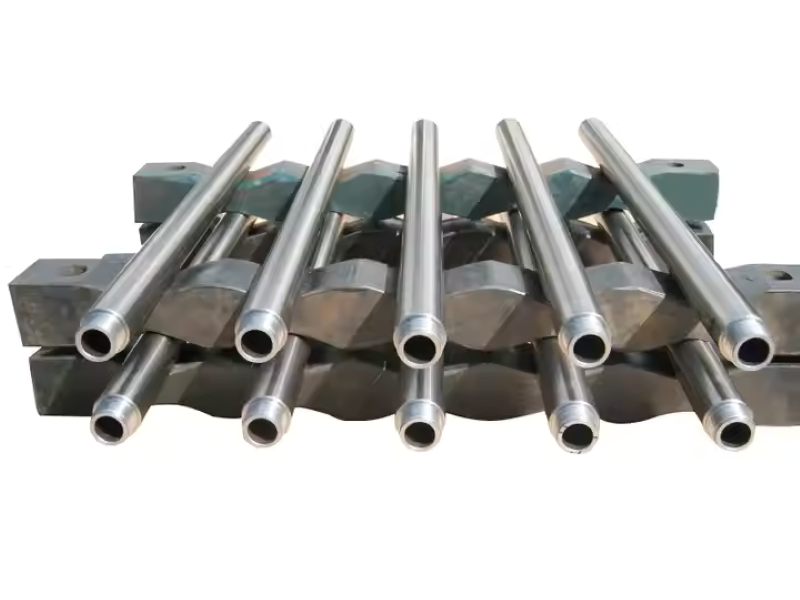

1. Chrome brass barrel for oil pump adopts double anti-corrosion structure of brass base and hard chrome plating, which is resistant to strong acid, strong alkali and seawater corrosion. The service life of chrome brass barrel for oil pump is more than 2 times that of ordinary stainless steel barrels for sucker rod pumps. 2. Chrome brass barrel for oil pump is hygienic and safe, perfectly matches the plunger, and effectively prevents medium leakage. 3. Chrome brass barrel for oil pump has passed ISO9001 and API11AX certification, and the whole process from raw materials to finished products is tested. The performance of each chrome brass barrel for oil pump is stable and reliable.

EmailMore

1. The surface of our sand scraping sucker rod well pump plunger is coated with high hardness and wear-resistant alloy (such as nickel-based alloy, tungsten carbide coating), and the inner wall of sand scraping sucker rod well pump is precisely polished to improve the hardness and smooth the surface, further reducing the adhesion and wear of sand particles. 2. The moving parts (plunger and pump barrel) of sand scraping sucker rod well pump are made of highly wear-resistant and corrosion-resistant materials, such as special alloy steel and stainless steel, and the surface of sand scraping sucker rod well pump is treated with high-frequency quenching or chemical plating. 3. In salt water and high H₂S environment, the pump barrel and plunger surface of sand scraping sucker rod well pump are treated with anti-corrosion composite coating, which effectively resists the corrosion of CO₂, H₂S and chloride ions in oil wells.

EmailMore

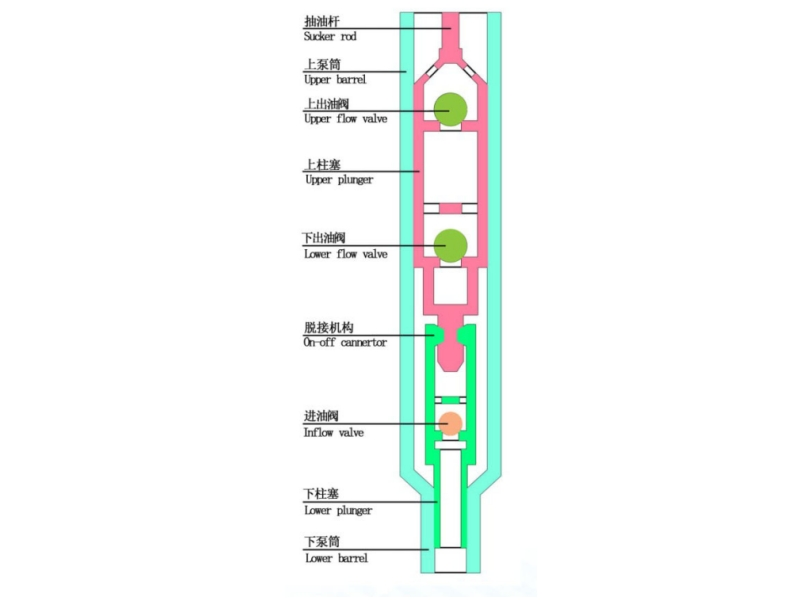

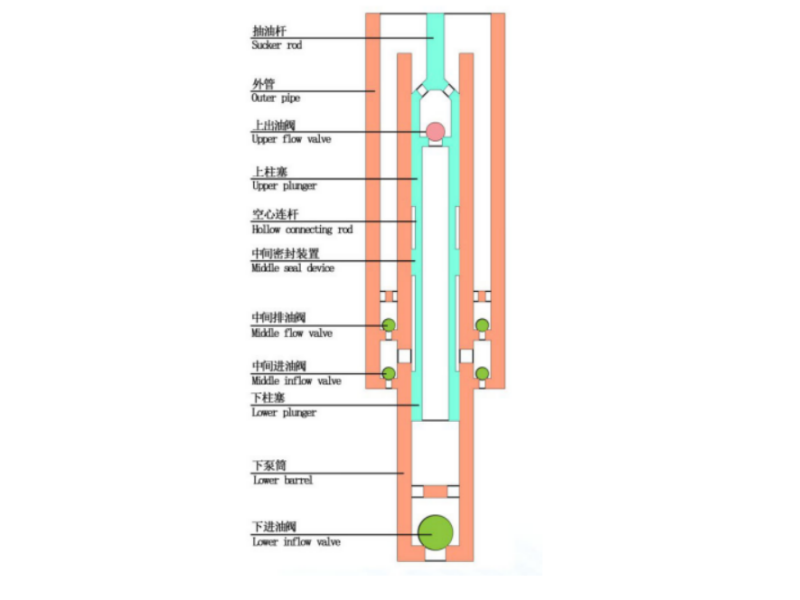

1. Our separate layer production oil well pump can be used to pump crude oil from multi-layer wells, which can greatly increase the single well production and crude oil recovery rate. 2. Our separate layer production oil well pump can exploit different oil layers separately, reduce inter-layer interference, and thus increase the overall production of the oil well. Our separate layer production oil well pump is particularly suitable for oil fields with uneven oil layer distribution or significant permeability differences. 3. Our separate layer production oil well pump has a simple pump string and convenient construction and operation.

EmailMore

1. The spray welding layer of metal spray welding plunger is bonded to the base metal through metallurgical brazing, and the bonding strength can reach 200-300MPa, which exceeds the ordinary coating and can be used for a long time without peeling. 2. The metal spray welding plunger has high hardness, corrosion resistance and oxidation resistance, which is conducive to extending the service life of the plunger under various working conditions. 3. The metal spray welding plunger has good oxidation resistance and is suitable for the transportation of various high-temperature and corrosive media.

EmailMore

1. Metal spray welding long plunger is corrosion-resistant, wear-resistant and dimensionally stable. 2. Metal spray welding long plunger has passed API 11AX and ISO 9001 dual certification, and its quality is guaranteed. 3. Metal spray welding long plunger is packaged with shockproof and moisture-proof materials to adapt to different logistics methods such as long-distance sea, land or air transportation.

EmailMore

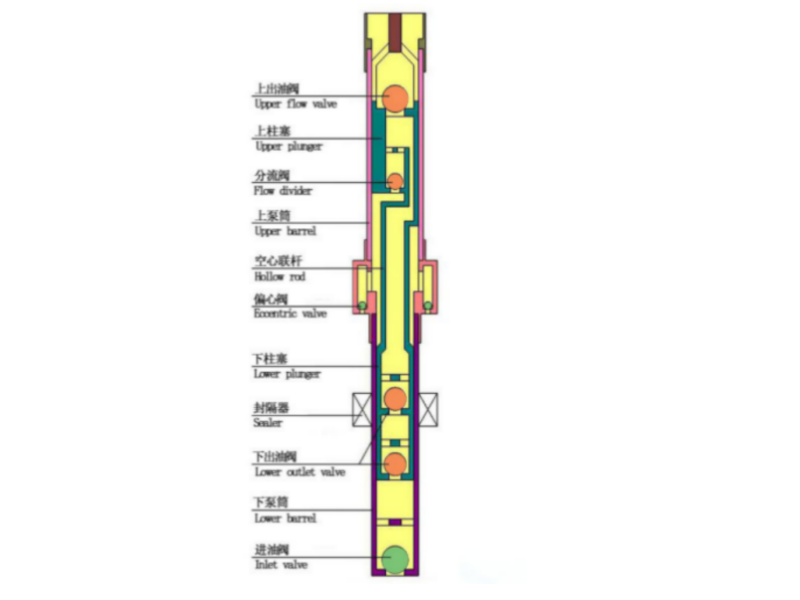

1.Three-acting tandem oil well pump is suitable for oil wells with sufficient liquid supply. 2.Three-acting tandem oil well pump can suck and discharge liquid during the up and down strokes. Three-acting tandem oil well pump has the characteristics of small pump diameter, large displacement, and deep pumping. 3.The special structure of three-acting tandem oil well pump enables three oil suction and three oil discharge actions to be completed in one reciprocating stroke, which can realize multi-layer oil wells.

EmailMore

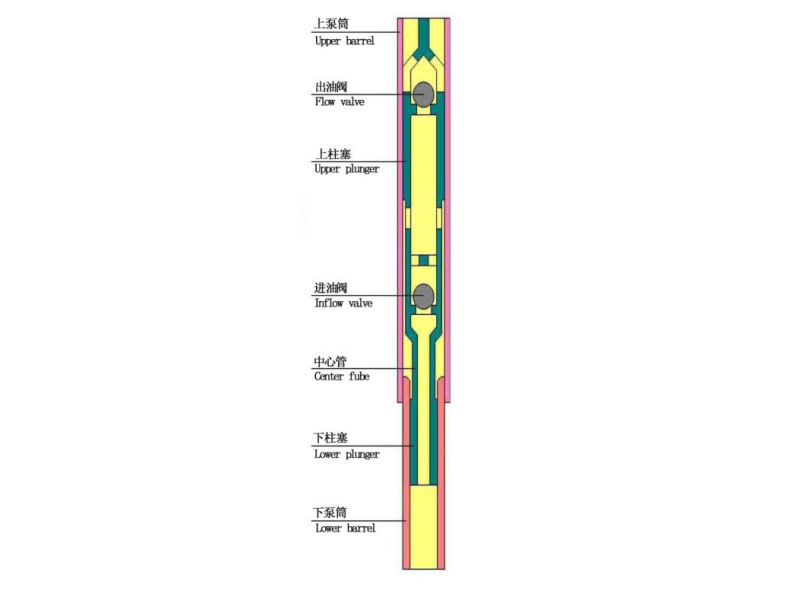

1. Separate production oil pump can be widely used in multi-level crude oil suction, which can greatly increase the single well production and recovery rate, reduce production costs, and have high comprehensive economic benefits. 2. Separate production oil pump is a downhole equipment used to extract oil from two formations simultaneously and separately, which is conducive to avoiding oil mixing and contamination. 3. We will take measures to prevent collision and falling during loading and unloading to avoid damage. During the transportation of Separate production oil pump, the support seal assembly will be protected with a protective cap or cotton cloth to prevent damage to the sealing surface.

EmailMore

1. Upward stroke: When the plunger of the heavy oil pump with hydraulic feedback moves upward, the upper liquid enters the lower chamber through a specially designed feedback channel to form hydraulic energy storage. 2. Downward stroke: The stored hydraulic energy is converted into auxiliary thrust (actually measured up to 2-5kN), and the heavy oil pump with hydraulic feedback can effectively overcome the resistance of heavy oil. 3. Pressure balance design: The heavy oil pump with hydraulic feedback uses our original two-way flow channel structure to balance the pressure inside and outside the pump in real time to avoid air lock and sand jam.

EmailMore

1. Sucker rod for high viscosity oil exploitation adopts 0.8m anti-stroke distance design + fluid mechanics optimization, which extends the equipment life by 50% and reduces the annual maintenance cost by 20,000 yuan. 2. Sucker rod for high viscosity oil exploitation has 4 pump diameters (32mm-57mm) to adapt to different well depths and oil products, reducing the comprehensive procurement cost by 25%. 3. Based on the Q=KSN formula, the stroke and stroke frequency are dynamically adjusted, and the theoretical displacement of sucker rod for high viscosity oil exploitation is up to 400m³/d.

EmailMore