Annulus thermal recovery pump oil well adopts large-caliber long-stroke pump barrel and plunger, which effectively increases the liquid production. A special disconnector for large pumps is used to complete the disconnection of the plunger and the sucker rod. The upper oil outlet valve and the lower part of the plunger are processed with sharp-angle scraping edges. During the reciprocating motion of the plunger, the annulus thermal recovery pump oil well continuously removes the scale and sand particles on the inner wall of the pump barrel, reducing and avoiding sand jams in the oil pump.

Annulus thermal recovery pump oil well is suitable for pumping heavy oil and super-heavy oil under special conditions such as high temperature and sand content, and heavy oil recovery sucker rod pump is successfully solves the problem of super-heavy oil extraction in China.

Utilizes Inconel 718 and specialized heat-treated alloys (QT800-10) to maintain high-precision sealing under extreme temperature cycles.

Eliminate the need for dual workovers. Our design allows high-dryness steam injection directly through the pump, saving up to 8 hours of rig time.

Featuring a unique Floating Valve Seat design that compensates for ±3.5mm of thermal deformation, preventing the "Plunger Stuck" issues common in heavy oil recovery.

Integrated with PDC (Polycrystalline Diamond) Scrapers to remove paraffin and scale buildup in real-time.

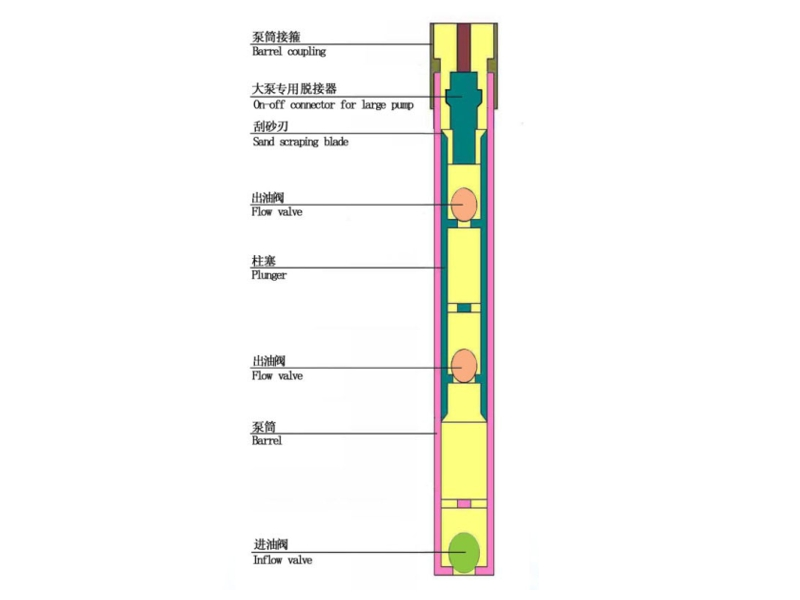

The core structure of steam thermal rod pump includes:

Barrel coupling: an important connection between the pump barrel and the sucker rod, usually a threaded connection structure.

On off connector for large pump: a disassembly connector suitable for large-size or deep-well oil pumps.

Sand scraping blade: installed near the plunger, used to remove sand and impurities in the inner wall of the pump barrel or the pump cavity.

Flow Valve: located above the plunger, opened when the plunger is on the upstroke and closed when the plunger is on the downstroke.

Piunger: a core moving part, usually sprayed with nickel-based alloy or hard chrome plating on the surface to improve wear resistance and corrosion resistance.

Flow valve: an auxiliary flow valve, an optional configuration, used to supplement and regulate liquid flow, suitable for multi-plunger structures or special working conditions that require segmented suction.

Barrel: the pump barrel not only bears the pressure of the liquid column, but also cooperates with the plunger to achieve sealed suction,

Inflow Valve: installed at the bottom of the pump barrel, opened when the plunger is on the downstroke and closed when the plunger is on the upstroke.

Pump bore of annulus thermal recovery pump oil well (mm) | Length of plunger (m) | Length of barrel (m) | Range of stroke (m) | Pump constant of steam thermal rod pump | Size of connecting sucker rod | Size of connecting tubing (in ) | Max outside diameter (mm ) |

108 | 1200 | 12 | 0~10 | 13.17 | CYG25 | 4 1/2 TBG | 124 |

120 | 16.45 | 136 | |||||

140 | 22.06 | 153 | |||||

| 160 | 28.49 | 176 |

Plunger: Spray-welded with Nickel-based Alloy (Boro-Silicon-Nickel). Hardness: HRC 58-62. Provides superior resistance to CO2/H2S corrosion.

Barrel: 316L Stainless Steel or 42CrMo with heavy-duty chrome plating (0.25mm thickness).

Valve Ball/Seat: High-density Tungsten Carbide (YG8/YN6) with HRA ≥ 90, ensuring zero-leakage sealing after thousands of thermal cycles.

Site Condition: Liaohe Oilfield, China’s largest heavy oil base. Well depth: 800-1200m. Crude oil viscosity: 250,000 mPa·s.

The Challenge: Traditional pumps required frequent pulling to switch from steam injection to production, leading to high operational costs and heat loss.

The Solution: Deployed Dongsheng Integrated Thermal Recovery Pumps.

The Result:

Steam injection dryness maintained at >85%.

Pump inspection cycle extended from 90 days to 240+ days.

Average single-well operation cost reduced by 15%.

Q1: How does the steam thermal rod pump deal with the high viscosity resistance of super heavy oil?

A: The plunger of the steam thermal rod pump has a built-in electric heating system (380V/15kW, viscosity reduction of 85%), and a chemical viscosity reducer injection interface (maximum injection pressure 35MPa).

Q2: What is the maximum pumping depth of the steam thermal rod pump?

A: The standard configuration of the steam thermal rod pump is suitable for wells ≤2800m deep, and the special reinforced version can reach 3500m (need to be used with HY-grade sucker rods).

Q3: What is the replacement cycle of the scraper blade of the thermal recovery sucker rod pump?

A: The life of the tungsten alloy scraper blade of the high temperature heavy rod pump is ≥ 2 years (calculated based on 1000 strokes/day). The replacement of the high temperature heavy rod pump only requires the removal of the plunger module.

Q4: Can this pump handle high-viscosity heavy oil?

A: Yes, the large-bore design reduces flow resistance, and when paired with our electric heating plunger, it can handle crude oil up to 5,000 mPa·s efficiently.

Q5: How does it handle thermal expansion at 300°C?

A: We use a proprietary floating-seal mechanism and thermal-grade alloys that have matched thermal expansion coefficients, ensuring the plunger moves freely without sticking.

We have successfully completed the shipment of a batch of oil well pumps and accessories to Canadian customers. This batch of equipment has been strictly produced, inspected and packaged in our workshop and is packed in reinforced wooden boxes that meet international transportation standards to ensure safety during long-distance transportation.

A Trusted Name in API 11AX Subsurface Pumps Since 2000

Tieling Dongsheng is a leading Chinese manufacturer specializing in the design, R&D, and production of high-performance sucker rod pumps and downhole tools. As a qualified Tier-1 supplier for CNPC, Sinopec, and Weatherford, we deliver engineering excellence to the global oil and gas industry.

Established: 2000 (25 years of industry expertise)

Manufacturing Base: 20,000+ m² state-of-the-art facility

Production Capacity: 20,000+ units of oil pumps per year

Workforce: 96 dedicated employees, including 20 senior engineers and technicians

Registered Capital: 56 Million RMB

Product Range: 100+ types of API-standard pumps, sand control pumps, and downhole accessories.

Certifications & Quality Assurance:

API Spec 11AX Certified: Licensed to use the official API monogram (Certificate for subsurface pumps and fittings).

ISO 9001 System: Certified Quality Management System covering the entire lifecycle from raw materials to finished products.

Full-Process Inspection: Integrated testing system for every batch, including ultrasonic flaw detection, precision gauging, and high-pressure performance testing.