1. API 11AX sucker rod pump is produced in strict accordance with the API SPEC 11AX specification, and the core components are authorized to use the API monogram. 2. The chrome-plated + plunger spray-welded nickel-based alloy process of the pump barrel given by API 11AX sucker rod pump has a corrosion resistance and wear-resistant life that is 1-3 times higher than that of ordinary pumps. 3. API 11AX sucker rod pump supports 28-108mm multi-pump diameter specifications, suitable for long-stroke deep pumping scenarios, and the pump efficiency is as high as 90% or more.

EmailMore

1.This API standard pump follows the API 11AX standard, is well sealed, wear-resistant, and can operate stably under complex operating conditions. 2.API standard pump has a precise structure and a sand-proof device, which extends the vulnerable life of API standard pump, reduces maintenance, and is cost-effective. 3.This API standard pump has many specifications and wide adaptability. It can be used in deep wells on land and sea, and we support customization on demand.

EmailMore

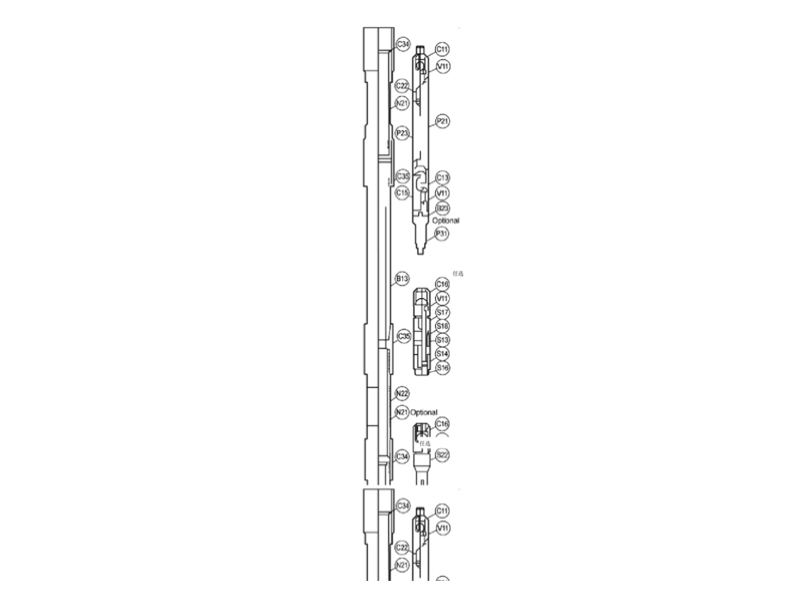

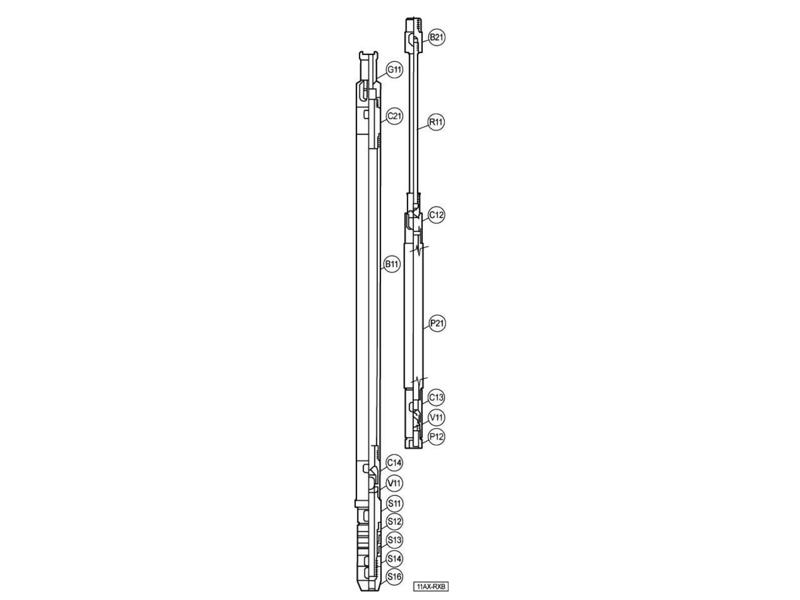

1. The thick walled pump barrel of RXB API insert pump(sucker rod pump) is designed to achieve efficient oil recovery at a depth of 10,000 feet and is suitable for medium deep to deep well conditions. 2. The fixed structure at the bottom of the RXB API insert pump eliminates the "breathing effect" of the pump barrel, and the operating stability of the RXB API insert pump is improved by more than 30%. 3. RXB API insert pump adopts all stainless steel overcurrent parts + wear resistant coating, and the service life of RXB insert rod pump is 1-3 times longer than that of traditional models.

EmailMore

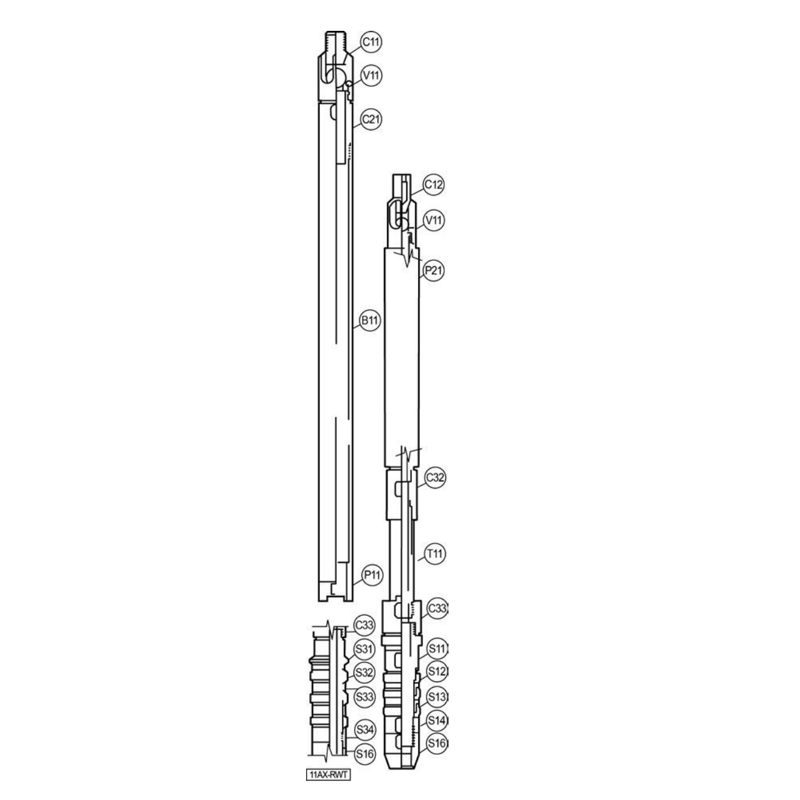

1. RWT API insert pumps can be used with the pumping rod column, which does not affect the oil pipe column, greatly saving operating time and cost. 2. This RWT API insert pumps is especially suitable for oil wells with small displacement pumping and deep pumping, which can meet a variety of working conditions. 3. The unique design of RWT API insert pumps reduces the risk of sand particles and other sedimentation stuck in the pump and ensures the stable operation of the pump.

EmailMore

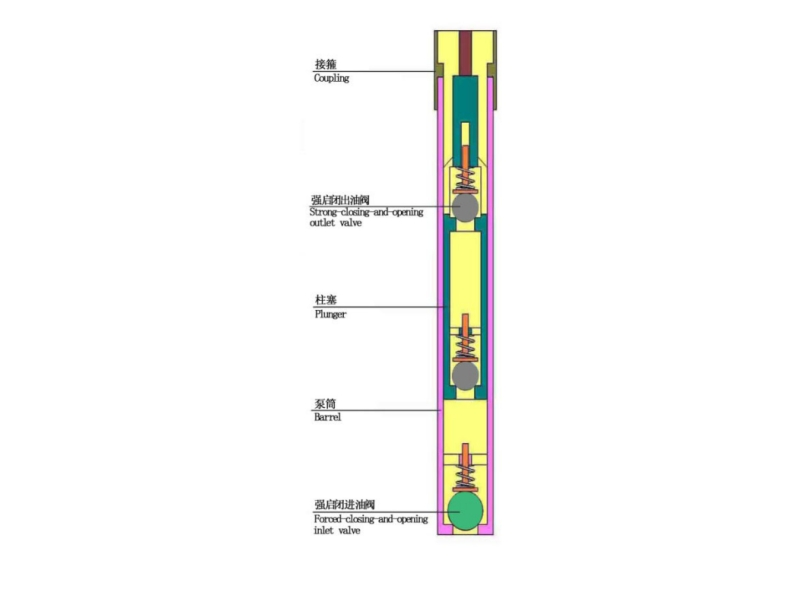

1. Our inclined well sucker rod pump adopts spring forced seat sealing technology, so our inclined well sucker rod pump solves the industry problem that the valve ball of traditional oil well pumps cannot return to its original position by gravity in inclined wells and horizontal wells. 2. Unlike ordinary oil well pumps that can only be used in vertical wells, our inclined well sucker rod pump can maintain stable operation at any angle of 0-90°. 3. The modular design of the inclined well sucker rod pump allows for quick replacement of pump diameter components (only 2 hours), and the same platform can adapt to different production capacity requirements of 32-95mm. 4. The special flow channel design of the inclined well sucker rod pump enables the viscosity adaptation range to reach 50-5000mPa·s.

EmailMore

1.RWB API insert pumps are suitable for many conditions such as low-sand wells and low-level wells, and API certification guarantees reliable quality. 2. RWB API insert pumps is designed with a high flow rate and a large inner diameter pump cylinder, which can increase the daily oil production of a single well.。 3. RWB API insert pumps has a fixed bottom + less connection structure, which effectively reduces failure and wear.

EmailMore

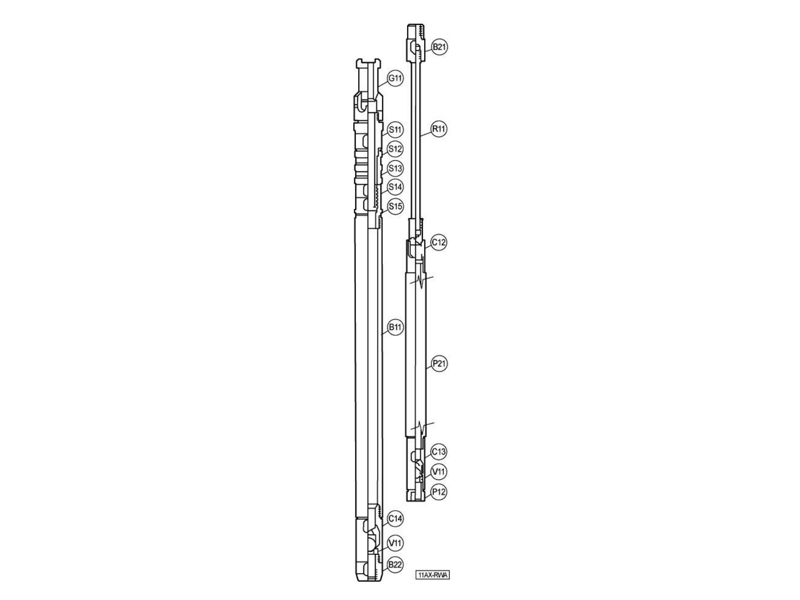

1. RWA insert rod pump's unique leather bowl support joint is fixed to the oil pipe. In case of failure, only the pumping rod and column can be brought out to bring out the whole pump, greatly simplifying maintenance operations. 2. The pump barrel of RWA insert rod pump adopts electroplating/nitriding treatment, the plunger adopts spraying/electroplating process, and the ball seat uses stainless steel/cemented carbide and other materials, which significantly improves the wear resistance and corrosion resistance of the core accessories. 3. The plunger assembly of RWA insert rod pump pumps oil with the movement of the sucker rod, forming an efficient working pair with the fixed pump cylinder, with a simple and reliable structure and high operating efficiency.

EmailMore

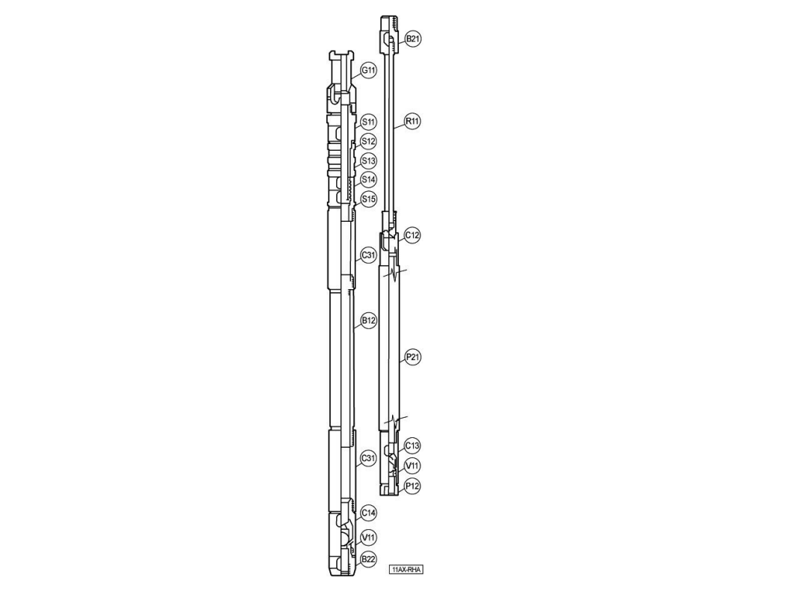

1. The RHA Insert rod pump features a thick-walled design, top anchoring, and is API-approved as a standard design. 2. The RHA Insert rod pump is suitable for medium-depth wells, sand-laden wells, and shut-in sand recovery sections. 3. Our RHA API insert pumps are reliable and durable, meeting international standards, and are available with custom materials and coatings.

EmailMore

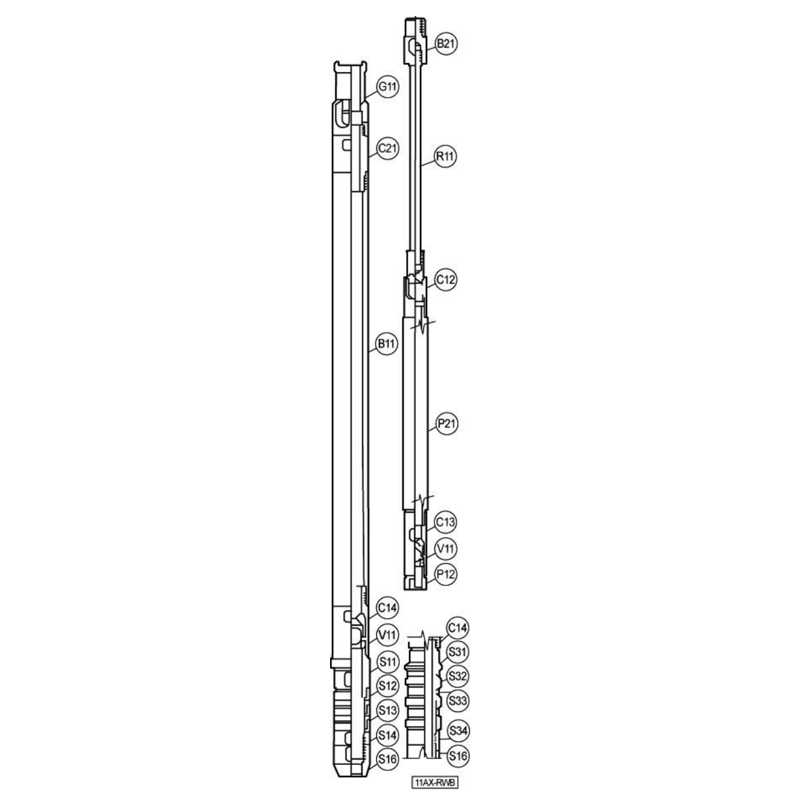

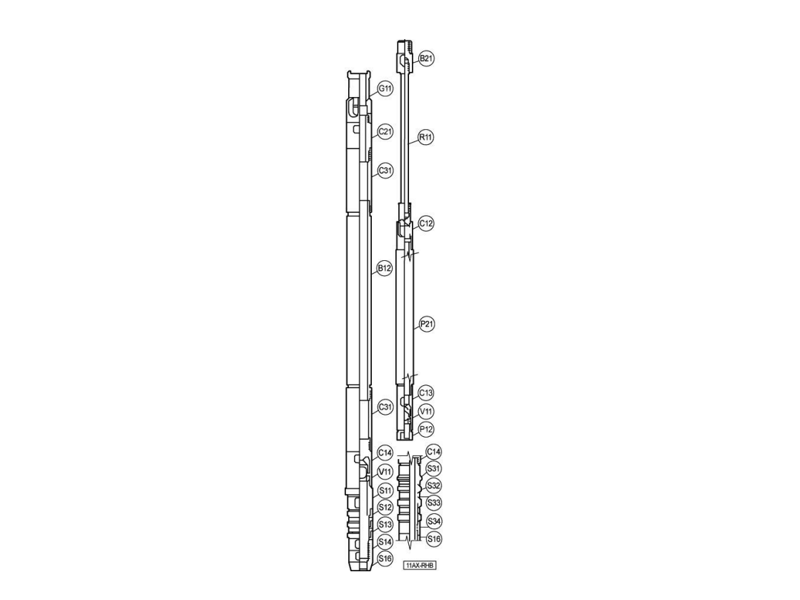

1. The RHB insert rod pump complies with API standards and is internationally accepted. The RHB is an API insert rod pump model with standardized parts, making it interchangeable with internationally accepted pumps. 2. Our RHB insert rod pumps cover a wide range of tubing sizes and pump diameters, allowing for flexible model selection based on well depth, fluid properties, and production requirements. 3. The RHB insert rod pump utilizes a thick-walled barrel, wear-resistant ball and seat, and a high-strength plunger to withstand wear from sand, gas, and corrosive fluids.

EmailMore

1. TH Tubing pump(sucker rod tubing pump) can be customized according to the special requirements of different occasions, and TH Piping Pump(sucker rod tubing pump) can be customized in batches with extended pump tubes. 2. The surface of the TH Tubing pump(sucker rod tubing pump) plunger is sprayed with nickel-based alloy, the inner wall of the pump barrel is hard chrome plated, and the valve cover and valve ball are made of high corrosion and wear-resistant materials. 3. TH Tubing Pump(sucker rod tubing pump) has excellent corrosion resistance and wear resistance, and its service life is 1 to 3 times higher than that of ordinary pumps.

EmailMore