Introduction to API tubing pump:

Our CYB-[d]TL(F1) series API tubing pump is designed to meet the needs of extraction in high-intensity wear and light corrosion environments. API tubing pump has a compact structure, stable performance, good load-bearing capacity and maintenance convenience, API tubing rod pumps is widely used in medium-deep wells, sand-containing wells and high-frequency operation wells.

In addition, we provide wear-resistant and corrosion-resistant versions. The key components of API tubing pump use high-performance composite coatings and special alloy materials. The service life of API tubing pump is 1-3 times longer than that of traditional models, API type tubing pump can significantly reduce the frequency of underground operations and comprehensive operating costs.

Advantages of API tubing pump:

1.The pump barrel of API tubing pump is made of high-strength steel with thickened wall thickness, which will not cause cracks, deformation and other problems under high-load and long-cycle operation. The surface hardness of the pump barrel of API tubing pump can reach HRC60 or above after carbonitriding treatment, which is much higher than that of ordinary carbon steel pump barrel.

2. The surface cladding technology of API sucker rod tubing pump evenly forms a 0.2mm+ nickel-based coating, so our API tubing pump has excellent self-lubrication, high temperature resistance and corrosion resistance. The wear rate between the plunger and the pump barrel is reduced. API type tubing pump is suitable for oil wells with complex liquid composition and frequent operation.

3. The static valve, dynamic valve ball and valve seat of API type tubing pump are made of high-strength stainless steel or ceramic material, and the corrosion resistance is improved by ≥300%. The full set of seals of API sucker rod tubing pump are controlled at ±0.01mm.

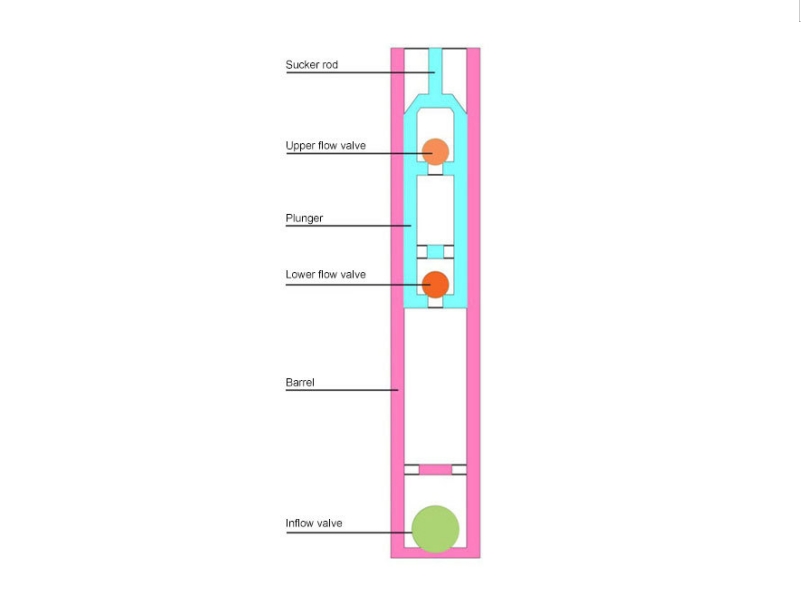

Structural diagram of API type tubing pump:

The core structure of API type tubing pump includes:

Sucker rod: driving mechanism, transmitting power.

Upper & Lower flow valve: controlling the one-way flow of fluid to ensure suction efficiency.

Plunger: back and forth movement to push the oil upward.

Barrel: made of high-strength material, it is the core pressure-bearing component of the pump.

Inflow valve: allows liquid to enter the pump barrel to prevent backflow.

The key components of API type tubing pump are all modular in design.

Technical parameters of API tubing rod pumps:

Pump bore of API tubing rod pumps (mm ) | Length of plunger (m) | Length of barrel (m) | Size of connecting tubing ( in ) | Pump constant of API tubing pump | Size of connecting sucker rod | Size of connecting tubing (in ) |

| 32 | 0.6~1.2 | 2.1~7.5 | 1.2~6.0 | 1.14 | CYG19 | 2 3/8 TBG |

| 38 | 1.64 | CYG19 | 2 3/8 TBG | |||

| 44 | 2.23 | CYG19 | 2 3/8 TBG | |||

| 57 | 3.69 | CYG19 | 2 3/8 TBG | |||

| 70 | 5. 52 | CYG22 | 3 TBG | |||

| 80 | 7.70 | CYG22 | 3 1/8 TBG | |||

| 93 | 10.26 | CYG25 | 4 TBG |

Application scenarios of API type tubing pump:

1. API type tubing pump is suitable for high wear wells (sandstone formation, sand content in the well).

2. Oil fields with slight corrosion but high requirements for API type tubing pump service life.

3. API tubing rod pumps are suitable for remote oil wells with limited technical personnel and the need to reduce the frequency of on-site maintenance.

4. API tubing rod pumps are suitable for economic cost-sensitive well sites, which need to extend the pump life cycle within the budget.

FAQ of oil sucker rod tubing pump:

Q1: What depth of well is this oil sucker rod tubing pump suitable for?

A: API sucker rod tubing pump supports a well depth range of 0-3000 meters, and can also be customized according to the customer's on-site well depth and working conditions.

Q2: Do special tools need to be maintained on site?

A: No, the oil sucker rod tubing pump adopts a standardized design and is compatible with conventional disassembly and assembly tools. General oilfield operation and maintenance personnel can complete basic operations.

Q3: Is it worth investing in a wear-resistant and corrosion-resistant oil sucker rod tubing pump?

A: From the perspective of a single purchase cost, the wear-resistant and corrosion-resistant pump is slightly higher, but the service life of the oil sucker rod tubing pump is about 2~3 times that of a conventional pump, and the overall cost is better.

Q4: Does the oil sucker rod tubing pump support different sizes of oil pipe interfaces?

A:Oil sucker rod tubing pump supports a variety of oil pipe diameter standards, including domestic conventional specifications and international general api specifications, which can be customized according to the actual needs of the project.

Why choose our API sucker rod tubing pump?

1. Strict quality inspection process: Each API sucker rod tubing pump, pump plunger, valve seat, and threaded parts are 100% inspected through three processes.

2. Coding traceability: Each API sucker rod tubing pump and component are numbered with oil tracks for easy after-sales and historical data tracking.

3. Stable supply and customized services: API sucker rod tubing pump supports on-demand design and rapid response to meet the needs of multi-well operations.