Elastic seal sucker oil well pump adopts an integral multi-stage sealing structure, each stage is independent of each other, and is forced to open and close, has an air-proof function, and eliminates the floating valve. The single-stage sealing unit adopts a non-contact elastic gap seal. Such a structure can not only reduce the sealing gap, reduce the leakage, and improve the pump efficiency, but also avoid pump jamming by changing the hard gap between the ordinary pump plunger and the pump barrel into an elastic gap. Elastic seal sucker rod pump for horizontal well can also avoid the damage of sand particles to the surface of the pump barrel and the plunger, and extend the pump inspection cycle. The fixed valve cover is provided with guide ribs, and the valve ball is forced to close under the action of the spring and the push rod.

Elastic seal sucker rod pump for horizontal well is suitable for various types of oil wells such as sand-producing oil wells, high-angle wells, horizontal wells, high-gas-containing oil wells, heavy oil wells, steam wells, steam drive wells, deep wells, etc.

1. Mechanical top seal rod pump adopts non-contact elastic gap seal and uses polymer composite sealing ring (temperature resistant to 200℃), which transforms the traditional hard gap into dynamic adaptive seal. The gap can be automatically adjusted with pressure changes (0.01-0.05mm), and the leakage is reduced by 70%.

2. The fixed valve of mechanical top seal rod pump is equipped with titanium alloy spring (lifespan>500,000 times) and push rod mechanism.

3. Mechanical top seal rod pump cancels the design of floating valve, eliminates the risk of gas lock, and is suitable for well conditions with gas-oil ratio>500m³/t.

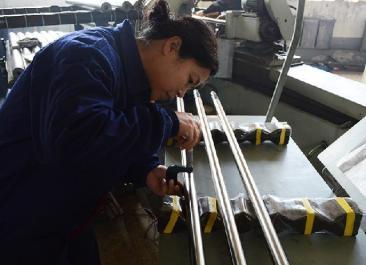

Every Dongsheng pump is subjected to a rigorous multi-stage QC process before shipment:

1.Material Verification: Spectrometric analysis of QT800-10 and Tungsten Carbide components.

2.Precision Measurement: 100% inspection of plunger-barrel clearance using digital air gauging.

3.Pressure Testing: Each pump undergoes a high-pressure leakage test exceeding 1.5x the rated working pressure.

4.API Compliance: Manufactured and tested in strict accordance with API Spec 11AX standards.

Site Condition:

Changqing Oilfield features complex well conditions with high sand content and low permeability. Traditional pumps often suffered from "Pump Jamming" due to sand accumulation.

Our Solution:

We deployed the Elastic Seal Sucker Rod Pump with specialized QT800-10 heat-treated components and a 45° spiral sand discharge groove.

The Result:

After 12 months of operation, the pump inspection cycle increased by 180%, and the production downtime caused by sand plugging was reduced to zero.

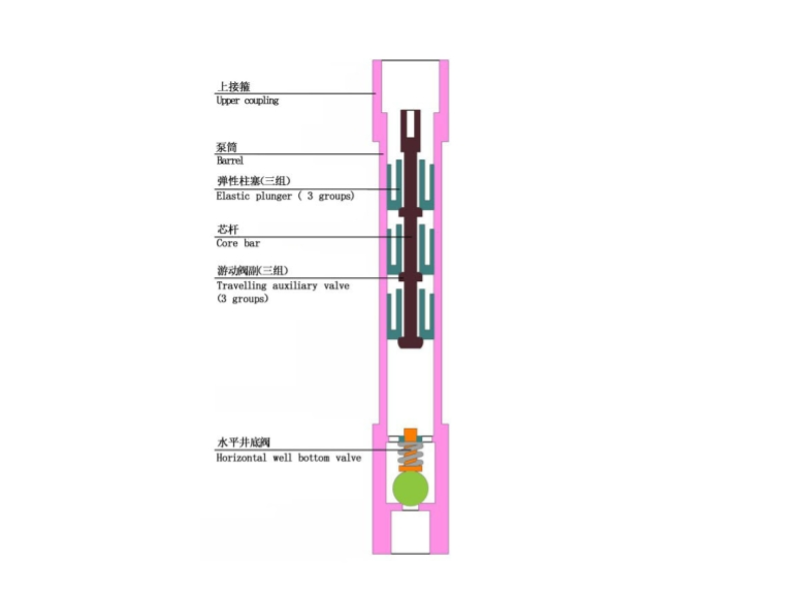

The core structure of elastic seal sucker rod pump for horizontal well includes;

Upper coupling: a key structure that connects the sucker rod and the pump body to achieve power transmission.

Barrel: the main pressure-bearing component that bears the pressure of the liquid column.

Elastic plunger (3 groups): adopts elastic structure design, and each group of plungers has adaptive deformation ability.

Core bar: the core support structure that runs through the plunger assembly to maintain the coaxial movement of the plunger components.

Travelling auxiliary valve (3 groups); used in conjunction with the elastic plunger to control the flow direction of the liquid in sections.

Horizontal well bottom valve: set at the bottom of the pump, with self-locking function to prevent liquid backflow.

| Pump bore (mm) | Length of plunger (m) | Length of barrel (m) | Range of stroke (m) | Pump constant of mechanical top seal rod pump | Size of connecting sucker rod | Size of connecting tubing (in ) | Max outside diameter (mm ) |

| 32 | 1.5 | 4.5~8.7 | 3.0~8.0 | 1. 14 | CYG19 | 2 3/8TBG or 27/8TBG | 73/89 |

| 38 | 1.64 | CYG19 | 2 3/8TBG or 27/8TBG | ||||

| 44 | 2. 23 | CYG19 | 2 7/8TBG or 3 1/2TBG | 89/108 | |||

| 57 | 3.69 | CYG19 | 2 7/8TBG or 3 1/2TBG | ||||

| 70 | 5. 52 | CYG22 | 3 1/2TBG or 4TBG | 108/121 | |||

| 83 | 7.70 | CYG22 | 3 1/2TBG or 4TBG | ||||

| 95 | 10.26 | CYG25 | 4TBG or 4 1/2TBG | 121/132 |

Certificates

Partners

Q1: What is the maximum displacement of horizontal well elastic seal sucker pump?

A: When the pump diameter is 95mm + 8m stroke, the theoretical displacement can reach 246m³/d (need to be matched with CYG25 sucker rod).

Q2: How to deal with the viscosity problem of heavy oil?

A:Horizontal well elastic seal sucker pump can be equipped with electric heating plunger (220V/3kW) to reduce the viscosity of crude oil from 5000mPa·s to 800mPa·s.

Q3: What certifications do your pumps hold?

A3: All our subsurface pumps are manufactured in strict accordance with API 11AX standards, and our factory is ISO 9001 certified. The replacement cycle is generally around 3 years.

About us:

Tieling Dongsheng Petroleum Machinery Co., Ltd. was established in 2000. It is a high-quality petroleum machinery manufacturer integrating design, manufacturing and trade. The company focuses on the research and development and production of special oilfield equipment such as rod pumps, tubing pumps, plungers, pump barrels, hard lining cages, etc. The products are widely used in the domestic market of China and overseas markets such as North America and the Middle East.

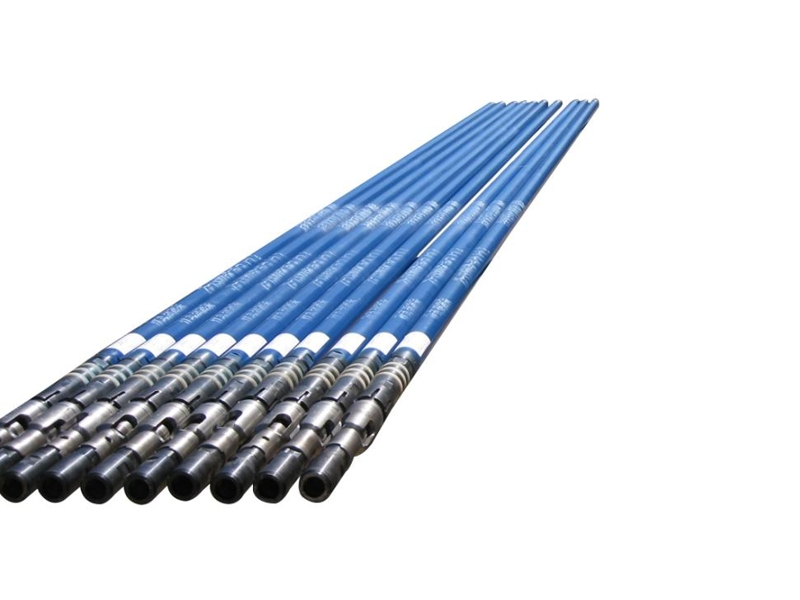

In terms of transportation safety, the company has formulated unified and strict packaging standards and loading and unloading specifications based on the particularity of petroleum machinery products. All mechanical top seal rod pump is professionally packaged and reinforced before leaving the factory, and anti-shock, moisture-proof and other protective measures are taken to ensure product quality and protect customer interests.