1. The bottom of the plunger of the thermal recovery sucker rod pump is inlaid with a diamond composite (PDC) scraping ring, and the inner wall of the pump barrel of the thermal recovery sucker rod pump is laser engraved with micron-level flow-guiding lines (Ra 0.8μm) to form a vortex effect to prevent sand deposition. 2. The plunger of the thermal recovery sucker rod pump is made of Inconel 718 alloy (temperature resistance 650℃),the seal of the thermal recovery sucker rod pump is a graphite-metal composite material. 3. The thermal recovery sucker rod pump adopts a floating valve seat design, which automatically compensates for the thermal deformation of ±3mm.

EmailMore

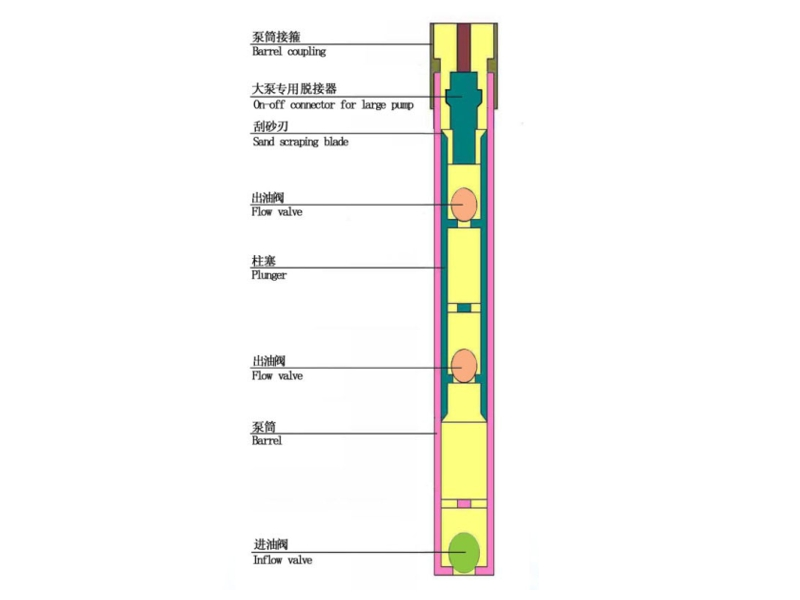

1. By changing the oil inlet valve to a circulating valve design, the circulating heavy oil well pump can improve the flow efficiency of the fluid and reduce the energy loss of the traditional pump. 2. Due to the use of a circulating valve and a short pump body design, the circulating heavy oil well pump can effectively prevent sand blockage during operation, and the circulating heavy oil well pump avoids downtime and equipment damage caused by sand blockage. Customers who use our products can enjoy higher reliability. 3. The circulating heavy oil well pump adopts a design of efficient oil inlet and reduced flow resistance, which makes the circulating heavy oil well pump consume less energy during operation, which meets the current requirements for energy consumption and environmental protection. Improve the green sustainability of production.

EmailMore