1. The inner wall of the long plunger sand control pump is chrome-plated (thickness 0.1-0.15mm), resistant to H₂S and CO₂ corrosion, and suitable for harsh environments with mineralization ≥10,000mg/L. 2. The long plunger sand control pump uses API standard threaded connections (such as 2 7/8 TBG), and plunger replacement can be completed without special tools. 3. The key components of the long plunger sand control pump are replaceable, such as the pump barrel, plunger, and valve group, which can be replaced independently to avoid overall scrapping and reduce maintenance costs by 40%.

EmailMore

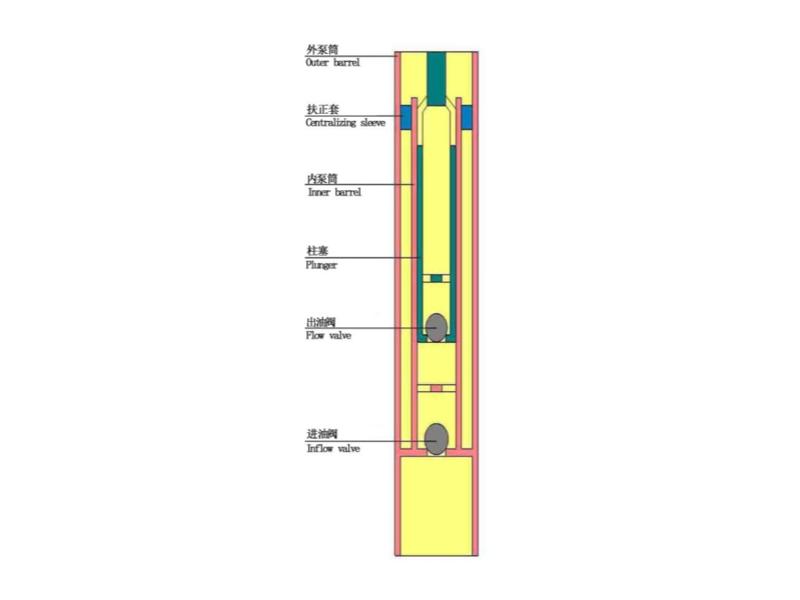

1. Thin oil well sucker oil pump adopts modular design. The core components such as pump barrel, plunger, valve and so on adopt standardized and independent module design, which is convenient for disassembly and replacement. 2. All parts of Thin oil well sucker oil pump can be replaced by conventional oilfield tools without special equipment. 3. Thin oil well sucker oil pump is suitable for low pressure, low liquid level and low liquid production wells, solving the problems of difficult start-up and unstable oil pumping of traditional pumps.

EmailMore

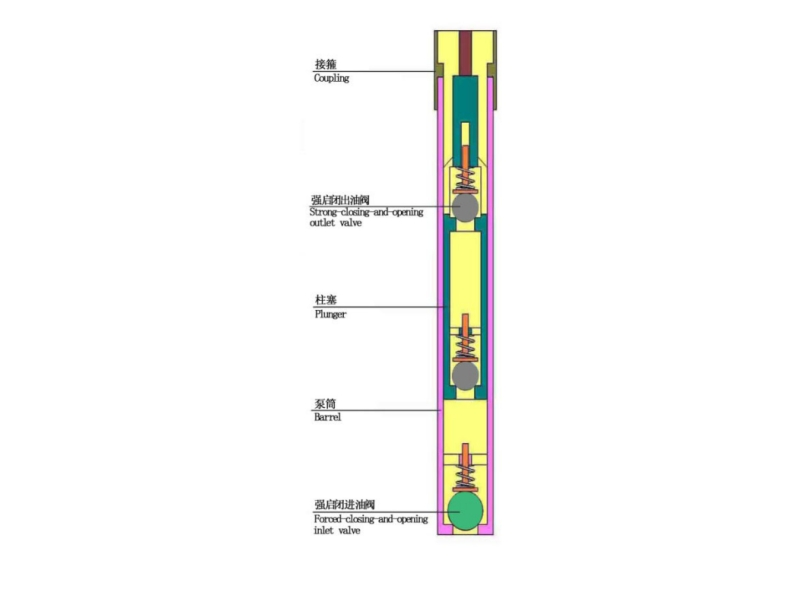

1. Our gas locking prevention oil well pump adopts a mechanical open-and-close oil inlet valve structure. When the gas enters the cavity of the gas locking prevention oil well pump, the pump valve automatically opens and closes by the reciprocating motion of the pump rod, effectively forcing the exhaust and stabilizing the fluid flow. 2. The inlet valve of the gas locking prevention oil well pump is made of high-strength corrosion-resistant alloy material. The gas locking prevention oil well pump avoids leakage or malfunction due to material fatigue. 3. The inlet valve of the gas locking prevention oil well pump adopts a streamlined guide channel design to make the fluid flow path smooth and continuous, reduce turbulence and resistance, and reduce the probability of release of dissolved gas in crude oil.

EmailMore

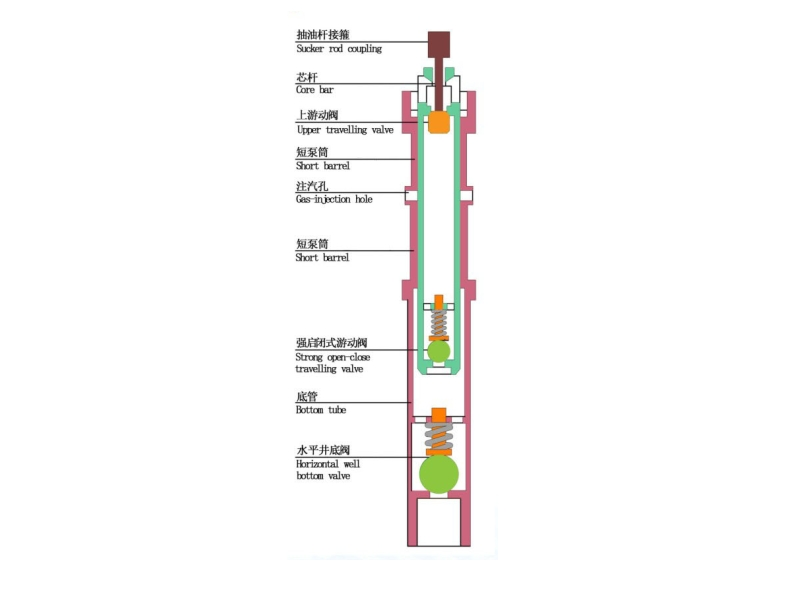

1. When the sucker rod is lifted 200mm, the plunger of the rod pump for steam injection thermal recovery is lifted synchronously through the mechanical linkage device to connect the steam injection hole of the sealing tube with the oil pipe. 2. The channel of the rod pump for steam injection thermal recovery adopts a high-temperature resistant alloy (Inconel 625) bushing, which can withstand continuous steam scouring at 350℃. In the field test of Liaohe Oilfield, the steam dryness retention rate is ≥85%. 3. When the plunger falls back, the cone surface (tolerance ±0.01mm) of the rod pump for steam injection thermal recovery forms a metal seal with the pump barrel, and the sealing pressure reaches 15MPa.

EmailMore

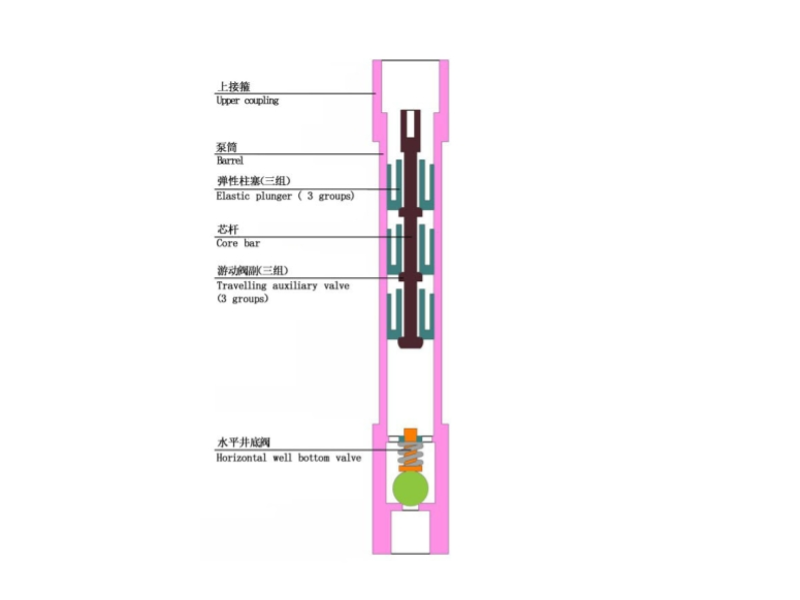

1. Optimized Sand Management: Featuring a unique 45° spiral guide groove design between sealing stages, our elastic seal pump increases sand discharge efficiency by 60%, significantly reducing pump plugging in high-sand environments. 2. Elastic seal sucker oil well pump uses all-metal structural parts with special heat treatment (QT800-10 material), which can maintain sealing performance under steam drive (350°C). 3. Elastic seal sucker oil well pump has built-in tungsten carbide guide sleeve (hardness HRA92), which is suitable for horizontal wells with well inclination angle ≤90°.

EmailMore

1. The bottom of the plunger of the thermal recovery sucker rod pump is inlaid with a diamond composite (PDC) scraping ring, and the inner wall of the pump barrel of the thermal recovery sucker rod pump is laser engraved with micron-level flow-guiding lines (Ra 0.8μm) to form a vortex effect to prevent sand deposition. 2. The plunger of the thermal recovery sucker rod pump is made of Inconel 718 alloy (temperature resistance 650℃),the seal of the thermal recovery sucker rod pump is a graphite-metal composite material. 3. The thermal recovery sucker rod pump adopts a floating valve seat design, which automatically compensates for the thermal deformation of ±3mm.

EmailMore

1. Our inclined well sucker rod pump adopts spring forced seat sealing technology, so our inclined well sucker rod pump solves the industry problem that the valve ball of traditional oil well pumps cannot return to its original position by gravity in inclined wells and horizontal wells. 2. Unlike ordinary oil well pumps that can only be used in vertical wells, our inclined well sucker rod pump can maintain stable operation at any angle of 0-90°. 3. The modular design of the inclined well sucker rod pump allows for quick replacement of pump diameter components (only 2 hours), and the same platform can adapt to different production capacity requirements of 32-95mm. 4. The special flow channel design of the inclined well sucker rod pump enables the viscosity adaptation range to reach 50-5000mPa·s.

EmailMore

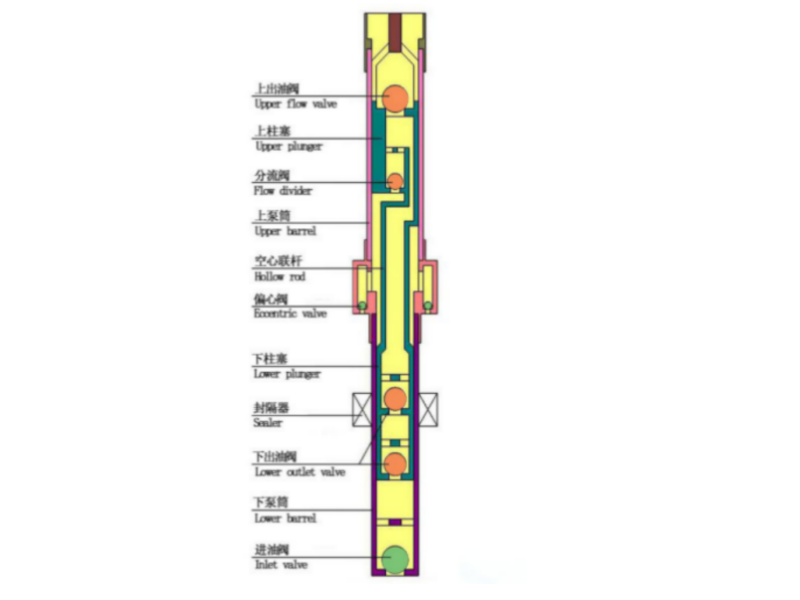

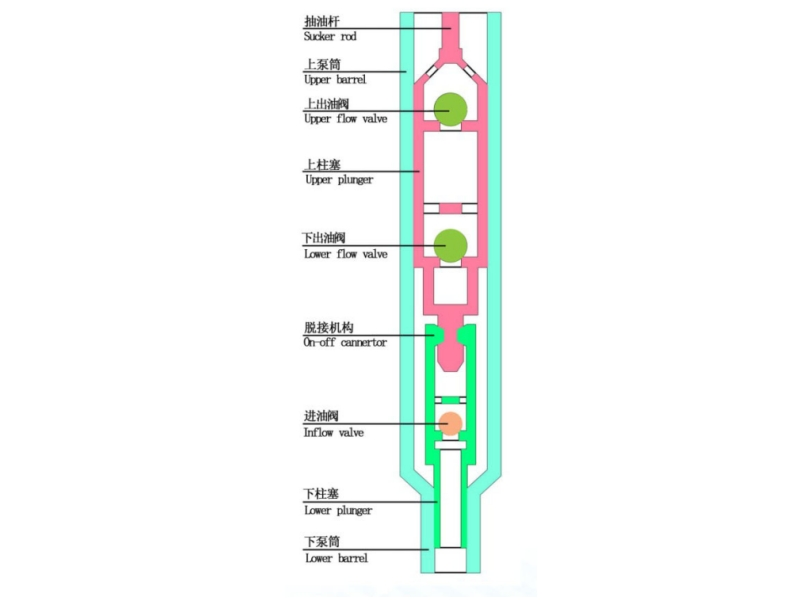

1.Large displacement tubing pump has dual working state switching function. Large displacement tubing pump can operate in two different working modes through the switch connector between the upper plunger and the lower plunger. 2.Due to this dual working state, the large displacement tubing pump can still maintain efficient operation under the condition of temperature and viscosity changes. When the wellhead temperature drops and the viscosity increases, the switch connector switches to the "open" position and continues to work efficiently. 3.When the large displacement tubing pump switch connector is in the "off" position, the displacement of the pump is the same as the size of the upper pump. When the large displacement tubing pump connector is switched to the "on" position, the displacement matches the oil inlet return pump, reducing energy loss.

EmailMore

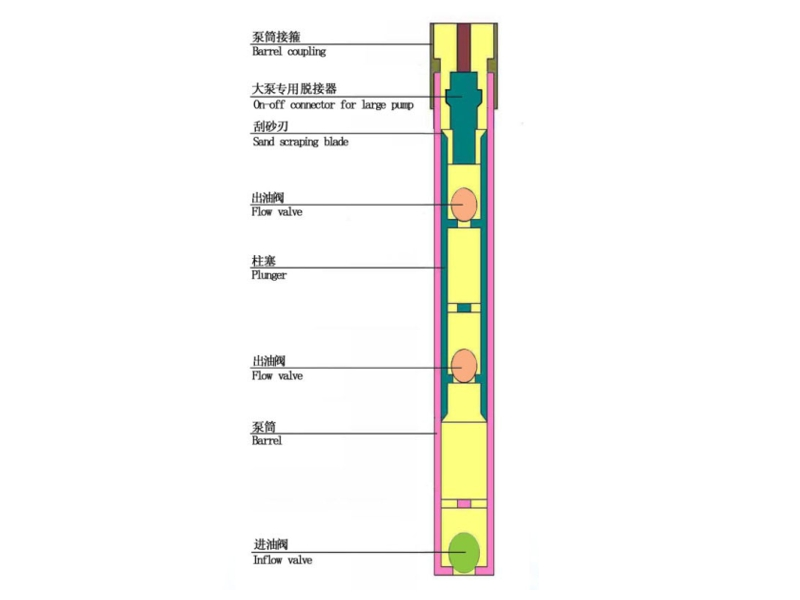

1. The surface of our sand scraping sucker rod well pump plunger is coated with high hardness and wear-resistant alloy (such as nickel-based alloy, tungsten carbide coating), and the inner wall of sand scraping sucker rod well pump is precisely polished to improve the hardness and smooth the surface, further reducing the adhesion and wear of sand particles. 2. The moving parts (plunger and pump barrel) of sand scraping sucker rod well pump are made of highly wear-resistant and corrosion-resistant materials, such as special alloy steel and stainless steel, and the surface of sand scraping sucker rod well pump is treated with high-frequency quenching or chemical plating. 3. In salt water and high H₂S environment, the pump barrel and plunger surface of sand scraping sucker rod well pump are treated with anti-corrosion composite coating, which effectively resists the corrosion of CO₂, H₂S and chloride ions in oil wells.

EmailMore

1. Our separate layer production oil well pump can be used to pump crude oil from multi-layer wells, which can greatly increase the single well production and crude oil recovery rate. 2. Our separate layer production oil well pump can exploit different oil layers separately, reduce inter-layer interference, and thus increase the overall production of the oil well. Our separate layer production oil well pump is particularly suitable for oil fields with uneven oil layer distribution or significant permeability differences. 3. Our separate layer production oil well pump has a simple pump string and convenient construction and operation.

EmailMore