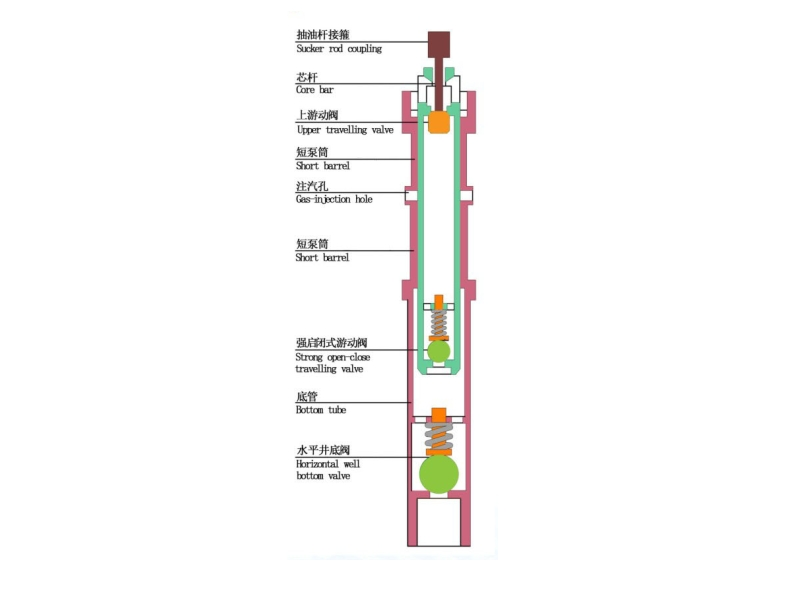

1. When the sucker rod is lifted 200mm, the plunger of the rod pump for steam injection thermal recovery is lifted synchronously through the mechanical linkage device to connect the steam injection hole of the sealing tube with the oil pipe. 2. The channel of the rod pump for steam injection thermal recovery adopts a high-temperature resistant alloy (Inconel 625) bushing, which can withstand continuous steam scouring at 350℃. In the field test of Liaohe Oilfield, the steam dryness retention rate is ≥85%. 3. When the plunger falls back, the cone surface (tolerance ±0.01mm) of the rod pump for steam injection thermal recovery forms a metal seal with the pump barrel, and the sealing pressure reaches 15MPa.

EmailMore

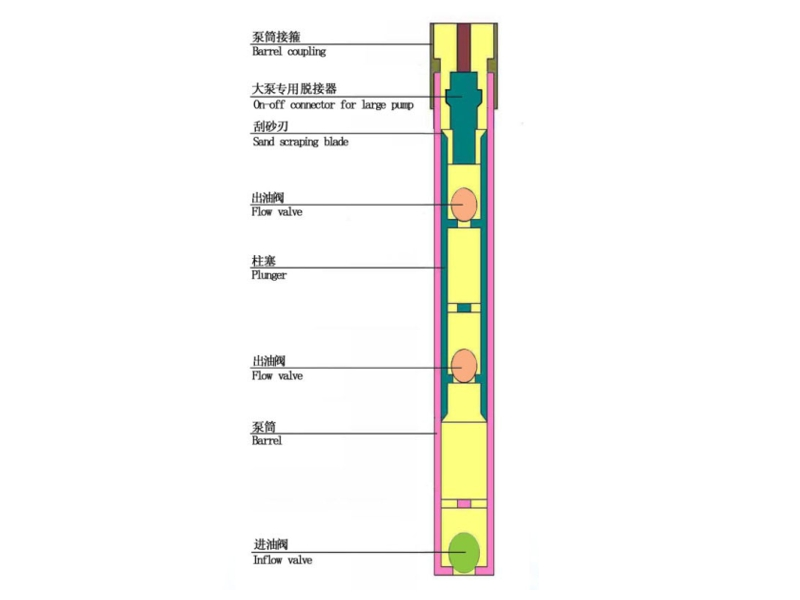

1. The bottom of the plunger of the thermal recovery sucker rod pump is inlaid with a diamond composite (PDC) scraping ring, and the inner wall of the pump barrel of the thermal recovery sucker rod pump is laser engraved with micron-level flow-guiding lines (Ra 0.8μm) to form a vortex effect to prevent sand deposition. 2. The plunger of the thermal recovery sucker rod pump is made of Inconel 718 alloy (temperature resistance 650℃),the seal of the thermal recovery sucker rod pump is a graphite-metal composite material. 3. The thermal recovery sucker rod pump adopts a floating valve seat design, which automatically compensates for the thermal deformation of ±3mm.

EmailMore