Introduction of thin oil well sucker oil pump:

The thin oil well sucker oil pump developed by our company adopts an innovative double-layer pump barrel structure. The deep well oil well pump is designed for deep thin oil well conditions. The deep well oil well pump is suitable for oil wells that cannot be normally produced due to insufficient formation fluid supply or low formation pressure in conventional lifting processes. The standard applicable well depth range is 2600 meters to 3500 meters. The deep well oil well pump has excellent sealing performance and anti-seizure ability, and can maintain efficient and stable operation under complex well conditions.

Working principle and structural advantages of deep well oil well pump:

The deep well oil well pump adopts a double-layer pump barrel design. During the upstroke of the plunger, the static pressure of the liquid column in the pipe acts on the outer wall of the outer barrel, effectively compressing the gap between the pump barrel and the plunger, reducing the pump efficiency loss caused by liquid leakage; During the downstroke of the deep well oil well pump, due to the balance of internal and external pressures, the deep well oil well pump can avoid the "pump expansion" phenomenon of traditional pumps, thereby extending the service life of the pump barrel and reducing maintenance costs.

The unique plunger anti-stuck structure design of the deep well oil well pump can cope with minor sanding and mechanical impurity interference in the well, prevent the pump stop problem caused by foreign matter stuck, and improve the overall system operation stability.

What practical benefits can our downhole sucker rod pump bring to you:

1. Downhole sucker rod pump adopts classic double-layer pump barrel structure design, with strong sealing and high pumping efficiency:

Technical principle: When the downhole sucker rod pump is in the upstroke, the outer wall of the pump barrel is subjected to the static pressure of the liquid column, automatically pressing the plunger, and the gap between the pump barrel and the plunger shrinks to reduce leakage.

Effect improvement: Downhole sucker rod pump can improve pump efficiency by more than 10%, reducing energy waste caused by liquid reflux.

Comparative advantage: Compared with the traditional single-layer pump barrel design, the downhole sucker rod pump structure is more adaptable to the high-pressure environment of deep wells, and the sealing performance is stable and not attenuated.

2. Automatic balance of internal and external pressures, effectively eliminating the "pump expansion" phenomenon:

Source of the problem: "pump expansion" is a structural deformation caused by the large pressure difference between the inside and outside of the pump barrel during the downstroke of the traditional pump, which is prone to fatigue damage.

Solution: The double-layer structure of the downhole sucker rod pump achieves automatic balance of internal and external pressures through pressure differential buffering.

Life extension: The life of the downhole sucker rod pump is increased by more than 30% on average, reducing the replacement frequency and maintenance costs.

3. Anti-stuck plunger structure, effectively dealing with mechanical impurities and mild sanding in the well:

Structural features: The plunger is equipped with an automatic guide and self-cleaning groove structure, which can actively release inclusions during operation.

Applicable working conditions: Downhole sucker rod pump is suitable for medium-difficult wells with occasional sanding and low impurity content in the well, but sufficient to cause jamming.

Effect verification: Field operation data shows that the downhole sucker rod pump can reduce plunger jam accidents by more than 80%.

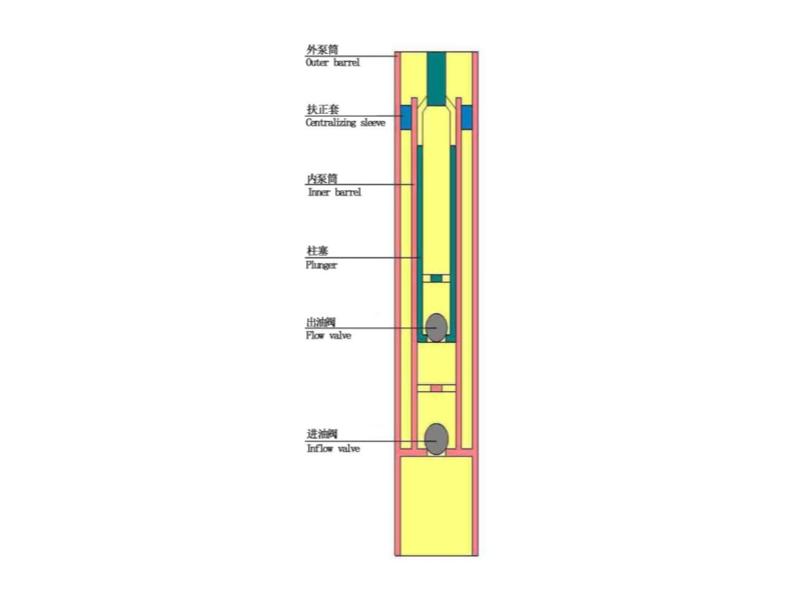

Structure diagram of deep well oil sucker rod pump:

The core structure of deep well oil sucker rod pump includes:

Outer barrel: Bears the static pressure of the liquid column and forms a double-layer sealing structure with the inner pump barrel.

Centralizer: Keeps the pump body vertical and reduces the friction of the wellbore wall.

Inner barrel: The actual liquid pumping channel, working with the plunger seal.

Flow valve: The liquid outlet valve is installed above the plunger and opens when the plunger strokes up.

Inflow valve: Allows liquid to enter the pump barrel to prevent backflow.

Technical parameters of thin oil well sucker oil pump:

Pump bore (mm ) | Range of stroke (m) | Pump constant of thin oil well sucker oil pump | Size of connecting sucker rod |

| Ø28 | 3.0~6.0 | 0.88 | CYG19 |

| Ø32 | 1.14 | ||

| Ø38 | 1.64 | ||

| Ø44 | 2.23 |

Applicable working conditions of deep well oil sucker rod pump:

Deep well oil sucker rod pump is suitable for oil wells with the following working conditions:

1. Deep well oil sucker rod pump for well drilling is suitable for wells with low formation permeability and poor fluid supply capacity;

2. Thin oil well sucker oil pump is suitable for wells with low formation pressure;

3. Deep well oil well pump is suitable for wells with low sand production or impurity content but easy to get stuck;

4. Deep well oil sucker rod pump for well drilling is suitable for medium-deep wells or deep wells that are difficult to achieve continuous production using conventional lifting technology.

About us:

Tieling Dongsheng Petroleum Machinery Co., Ltd. was established in 2000 and is a leading manufacturer of oil well pumps, deep well oil sucker rod pump for well drilling and downhole tools in China. The company has ISO9001 quality management system certification and API 11AX certification, and is committed to providing high-performance oil well pumps, special pumps, and deep well oil sucker rod pump for well drilling products for oil fields around the world. The factory covers an area of 20,000 square meters, has 96 employees, and produces more than 20,000 oil well pumps of various types annually. Deep well oil sucker rod pump for well drilling is exported to many countries such as the United States, Canada, and Indonesia, and widely serves major oil fields such as Liaohe, Daqing, Changqing, and Shengli. As a qualified supplier of CNPC, Sinopec, and Weatherford, we focus on technology innovation and quality control with the "Dongsheng" brand as the core to create greater value for customers.