1. The bottom of the plunger of the thermal recovery sucker rod pump is inlaid with a diamond composite (PDC) scraping ring, and the inner wall of the pump barrel of the thermal recovery sucker rod pump is laser engraved with micron-level flow-guiding lines (Ra 0.8μm) to form a vortex effect to prevent sand deposition. 2. The plunger of the thermal recovery sucker rod pump is made of Inconel 718 alloy (temperature resistance 650℃),the seal of the thermal recovery sucker rod pump is a graphite-metal composite material. 3. The thermal recovery sucker rod pump adopts a floating valve seat design, which automatically compensates for the thermal deformation of ±3mm.

EmailMore

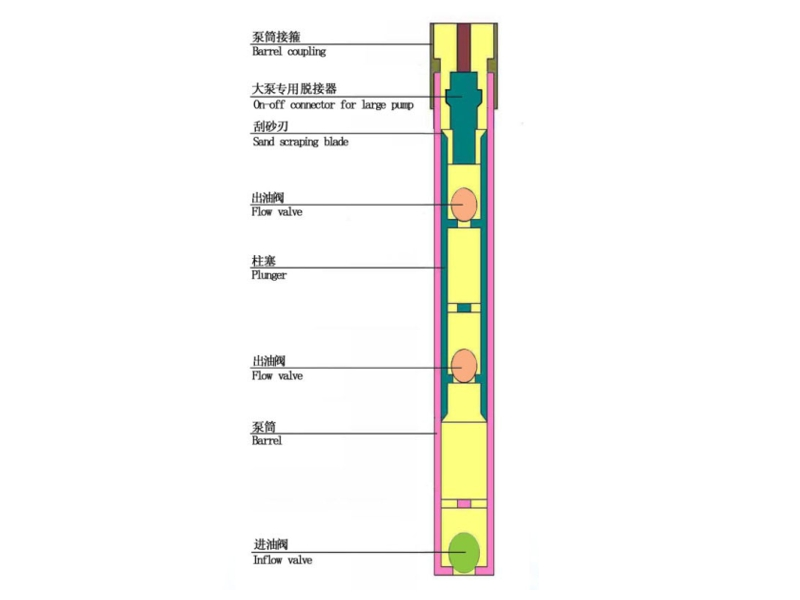

1. Our forced valve rod pump adopts mechanical forced valve design, the response speed of the traveling valve is increased by 80%, gas interference is effectively blocked, and the gas lock rate is reduced by 90%. 2. The forced valve rod pump is suitable for heavy oil wells with viscosity >10000 mPa·s, with a theoretical displacement of up to 800m³/d (83mm pump diameter), and an average daily increase of 35%-50%. 3. The stroke range of the forced valve rod pump is 2.0-6.0 meters, and the pump barrel length can be adjusted to 7.5 meters, which can easily cope with ultra-deep well conditions of 2000-5000 meters.

EmailMore