Introduction of rod pump for steam injection thermal recovery:

Primary string pump for steam injection thermal recovery is developed for the characteristics of heavy oil lifting. The normal working process of primary string pump for steam injection thermal recovery is different from that of ordinary pumps in that it can be used in special well conditions such as inclined wells and horizontal wells. When steam injection is required, the sucker rod is lifted up, and the plunger is also lifted up. When the plunger is about 200mm higher than the sealing cylinder, the steam injection hole on the sealing cylinder is connected to the upper oil pipe string, and the steam injection operation can be carried out.

After the steam injection operation is completed, the sucker rod is dropped back, and the plunger is also dropped back to the working position. At this time, the plunger enters the pump barrel and seals the steam injection hole. After adjusting the anti-collision distance, the primary string pump for steam injection thermal recovery can enter the working state. The thermal recovery sucker rod pump is the same as the whole barrel tubular oil pump pumping pump operation.

Advantages of thermal recovery sucker rod pump:

1. Special design for inclined wells/horizontal wells:

The inner wall of the pump barrel of the long plunger injection production downhole reciprocating pump adopts a spiral guide groove design, which can still ensure uniform lubrication of the plunger in the horizontal section, and can run continuously for more than 180 days without failure in a 83° high-angle well.

2. Steam injection:

The plunger surface of the long plunger injection production downhole reciprocating pump is plasma sprayed with Al₂O₃-TiO₂ composite coating with a hardness of HRC65. Under the condition of 2% sand content, the service life is 2.5 times that of traditional pumps

3. The long plunger injection production downhole reciprocating pump is directly connected to the API standard TBG tubing without the need for special tools, and the average pumping time is shortened to 4 hours (traditional thermal recovery pumps require 12 hours).

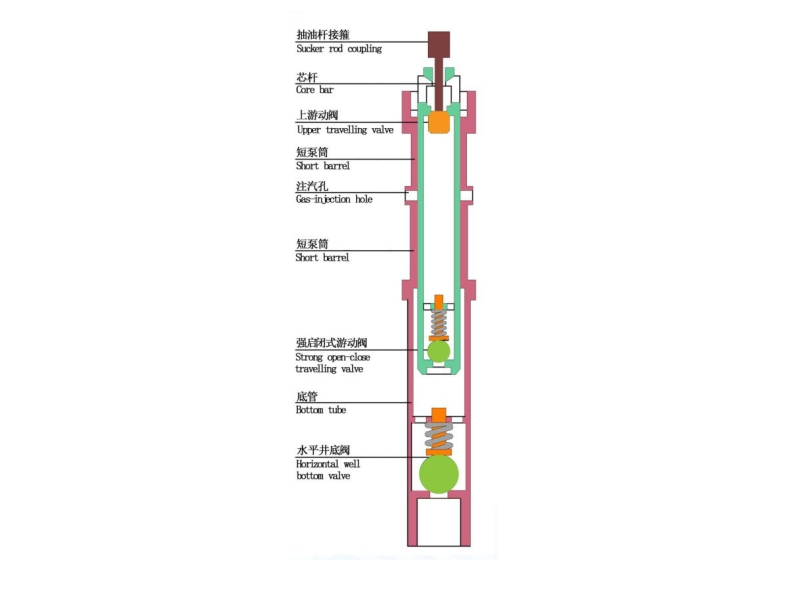

Structural diagram of injection and production pump:

The core structure of injection and production pump includes:

Sucker rod coupling:

Core bar:

Upper travelling valve:

Short barrel:

Gas injection hole:

Short barrel:

Strong open close travelling valve:

Bottom tube:

Horizontal well bottom valve:

All structures of injection and production pump are modularly designed, which is convenient for maintenance and replacement, reducing on-site operation time and operation and maintenance costs.

Technical parameters of injection and production pump:

Pump bore (mm ) | Length of plunger (m) | Length of barrel (m) | Size of connecting tubing (in ) | Range of stroke (m ) | Pump constant | Size of connecting sucker rod | Max outside diameter |

| 44 | 4.2~7.8 | 1.2+1.2 | 2 7/2TBG | 3.0-6 | 2.23 | CYG19 | 88.5 |

| 57 | 2 7/2TBG | 3.69 | CYG19 | 88.5 | |||

| 70 | 3 1/2TBG | 5.52 | CYG22 | 108 |

Note: Displacement calculation formula: Q = K × S × N.

(Q-daily displacement m³/d, K-pump constant, S-stroke m, N-strokes/min).

Application of thermal recovery sucker rod pump:

1. Heavy oil steam well: Primary string pump for steam injection thermal recovery can realize the whole cycle of "steam injection-well shut-down-production" without changing the pipe string.

2. Shale oil thermal recovery well: Injection and production pump cooperates with electric heating to realize super heavy oil recovery.

3. Thermal production increase of old well: economical and efficient secondary development plan.

4. Edge and bottom water heavy oil reservoir: Injection and production pump can accurately control the steam injection volume to avoid water invasion.

About us:

Technical team:

We have an experienced technical team, including 20 engineers and technicians, focusing on the structural optimization, material innovation and working condition adaptability of the oil well pump, to ensure that the product can maintain efficient and stable operation under extreme conditions.

Industry certification:

ISO 9001 quality management system certification

API 11AX international petroleum industry certification.

Qualified supplier qualification of PetroChina and Sinopec.

Packaging and logistics:

1. Professional packaging: Thermal recovery sucker rod pump adopts anti-rust oil + vacuum film double protection, and will not corrode during sea or long-distance transportation. Key components (such as plungers) are fixed separately to avoid collision damage.

2. Delivery: Conventional models are shipped within 2-4 weeks, and customized thermal recovery sucker rod pumps are shipped according to quantity. Supports multiple trade terms such as EXW/FOB/CIF, which can be reached worldwide.

3. Acceptance criteria: Each thermal recovery sucker rod pump undergoes a 72-hour pressure test and performance test before leaving the factory, and a quality inspection report, operation manual and certificate are provided with the goods.