Introduction of high gas cut well downhole pump:

The oil outlet valve of our high gas cut well downhole pump adopts a mechanical opening and closing structure. After the gas enters the interior of the high gas cut well downhole pump, the pump valve is driven by the pump parts to complete the opening and closing action, forcing the gas to enter the pump and be discharged out of the pump, completing the pumping process with the oil flow.

Our high gas cut well downhole pump overcomes the influence of gas on the operation of the oil outlet valve, prevents the impact of gas on the pump, and avoids the occurrence of "liquid hammer". The oil inlet valve of the high gas cut well downhole pump adopts a streamlined large flow channel structure to reduce the resistance of crude oil entering the pump, reduce the volatilization of crude oil dissolved gas, and reduce the influence of gas in the pump barrel on the pump efficiency. The high gas cut well downhole pump effectively solves the problem of high gas-containing oil well exploitation.

Advantages of high gas oil well rod pump:

1. The surface of the internal flow parts of the high gas oil well rod pump is precisely polished to further reduce friction, thereby maintaining fluid integrity and improving the finishing and conveying efficiency of the high gas oil well rod pump.

2. The pump barrel and plunger of the high gas oil well rod pump are made of high-strength carbonized materials, and local strengthening treatment is carried out in the easily worn area to effectively resist the erosion of tiny cavitation caused by cavitation.

3. The structure of the high gas oil well rod pump adopts a short-stroke high-frequency stroke design (stroke range 3-9 times/minute) to reduce the accumulation of bubbles during a single suction and discharge process, and further inhibit the occurrence of cavitation.

4. In view of the differences in well depths and gas-oil ratios of oil wells, our high gas oil well rod pump provides two pump diameter specifications of Φ44mm and Φ57mm, and is compatible with conventional 2 3/8TBG, 2 7/8TBG, and 3 1/2TBG connecting oil pipes, which can flexibly respond to various working conditions.

5. The pump barrel clearance (0.25-0.088mm) of the High gas oil well rod pump is precisely matched, and different specifications of High gas oil well rod pumps are set with different pump constants (2.23 or 3.69), which is convenient for accurate calculation of displacement and downhole operation design.

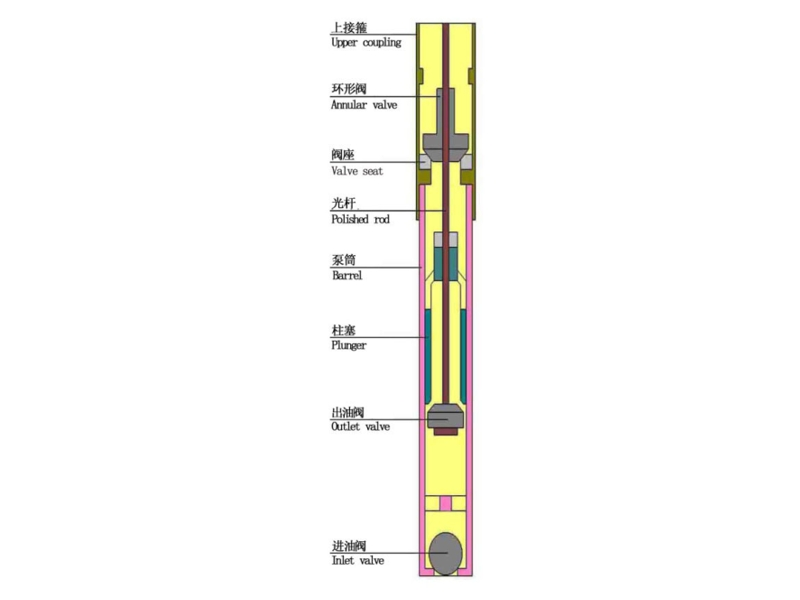

Structural diagram of high efficiency downhole rod pumps:

The core structure of high efficiency downhole rod pumps includes:

Upper coupling:

Annular valve:

Valve seat:

Polished rod:

Barrel:

Plunger:

Outlet valve:

Inlet valve:

All structures of high efficiency downhole rod pumps are modularly designed to facilitate maintenance and replacement, reducing on-site operation time and operation and maintenance costs.

Technical parameters of high efficiency downhole rod pumps:

Pump bore (mm ) | Fit clearance (mm ) | Range of stroke(m) | Stroke ( times/min ) | Pump constant | Depth (m) | Size of connecting tubing (in ) |

| Φ44mm | 0.025~0.088 | 1.2~6.0 | 3~9 | 2.23 | 1800~2000 | 2 3/8TB or 2 7/8TBG |

| Φ57mm | 0.025~0.088 | 1.2~6.0 | 3~9 | 3.69 | 1500~1800 | 3 1/2TBG |

Application of anti gas rod pump:

1. Anti gas rod pump can be used for deep wells, medium-deep wells, and high gas-oil ratio oil wells.

2. Anti gas rod pump can be used for production wells that need stable drainage and avoid gas lock and liquid hammer.

3. Anti gas rod pump can be used in oilfield projects facing the problem of reduced drainage efficiency of conventional oil well pumps.

Packaging of anti gas rod pump:

In order to prevent bumps, rust and pollution during transportation, our Anti gas rod pump adopts the following standard packaging methods:

1. Anti-rust treatment:

Rust-proof oil is applied to metal surfaces such as pump body, pump barrel, plunger, etc.

Important accessories of anti gas rod pump (such as liquid inlet valve and liquid outlet valve) are wrapped separately with anti-rust film.

2. Protective packaging of anti gas rod pump:

Main components are wrapped with bubble film + wrapping film for shockproof.

Accessories are individually packaged in sealed plastic bags, and small items are collected to prevent loss.

3. Outer box packaging of high gas cut well downhole pump:

Gas locking prevention oil well pump or components are packed in reinforced wooden boxes.

Customized support frames are added inside to prevent shaking and collision during transportation.

The outside of the wooden box is marked with obvious moisture-proof, shock-proof and anti-inversion signs.

4. Shipping method of high efficiency downhole rod pumps:

According to customer needs, sea, air or rail transportation can be arranged.

Partners:

Qualification Certificatio:

About us:

We are a source factory focusing on the research and development and manufacturing of anti gas rod pump and oilfield equipment. We have passed ISO 9001 quality management system certification and API 11AX international standard certification, quality assurance, and global recognition. Our company has a registered capital of 56 million yuan, an annual output of more than 20,000 oil pumps of various types, and supports large-scale delivery. In addition, we have a professional technical team and have long served large oilfield companies such as CNPC and Sinopec. Our high efficiency anti gas rod pump are exported to the Middle East, South America, Africa and other regions. Choose us, choose professionalism and reliability.