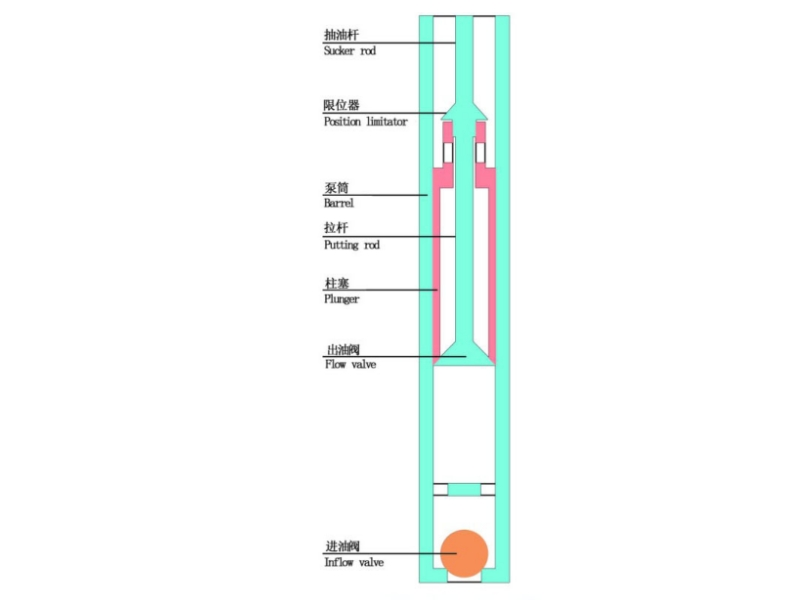

1. Our forced valve rod pump adopts mechanical forced valve design, the response speed of the traveling valve is increased by 80%, gas interference is effectively blocked, and the gas lock rate is reduced by 90%. 2. The forced valve rod pump is suitable for heavy oil wells with viscosity >10000 mPa·s, with a theoretical displacement of up to 800m³/d (83mm pump diameter), and an average daily increase of 35%-50%. 3. The stroke range of the forced valve rod pump is 2.0-6.0 meters, and the pump barrel length can be adjusted to 7.5 meters, which can easily cope with ultra-deep well conditions of 2000-5000 meters.

EmailMore

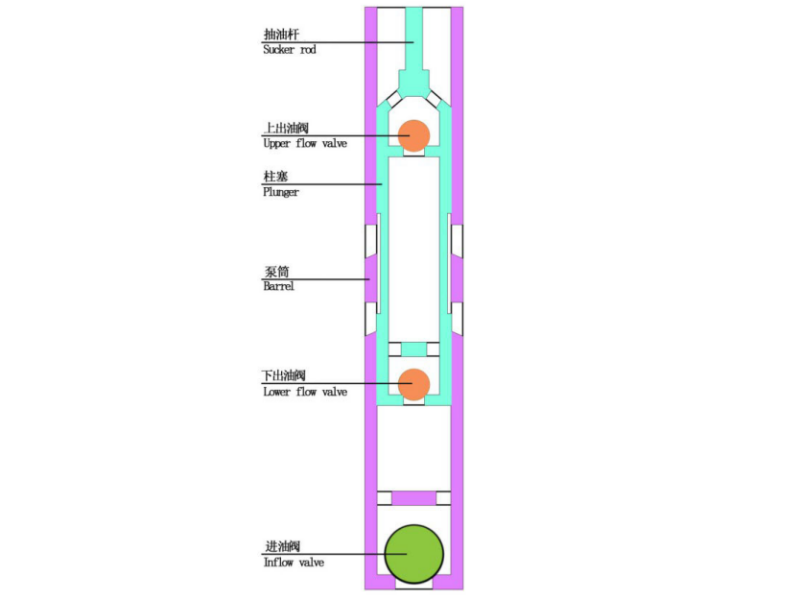

1. Our central exhaust double plunger series thickening oil well pump is equipped with an oil inlet exhaust groove in the middle, which is conducive to improving the filling coefficient of the pump and preventing the occurrence of gas lock. 2. Our central exhaust plunger oil well pumps for double-seal rod pump is widely used in gas wells or heavy oil wells. The design of our double plunger series thickening oil well pump can effectively cope with the mining needs under complex working conditions. 3. The design of our double plunger series thickening oil well pump can effectively prevent gas from occupying the pump chamber and maintain the normal operation of the pump.

EmailMore

1. Our strong opening and closing sucker oil pump has brought our customers stable operation, increased daily oil production, thousands of yuan in annual electricity bill savings, and reduced pump stoppage and maintenance times through large flow channel design, low-resistance opening and closing structure and precision matching parts. 2. The key components of the strong opening and closing sucker oil pump are made of hard alloy, which is wear-resistant and corrosion-resistant. Combined with reasonable structural design, the frequency of pump body replacement is reduced, which can save labor and production stoppage costs. 3. The strong opening and closing sucker oil pump has an automatic self-aligning function and modular structure, which can be flexibly adapted to vertical wells, inclined wells, deep wells and other well types. It is easy to disassemble and assemble on site without special tools. It is more economical to purchase and faster to maintain, reducing the difficulty and cost of well team operation and maintenance.

EmailMore

1. The on off tool packer is made of high-quality materials, and the key areas of the on off tool packer are made of thicker materials and surface hardened to achieve excellent strength. 2. The on off tool packer has special features of fatigue resistance, corrosion resistance, and wear resistance, reducing friction. 3. The on off tool packer enables workers to separate the rod column from the pump without stripping it while leaving the pump downhole, which is simple and convenient.

EmailMore

1. The columnar polished rod centraliser adopts a spiral groove structure design to reduce the sand burial and sand jam problems that are easy to occur in sand-containing oil wells. 2. The centralizing sleeve of the columnar polished rod centraliser can be divided into two materials: metal spray welding and nylon for your choice. 3. The columnar polished rod centraliser can prevent the formation of sediments inside the oil well pipe, so as not to increase the time for well maintenance.

EmailMore

1. Our hard-lined cage for rod pump meets industry standards and has passed API 11AX and ISO 9001 dual certification, with guaranteed quality. 2. Hard-lined cage for rod pump has the characteristics of corrosion resistance and wear resistance, and hard-lined cage for rod pump can be used in various environments. 3. We also provide customized services for carbide Cage for oil well, including size adjustment, material optimization, etc., to better meet the needs of different users.

EmailMore

1. The sliding sleeve scentralizer adopts a three-curved surface wear reduction design to change the traditional contact mode. The centralizer increases the contact area of the surface, makes the force more uniform, and improves the anti-eccentric wear performance. 2. The sliding sleeve centralizer is a downhole supporting device. The sliding sleeve centralizer can avoid eccentric wear damage between the sucker rod and the oil pipe and protect the integrity of the oil pipe. 3. The sliding sleeve sucker rod centralizer can center the sucker rod in the well to avoid metal-to-metal contact.

EmailMore

1. By changing the oil inlet valve to a circulating valve design, the circulating heavy oil well pump can improve the flow efficiency of the fluid and reduce the energy loss of the traditional pump. 2. Due to the use of a circulating valve and a short pump body design, the circulating heavy oil well pump can effectively prevent sand blockage during operation, and the circulating heavy oil well pump avoids downtime and equipment damage caused by sand blockage. Customers who use our products can enjoy higher reliability. 3. The circulating heavy oil well pump adopts a design of efficient oil inlet and reduced flow resistance, which makes the circulating heavy oil well pump consume less energy during operation, which meets the current requirements for energy consumption and environmental protection. Improve the green sustainability of production.

EmailMore

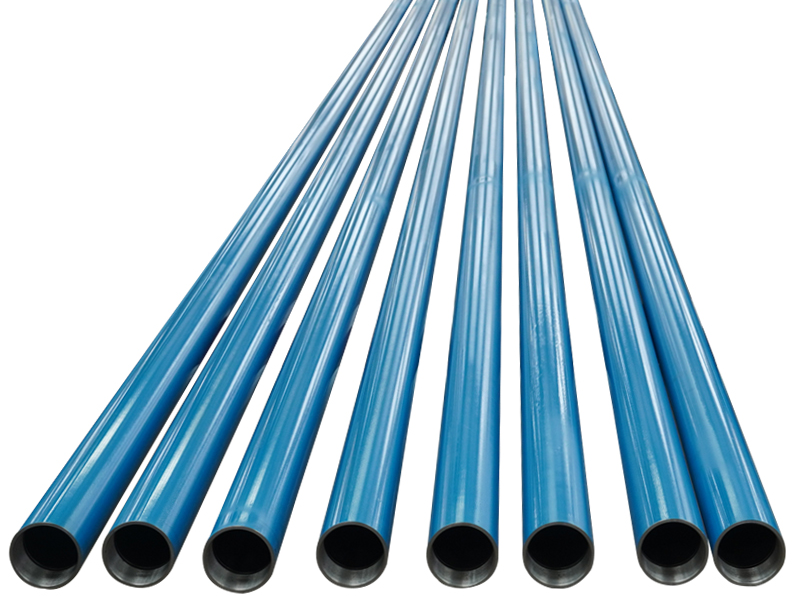

1. The hard chrome plating of our chrome plating carbon steel barrel has high hardness and better wear resistance than ordinary steel pipes, which effectively extends the service life of the downhole pump barrel and reduces the frequency of replacing the downhole pump barrel. 2. The plating surface of our chrome plating carbon steel barrel is precisely machined to perfectly fit the plunger, which is conducive to reducing medium leakage and improving overall efficiency. 3. The dense and non-porous chrome plating of our chrome plating carbon steel barrel can effectively resist water, oil and weak acid and alkali corrosion, adapt to humid and changeable environments, and ensure the long-term stable operation of the rod pump barrels.

EmailMore

1. Specialty spray metal plunger can effectively reduce oil leakage and can withstand long-term friction. 2. Specialty spray metal plunger has passed API 11AX and ISO 9001 standard certification, and the quality of special plunger is guaranteed. 3. The wear resistance and corrosion resistance of specialty spray metal plunger make it efficient and stable in oil drilling and mining.

EmailMore