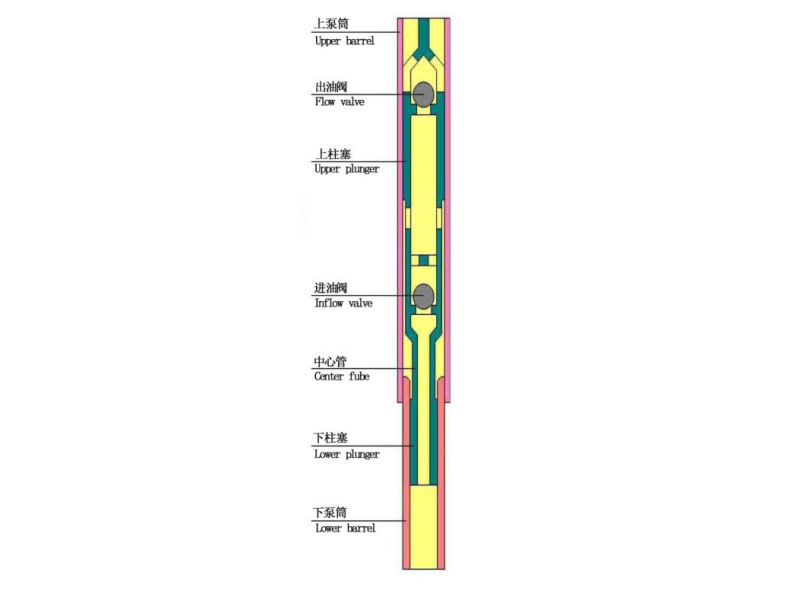

1. Upward stroke: When the plunger of the heavy oil pump with hydraulic feedback moves upward, the upper liquid enters the lower chamber through a specially designed feedback channel to form hydraulic energy storage. 2. Downward stroke: The stored hydraulic energy is converted into auxiliary thrust (actually measured up to 2-5kN), and the heavy oil pump with hydraulic feedback can effectively overcome the resistance of heavy oil. 3. Pressure balance design: The heavy oil pump with hydraulic feedback uses our original two-way flow channel structure to balance the pressure inside and outside the pump in real time to avoid air lock and sand jam.

EmailMore

1. Our strong opening and closing sucker oil pump has brought our customers stable operation, increased daily oil production, thousands of yuan in annual electricity bill savings, and reduced pump stoppage and maintenance times through large flow channel design, low-resistance opening and closing structure and precision matching parts. 2. The key components of the strong opening and closing sucker oil pump are made of hard alloy, which is wear-resistant and corrosion-resistant. Combined with reasonable structural design, the frequency of pump body replacement is reduced, which can save labor and production stoppage costs. 3. The strong opening and closing sucker oil pump has an automatic self-aligning function and modular structure, which can be flexibly adapted to vertical wells, inclined wells, deep wells and other well types. It is easy to disassemble and assemble on site without special tools. It is more economical to purchase and faster to maintain, reducing the difficulty and cost of well team operation and maintenance.

EmailMore