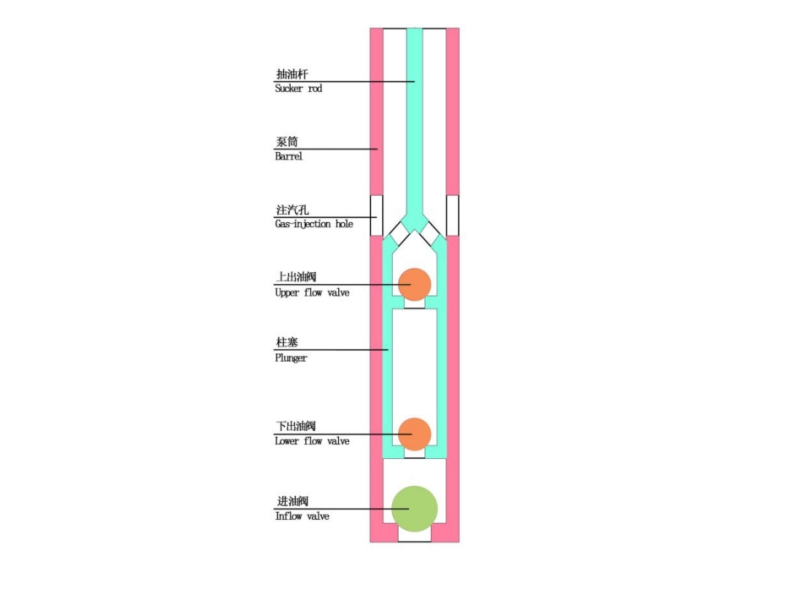

1. The bottom of the plunger of the thermal recovery sucker rod pump is inlaid with a diamond composite (PDC) scraping ring, and the inner wall of the pump barrel of the thermal recovery sucker rod pump is laser engraved with micron-level flow-guiding lines (Ra 0.8μm) to form a vortex effect to prevent sand deposition. 2. The plunger of the thermal recovery sucker rod pump is made of Inconel 718 alloy (temperature resistance 650℃),the seal of the thermal recovery sucker rod pump is a graphite-metal composite material. 3. The thermal recovery sucker rod pump adopts a floating valve seat design, which automatically compensates for the thermal deformation of ±3mm.

EmailMore

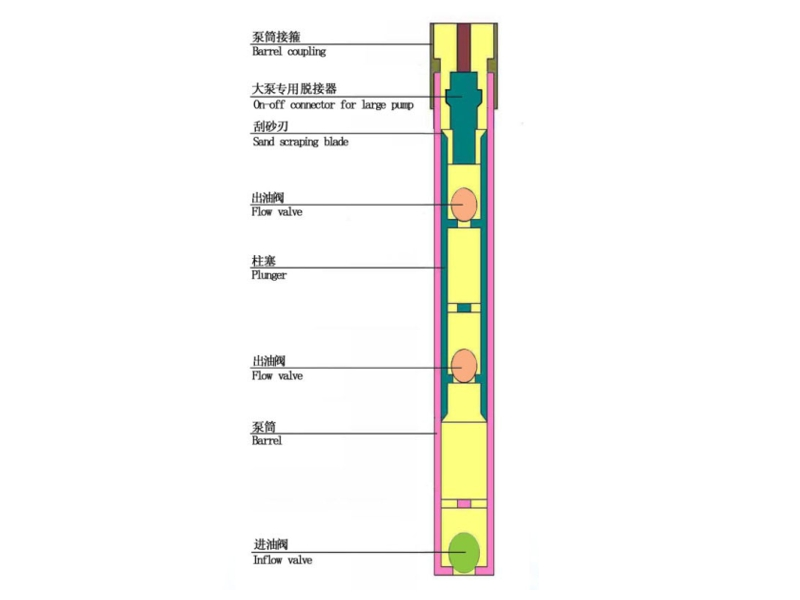

1. Sucker rod for high viscosity oil exploitation adopts 0.8m anti-stroke distance design + fluid mechanics optimization, which extends the equipment life by 50% and reduces the annual maintenance cost by 20,000 yuan. 2. Sucker rod for high viscosity oil exploitation has 4 pump diameters (32mm-57mm) to adapt to different well depths and oil products, reducing the comprehensive procurement cost by 25%. 3. Based on the Q=KSN formula, the stroke and stroke frequency are dynamically adjusted, and the theoretical displacement of sucker rod for high viscosity oil exploitation is up to 400m³/d.

EmailMore