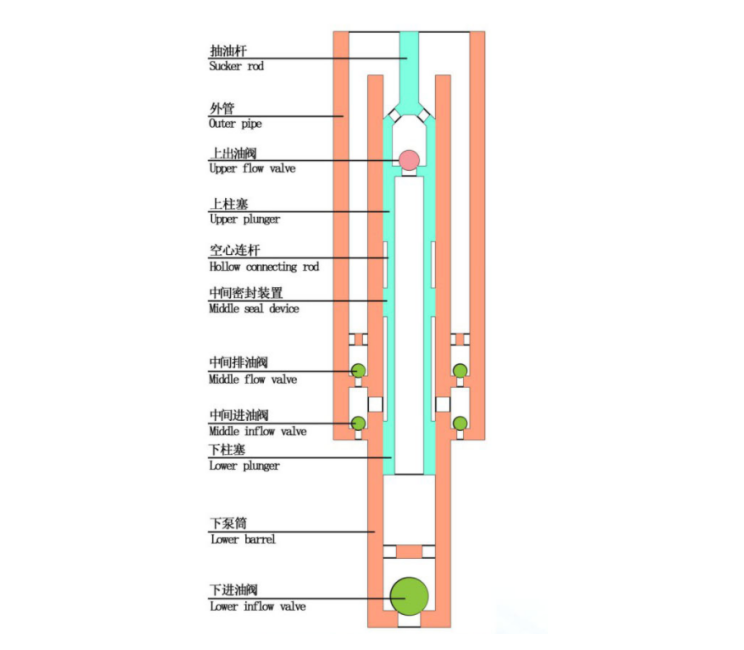

Introduction of Three-acting Tandem Oil Well Pump:

Three-acting large displacement tubing pump is composed of two pumps with the same pump diameter connected in series through a special structure, which are sealed in the middle and have intermediate inlet and outlet valves between the two pumps. The characteristic of triple acting sucker rod pump is that it discharges oil during both the up and down strokes, which can realize small pump and large displacement suction. Therefore, three-acting large displacement tubing pump is suitable for oil wells with sufficient liquid supply. The triple acting sucker rod pump is composed of a sucker rod, an outer tube, an upper oil outlet valve, an upper plunger hollow connecting rod, an intermediate sealing device, an intermediate oil discharge valve, an intermediate oil inlet valve, a lower plunger, a lower pump barrel and a lower oil inlet valve.

The Principle of Three-acting Large Displacement Tubing Pump:

The triple acting tandem sucker rod pump of our company, the upper pump barrel is installed in the outer tube, the lower part of the upper pump barrel is connected to the lower pump barrel, there is a sealing device between the upper pump barrel and the lower pump barrel, the intermediate oil outlet valve is installed between the lower part of the outer tube and the upper part of the lower pump barrel, there is an intermediate connecting hole on the upper part of the lower pump barrel, the intermediate oil inlet valve is installed between the lower part of the outer tube and the upper part of the lower pump barrel, the intermediate oil outlet valve is above the connecting hole, and the intermediate oil inlet valve is below the connecting hole. The lower part of the lower pump barrel of the triple acting tandem sucker rod pump is installed with a lower oil inlet valve, the sucker rod, the upper oil outlet valve, the upper plunger, the hollow connecting rod, and the lower plunger are connected in sequence, the triple acting sucker rod pump There is an upper cavity between the upper plunger and the sealing device, an upper connecting hole is provided on the upper part of the hollow connecting rod, and the upper connecting hole connects the upper cavity with the hollow connecting rod. There is a hollow cavity between the sealing device and the lower plunger, and the hollow cavity is connected to the lower part of the intermediate oil outlet valve by the connecting hole. There is a lower cavity between the lower plunger and the lower oil inlet valve of the triple acting sucker rod pump. The displacement is large, which can increase the oil well production. The size is small, suitable for implementation in ordinary casing, and has a wide range of applications.

Data of Triple Acting Sucker Rod Pump:

Pump | Length of plunger (m ) | Length of barrel ( m ) | Range of stroke (m) | Size of connecting tubing ( in ) | Size of connecting tubing ( in ) | Size of connecting sucker rod | constant of triple acting tandem sucker rod pump | Max outside diameter | ||

57 | Upper | Lower | Upper | Lower | 2.1~3.6 | 3 TBG | CYG19 | 3 TBG | CYG19 | 114 |

0.9 | 0.9 | 3.7~5.2 | 3.3~4.8 | |||||||

About Us:

As an advanced domestic oil pump manufacturer, our company is committed to the design, development, manufacture and supply of oilfield products such as rod pumps, special rod pumps ,triple acting tandem sucker rod pump and downhole tools. Our company is a qualified material supplier for China National Petroleum Corporation, China Petrochemical Corporation and Weatherford. We can produce more than 20,000 oil pumps and special oil pumps annually. In the future, we will continue to produce better products and provide you with more choices.