Introduction of heavy oil recovery downhole pump:

The heavy oil recovery downhole pump has hydraulic feedback force when working, which can help the plunger to move downward. The heavy oil recovery downhole pump is particularly suitable for heavy oil well production. When the crude oil viscosity is below 4000 centipoise, it can be directly pumped without viscosity reduction. The heavy oil recovery downhole pump has no fixed valve, and the oil drainer is not required in the well. It can also be used for parallel testing and steam injection thermal recovery without moving the pipe column. In addition, the heavy oil recovery downhole pump has an average daily output of 6.8m³, and the pump inspection cycle is 198 days.

Advantages of super heavy oil injection and production downhole pump:

1. Our super heavy oil injection and production downhole pump adopts direct suction technology and special flow channel design to increase the shear rate by 300%, and can handle heavy oil with viscosity up to 4500CP.

2. The surface of the plunger of the super heavy oil injection and production downhole pump adopts nano-diamond composite coating (friction coefficient <0.08), and the wear resistance is increased by 5 times.

3. The super heavy oil injection and production downhole pump has no fixed valve structure, reducing 50% of wearing parts, and the maintenance cycle is extended to 18 months.

4. Special sucker rod pump to handle sand and gas in heavy oil wells has thermal recovery compatibility, and can directly perform steam injection operations, saving thermal recovery well transformation time.

5. Special sucker rod pump to handle sand and gas in heavy oil wells also adopts sand prevention design, and the secondary spiral filtration system (filtration accuracy 0.3mm) reduces the sand jam failure rate by 80%.

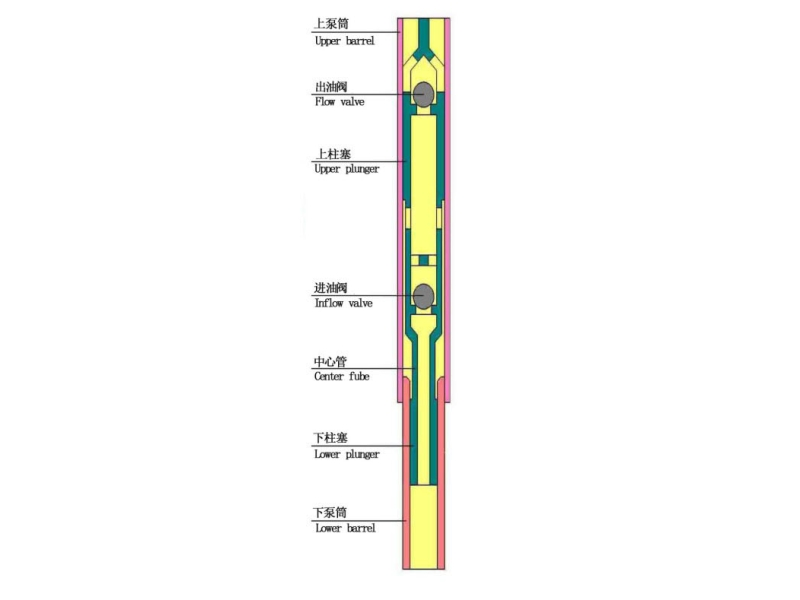

Structural diagram of heavy oil pump with hydraulic feedback:

The core structure of special sucker rod pump to handle sand and gas in heavy oil wells includes:

Upper battel:

Flow valve:

Upper plunger:

Inflow valve:

Center fube:

Lower plunger:

Lomer barrel:

All structures of special sucker rod pump to handle sand and gas in heavy oil wells are modularly designed, which is convenient for maintenance and replacement, reducing on-site operation time and operation and maintenance costs.

Technical parameters of hydraulic feedback sucker rod pump:

Pump bore (mm ) | Length of plunger (m) | Length of barrel (m) | Size of connecting tubing ( in ) | Pump constant | Size of connecting sucker rod | Size of connecting tubin g(in ) |

57/38 | 0.6~1.2 | 2.7~6.6 | 1.8~5.1 | 1.91 | CYG19 | 2 7/8 TBG |

| 70/38 | 3.91 | CYG22 | 3 TBG | |||

| 70/44 | 3.35 | CYG22 | 3 TBG | |||

| 83/44 | 5.60 | CYG25 | 3 1/2TBG | |||

| 83/57 | 4.25 | CYG25 | 3 1/2TBG |

Application of hydraulic feedback sucker rod pump:

1. Heavy oil: Hydraulic feedback sucker rod pump can replace screw pump, saving 60% maintenance cost.

2. High condensate oil field: Hydraulic feedback sucker rod pump does not need electric heating, direct cold production.

3. Sandy conglomerate heavy oil reservoir: Special sand control design ensures long-term operation.

4. Marginal heavy oil resources: Hydraulic feedback sucker rod pump reduces the economic threshold of mining by 30%.

5. Thermal recovery to conventional wells: Smooth transition of production stage.

FAQ:

1. How to calculate the actual displacement? What parameters are required?

Answer: Use the formula Q=K×S×N, where:

K (pump constant): See the technical parameter table.

S (stroke): unit meter.

N (strokes): times/minute.

*Note: It is recommended to take 70-85% of the theoretical displacement for heavy oil conditions.

About us:

We have 17 patents related to oil well pumps, such as hydraulic feedback, strong opening and closing valves and other core technologies. The product covers -30℃~350℃ extreme working conditions and is suitable for heavy oil with a viscosity of up to 4000 centipoise. The modular design reduces maintenance costs (it only takes 2 hours to replace key components). Compared with screw pumps, energy consumption is reduced by 30%, and the return on investment period is shortened to 6 months. More than 5,000 units have been used in Liaohe, Shengli, Xinjiang and other oil fields. Household cases show an average increase in production of 20%~45%, and the pump inspection cycle is extended by 2~3 times.