Introduction of standard oil sucker rod:

Our Dongsheng standard oil sucker rod is mainly suitable for oil wells with high crude oil viscosity and steam injection (viscosity reduction) devices at the wellhead. Standard oil sucker rod can realize the steam injection and pumping cycle without moving the pipe column. When injecting steam (or other viscosity reducers), lower the plunger to "touch the pump" and steam can be injected into the bottom of the well through the steam injection hole. When pumping, the upper anti-thrust distance is 0.8 meters, and it can work normally.

Advantages of gasoline injection well rod pump:

1. Standard oil sucker rod directly acts on the bottom of the well through steam injection (or viscosity reducer) at the wellhead, quickly reducing the viscosity of crude oil and avoiding the inefficiency or frequent blockage of traditional oil pumps due to crude oil viscosity.

Customer value: Improve oil pumping efficiency. Using standard oil sucker rod can increase the daily output of a single well by 20%-30% (based on pump constant and stroke optimization), while reducing the maintenance cost caused by shutdown and blockage removal. The annual operation and maintenance cost of standard oil sucker rod is reduced by about 15%.

2. Thermal rod pump does not need to move the pipe string, and switches between steam injection and pumping mode with one button. The original "pump collision" design only requires lowering the plunger to inject steam. The thermal rod pump is switched to the pumping mode by lifting the 0.8-meter anti-shock distance. There is no need to disassemble or adjust the pipe string during the whole process.

Customer value: The operation time is shortened by 70%. The traditional steam injection and pumping takes 4-6 hours, and our thermal rod pump only takes 30 minutes to complete the switch.

3. Accurate anti-impact distance design extends the life of the thermal rod pump by 50%. The 0.8-meter anti-impact distance has been verified by fluid mechanics simulation to reduce mechanical wear.

Customer value: The failure rate of the thermal rod pump is reduced by 60%, and the maintenance cycle is extended from 3 months to 6 months, saving more than 20,000 yuan in spare parts replacement costs per well per year.

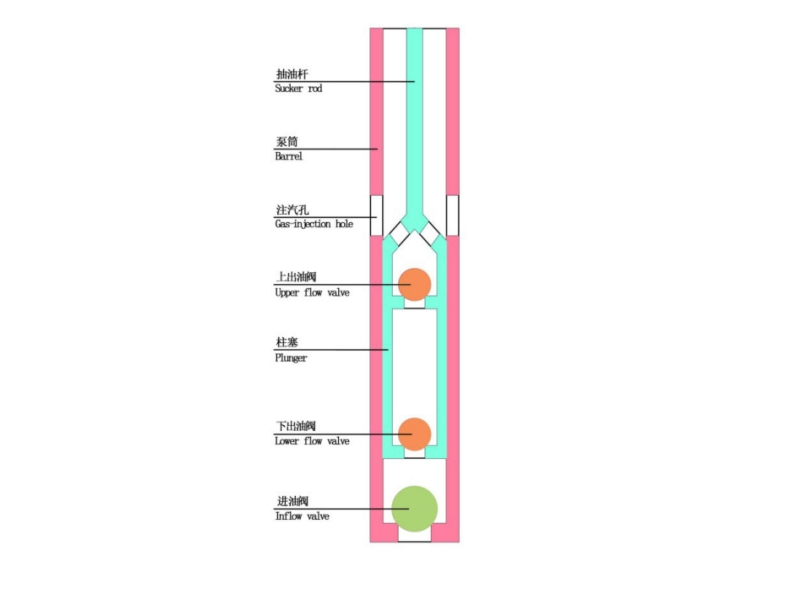

Structural diagram of thermal rod pump:

The core structure of thermal rod pump includes:

Sucker rod:

Barrel:

Gas iniection hole:

Upper flow valve:

Plunger:

Lower flow valve:

Inflow valve:

All structures of thermal rod pump are modularly designed, which is convenient for maintenance and replacement, reducing on-site operation time and operation and maintenance costs.

Technical parameters of thermal rod pump:

Pump bore (mm ) | Length of plunger (m) | Length of barrel (m) | Size of connecting tubing (in ) | Range of stroke (m ) | Pump constant | Size of connecting sucker rod |

| 32 | 1.5+1.5 | 6.0~7.8 | 2 7/8TBG | 2.4~3.3 | 1.14 | CYG19 |

| 38 | 2 7/8TBG | 1.64 | ||||

| 44 | 2 7/8TBG | 2.23 | ||||

| 57 | 2 7/8TBG or 3TBG | 3.69 |

FAQ of gasoline injection well rod pump:

How to choose the pump diameter of gasoline injection well rod pump according to the viscosity of oil?

1. Viscosity <5000 mPa·s: 32/38mm pump diameter (flexible displacement, suitable for medium and low viscosity).

2. Viscosity 5000-10000 mPa·s: 44mm pump diameter (balance efficiency and power consumption).

3. Viscosity >10000 mPa·s: 57mm pump diameter (large displacement forced suction to avoid pump blockage).

About us:

In order to ensure the timely delivery of gasoline injection well rod pump, the company has built a professional logistics system, using efficient road transportation domestically and providing sea and air transportation internationally, so that global customers can receive goods quickly and safely. All Gasoline injection well rod pump and other series of equipment are professionally packaged for shockproof and moisture-proof before leaving the factory, providing solid protection for on-site use in oil fields.