Introduction of sand well recovery sucker rod pump:

Sand well recovery sucker rod pump adopts fixed plunger and moving pump barrel structure. Sand well recovery sucker rod pump has the advantages of simple structure, streamlined flow channel, sucker rod is not easy to break, plunger is not easy to be stuck and buried in sand, corrosion resistance, wear resistance, long service life, etc. Sand well recovery sucker rod pump is suitable for oil wells with serious sand production.

Advantages of sand control and centralize rod pump:

1. The wear resistance of our sand control and centralize rod pump is improved by more than 30%, and the corrosion rate is reduced by more than 50%. Compared with traditional materials, the single well operation cycle is extended by 1.5 to 2 times.

2. The sand control and centralize rod pump adopts a streamlined pump barrel cavity, with no dead corners inside, smooth liquid flow, and reduced sand settling and vortex phenomena. The flow resistance is reduced by about 15%, the stroke energy utilization rate is higher, and the energy consumption of pumping is reduced by 5%-10% under the same conditions.

3. The sand control and centralize rod pump adopts a highly reliable anti-break design, and the pump barrel has a light moving mass and small inertia.

4. The anti-sand centralizing rod pump uses a reinforced sucker rod (CYG19 standard), and the tensile and compressive loads are reasonably distributed during the pumping process, which significantly reduces the risk of broken rods and tripping.

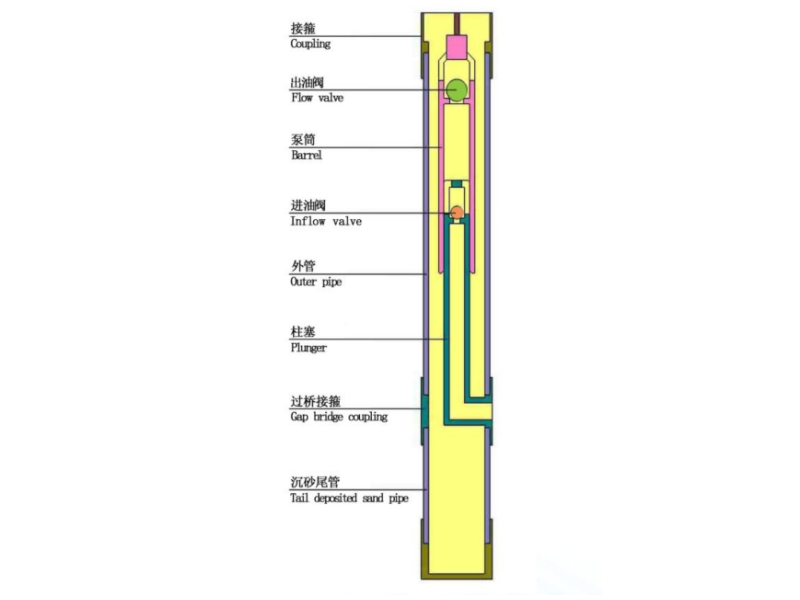

Diagram structure of anti-sand centralizing rod pump:

The core structure of anti-sand centralizing rod pump includes:

Coupling:

Flow valve:

Barrel:

Inflow valve:

Outer pipe:

Plunger:

Gap bridge coupling:

Tail deposited sand pipe:

All structures of anti-sand centralizing rod pump are modularly designed, which is convenient for maintenance and replacement, reducing on-site operation time and operation and maintenance costs.

Technical parameters of movable barrel sand control oil well pump:

Pump bore (mm ) | Length of plunger (m) | Length of barrel (m) | Size of connecting tubing (in ) | Range of stroke (m ) | Pump constant | Size of connecting sucker rod | Max outside diameter |

| 38 | 1.1 | 4.5、6.6 | 3 1/2TBG | 4.5-6 | 1.64 | CYG19 | 100 |

| 44 | 3 1/2TBG | 2.23 | CYG19 | 100 | |||

| 57 | 4 TBG | 3.69 | CYG19 | 108 or 114 |

Application of movable barrel sand control oil well pump:

1. Movable barrel sand control oil well pump is suitable for various complex working conditions such as high sand content oil wells, highly corrosive wells, and old wells.

Packaging and delivery of movable barrel sand control oil well pump:

Packaging: Each movable barrel sand control oil well pump is reinforced with a special anti-collision wooden box, and the interior is treated with anti-rust oil seals to prevent damage and corrosion during transportation.

Delivery: Supports various international trade methods such as fob and cif, and supports delivery in multiple ports.

FAQ of anti-sand centralizing rod pump:

1: Do you have a quality control system?

A: Yes, Anti-sand centralizing rod pump have passed ISO 9001 quality management system certification and obtained permission to use API 11AX certificate.

2: Are you a factory or a trader?

A: We are a manufacturer. As a leading pump manufacturer in China, we are committed to designing, developing, manufacturing and supplying oilfield products such as sucker rod pumps, Sand Well Recovery Sucker Rod Pump, special sucker rod pumps and downhole tools, etc.

3: Can we provide customized services?

a:Yes, we can customize according to your needs.

4: What about the production and delivery time?

A:The production time depends on the quantity of Sand Well Recovery Sucker Rod Pump. After you place an order, we will produce it as soon as possible. The delivery time depends on your country and port.

About us:

Currently, our company has 116 employees, including 20 senior engineers and technicians, and we are also recruiting outstanding talents. We are the source factory of sand control and centralize rod pump manufacturers, supporting direct transactions, reducing intermediaries, allowing customers to purchase high-quality products at a better price, and enjoy timely and professional technical support and after-sales service. In addition, our company has long provided products and services to large oilfield companies such as China National Petroleum Corporation and Sinopec. Products such as sand control and centralize rod pump are widely used in many oilfield projects at home and abroad. Customers are spread across important oil and gas producing areas such as the Middle East, Central Asia, South America, and Africa, and have won a good reputation and long-term cooperative relations.