Introduction of Separate Production Oil Pump:

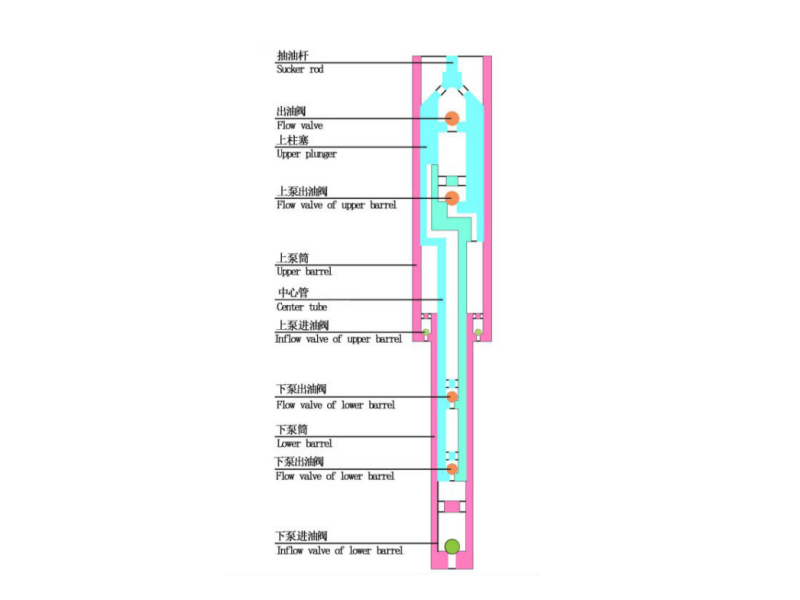

Our company's Separate production oil pump is a double-pump single-acting oil pump. The upper and lower pumps of the dual channel oil well pump work at the same time. The upper pump uses the annular space formed by the difference in the diameter of the upper and lower plungers to work. The upper oil enters the space through the upper pump inlet valve and then is discharged through the upper pump outlet valve. The lower oil enters the lower pump barrel through the lower pump inlet valve, and then is discharged from the lower pump outlet valve, mixed with the upper oil and discharged from the ground together. The pump is suitable for stratified production of oil wells. The structure of the dual channel oil well pump is: the oil outlet valve, upper plunger, upper pump oil outlet valve, upper pump barrel, central pipe, upper pump oil inlet valve, lower pump oil outlet valve, lower pump barrel, lower pump oil outlet valve and lower pump oil inlet valve work together.

Data of Layered Oil Production Sucker Pump:

Pump bore | Length of plunger | Length of barrel | Size of connecting Tubing | Range of Stroke | Pump | Size of connecting | Max outside |

57/38 | 0.6~1.2 | 2.1~7.5 | 2 7/8 TBG | 1.2~6.0 | 3.54 | CYG19 | 116 |

70/38 | 3 TBG | 5.54 | CYG22 | ||||

70/44 | 3 TBG | 6.10 | CYG22 | ||||

83/44 | 3 1/2TBG | 7.79 | CYG25 | ||||

83/57 | 31/2TBG | 9.14 | CYG25 |

Advantages of Dual Channel Oil Well Pump:

1. The dual channel oil well pump can quickly complete the oil pumping task, save time, avoid secondary pollution, and improve hygiene and health levels.

2. The dual channel oil well pump can continuously output a stable amount of oil. The equipment can automatically sense the required amount of oil, add oil at a fixed time and quantity, ensure the stability of the oil amount, and facilitate operation.

3. The Separate layer production oil well pump does not lift the oil pipe, which can save operation time, reduce operation costs, and reduce the wear of the oil pipe thread caused by the installation and removal of the buckle.

4. The Separate layer production oil well pump only lifts the sucker rod column during operation, which reduces the operation risk.

5. Separate layer production oil well pump is used in packer isolation wells to avoid frequent sealing and unsealing of packers.

Transportation, Loading and Unloading and Storage of Separate Layer Production Oil Well Pump:

1. Separate layer production oil well pump is a long and precise equipment. We will pay attention to stable lifting and lowering during loading and unloading, and take measures to prevent collision and falling to avoid damage. The oil production tool sucker pony rod will be protected with a cap or cotton cloth to support the sealing assembly during transportation to prevent damage to the sealing surface.

2. When we transport it by car, we will install the oil production tool sucker pony rod on the bracket and fix it. The pump rack should be placed steadily and avoid stacking as much as possible, and fix it to prevent it from falling during transportation.

3. When we transport it on site in the oil field, we will install the oil production tool sucker pony rod on a special horizontal bracket and transport it by a special vehicle. The distance between adjacent fulcrums on the bracket shall not exceed 1.5 meters. Before transporting the oil production tool sucker pony rod to the well site, we will insert the oil pump into a new oil pipe to prevent damage to the seal caused by collision.

Service Guarantee:

Our company's oil production tool sucker pony rod has passed the ISO9001 quality management system certification and obtained the API11AX certificate. We provide you with high-quality after-sales guarantee, solve your problems on the dual channel oil well pump, and formulate your own solutions for your doubts. Choosing Dongsheng means choosing peace of mind!