Introduction of large pump diameter sucker rod pump:

There is a disconnect mechanism between the upper and lower plungers of our large pump diameter sucker rod pump, which makes the large pump diameter sucker rod pump have two different working states. When the heavy oil well is steam injected and then pumped out, the disconnect mechanism can be placed in the "disconnected" position. At this time, the working principle and discharge volume of the large pump diameter sucker rod pump are the same as those of the large pump above, thereby realizing large pump diameter pumping. When the temperature of the oil well drops and the viscosity of the crude oil increases, the disconnect mechanism can be placed in the "connected" position. At this time, the working principle and discharge volume of the large pump diameter sucker rod pump are the same as those of the feedback pump with the same pump diameter, thereby realizing feedback pumping. The pump can also realize steam injection without moving the tubing column.

Advantages of large displacement sucker rod pump:

1.Large displacement sucker rod pump can automatically adjust to different environmental conditions and adapt to changing well temperature and viscosity by switching the connector position.

2.Our design is based on precise fluid mechanics and pump body optimization. The design of large displacement sucker rod pump allows the pump to automatically adjust its displacement according to changes in the working environment. Through this design, customers who use our large displacement sucker rod pump not only reduce energy consumption, but also maintain the efficient operation of the pump when the oil field environment changes. When running for a long time, it can significantly reduce the overall operating cost and bring sustainable economic benefits.

3.Our large displacement sucker rod pump integrates temperature and viscosity feedback mechanisms, which can sense the working status of the oil well in real time and automatically adjust the working parameters of the pump according to the properties of the oil. No manual intervention is required for pump adjustment, which reduces the difficulty of operation. Large displacement sucker rod pump adopts advanced wear-resistant materials and precision processing technology. Key components such as switch connectors, plungers, pump bodies, etc. Have been rigorously designed and repeatedly tested. There is no need to frequently replace parts or perform maintenance, which reduces downtime and additional maintenance costs. Reduce the frequency and cost of overall equipment replacement.

5. Through the simplified operation interface and clear identification design of the large displacement sucker rod pump, operators can make adjustments quickly and intuitively. The switch position and operation mode of the pump are clear at a glance, and the operation is simple and does not require complex training. Each control point of the large displacement sucker rod pump has been carefully designed to make the adjustment process quick and safe.

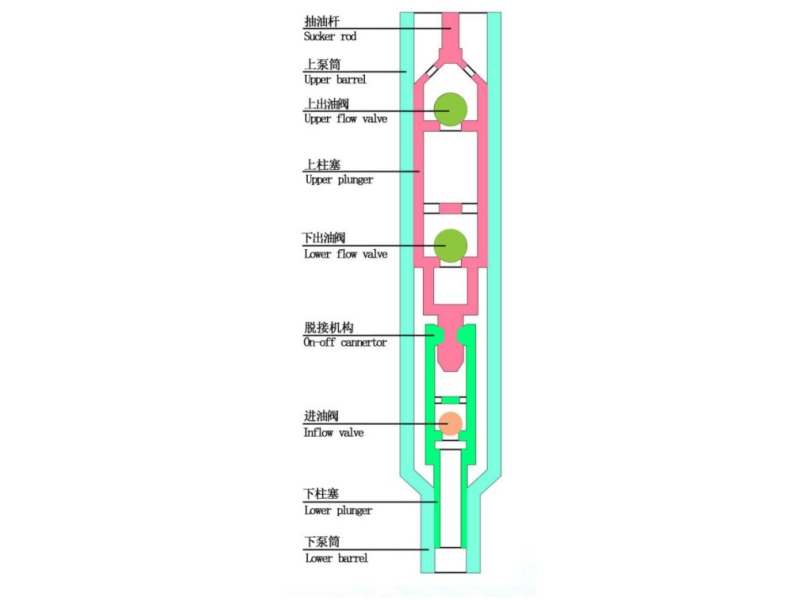

Structural diagram of large displacement tubing pump:

The core structure of large displacement tubing pump includes:

Sucker rod:

Upper barrel:

Upper flow valve:

Upper plunger:

Lower flow valve:

On off cannertor:

Inflow valve:

Lower plunger:

Lower barrel:

All structures of large displacement tubing pump are modularly designed, which is convenient for maintenance and replacement, reducing on-site operation time and operation and maintenance costs.

Technical parameters of large pump diameter sucker rod pump:

Pump bore (mm ) | Length of plunger ( m ) | Length of barrel ( m ) | Range of stroke | Size of connecting tubing | Size of connecting sucker rod | Pump constant | |||

Upper lunger | Lower plunger | Upper barrel | Lower barrel | "off" position | "on" position | ||||

57/38 | 0.9 | 0.9 | 3.6~6.9 | 3.3~6.6 | 1.8~5.1 | 2 7/8 TBG | CYG19 | 3.54 | 1.91 |

70/38 | 3 TBG | CYG22 | 3.54 | 3.91 | |||||

| 70/44 | 3 TBG | CYG22 | 3.54 | 3.35 | |||||

About us:

Tieling Dongsheng Petroleum Machinery Co., Ltd. was established in 2000. It is a leading oil well pump manufacturer in China, focusing on the design, development and manufacturing of oilfield pumping equipment and downhole tools. The company is a qualified supplier of large enterprises such as PetroChina, Sinopec and Weatherford, with an annual output of more than 20,000 oil well pumps and special pumps. It covers an area of 20,000 square meters, is equipped with 20 technical backbones, and has strong R&D and production capabilities.