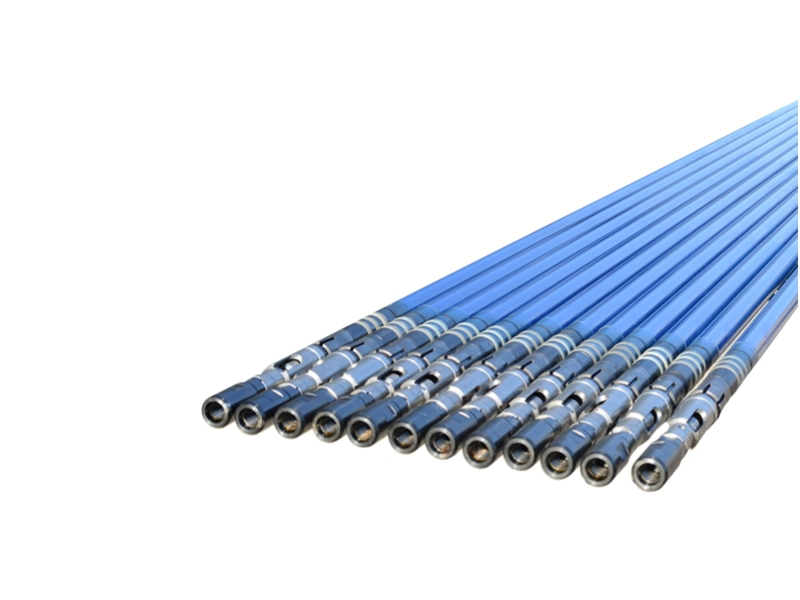

Introduction of inclined well insert pump:

Our inclined well insert pump uses the thrust of the spring to force the valve ball to seal on the valve seat sealing surface so that the oil pump can work normally even in a horizontal state. Sucker rod pump for inclined well solves the problem that the valve ball cannot fall back to the valve seat by gravity when the inclined well insert pump is in an inclined or horizontal working state. The inclined well insert pump has the advantages of simple structure, reliable performance, low operating cost, and high pump efficiency. The inclined well insert pump is widely used in oil production operations in inclined wells and horizontal wells.

Advantages of forced open close inclined well pump:

1. Sucker rod pump for inclined well adopts an integrated spring-loaded valve ball system. Compared with complex hydraulic or electric solutions, forced open close inclined well pump reduces the number of vulnerable parts by 80%.

2. The spring material of forced open close inclined well pump is made of high-strength alloy steel, which can maintain elastic properties in corrosive environments after special heat treatment process.

3. Through the precisely calculated spring preload (range of 5-15N), the valve ball of forced open close inclined well pump can be sealed in time and completely at any angle.

4. The valve seat of forced open close inclined well pump is made of tungsten carbide, and the sealing surface with the valve ball is precisely ground, with a surface roughness of Ra0.2μm.

5. Sucker rod pump for inclined well adopts a specially designed sand prevention structure (secondary filtration system) to reduce the wear of sand particles on the pump by 70%, and the plunger surface adopts super-hard coating technology, which extends the service life by 3 times.

According to our customer cases, the average annual maintenance cost per well is reduced by $15,000, and the return on investment period is shortened to 6 months.

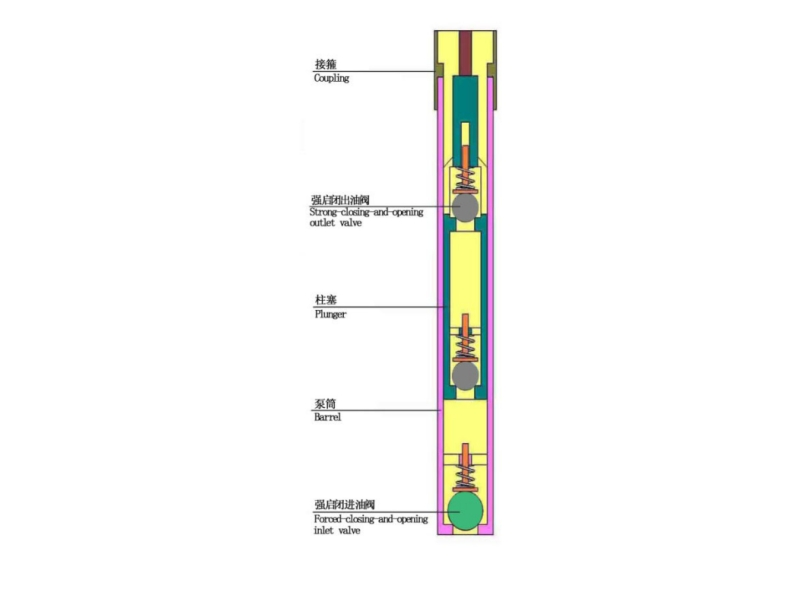

Structural diagram of sucker rod pump for inclined well:

The core structure of sucker rod pump for inclined well includes:

Coupling:

Strong closing and opening outlet valve:

Plunger:

Barrel:

Forced closing and opening inlet valve:

All structures of sucker rod pump for inclined well are modularly designed, which is convenient for maintenance and replacement, reducing on-site operation time and operation and maintenance costs.

Technical parameters of inclined well insert pump:

Pump bore ( mm ) | 32 | 38 | 44 | 57 | 70 | 83 | 95 |

Length of plunger (m) | 0.6~1.5 | ||||||

Range of stroke (m) | 3.0~6.0 | ||||||

| Pump constant | 1.14 | 1.64 | 2.23 | 3.69 | 5.52 | 7.70 | 10.26 |

| Max outside diameter(mm) | 89.5 | 90.1 | 114.3 | 118 | 132.5` | ||

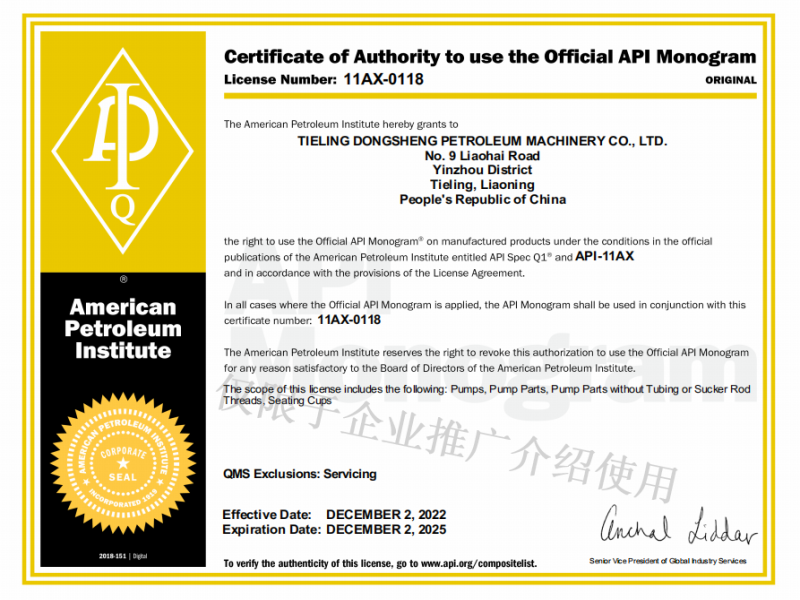

API certification of inclined well pump:

1.Our Inclined Well Sucker Rod Pumps are manufactured in strict accordance with API Spec 11AX, and their quality is recognized internationally.

2.Our API 11AX standardized design—the structure, dimensions, and materials of our Inclined Well Insert Pumps fully comply with API specifications.

3.Our Inclined Well Pumps utilize precision-machined components made of wear-resistant and corrosion-resistant alloys to extend pump life.

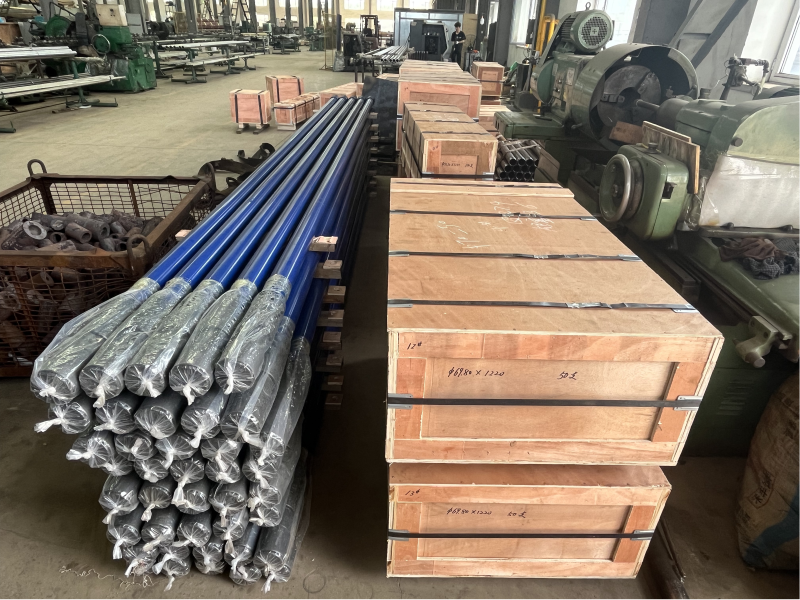

Shipping site:

We have successfully completed the shipment of a batch of oil well pumps and accessories to Canadian customers. This batch of equipment has been strictly produced, inspected and packaged in our workshop and is packed in reinforced wooden boxes that meet international transportation standards to ensure safety during long-distance transportation.

Cooperating customers:

Applications of inclined well pump:

1. High-angle directional wells: Inclined well pump replaces electric submersible pumps in wells with an inclination angle of 45-85°, saving 40% energy.

2. Horizontal well segmented production: Inclined well pump cooperates with packers to achieve multi-stage production, increasing the recovery rate by 15%.

3. Heavy oil thermal production wells: High temperature resistant design adapts to steam huff-and-puff operation cycle.

4. High sand content oil wells: Special sand control structure ensures stable operation in wells with sand content ≤3%.

5. Low permeability oil fields: Small pump diameter models are suitable for economical production of low-yield wells.

About us:

Tieling Dongsheng Petroleum Machinery Co., Ltd. is a leading domestic professional manufacturer of oil well pumps, focusing on the research, development, production and sales of rod pumps, special oil well pumps and downhole tools. The company has a registered capital of 56 million yuan and an annual production capacity of more than 20,000 units. Its products are widely used in complex working conditions such as heavy oil, inclined wells, horizontal wells and thermal wells. It is a core supplier of large energy companies such as PetroChina and Sinopec. At the same time, we are very much looking forward to cooperating with more overseas customers!