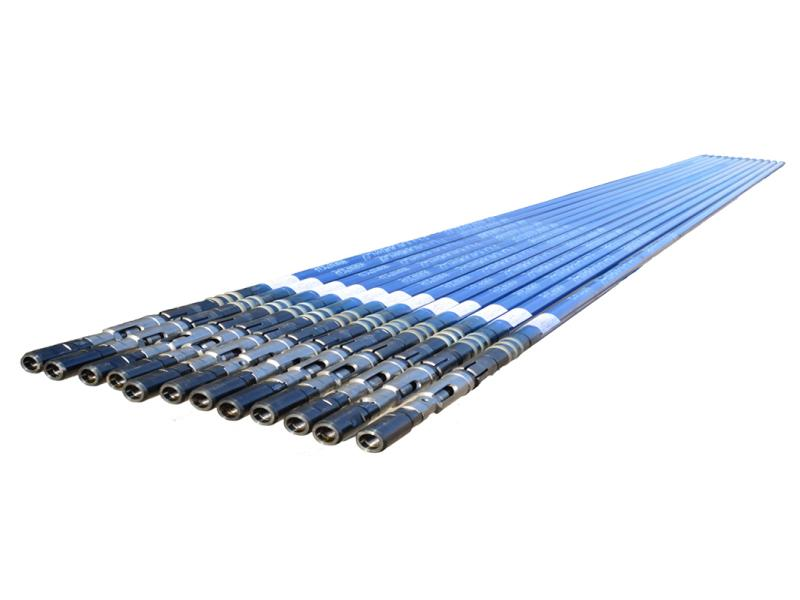

Introduction of forced valve rod pump:

Our forced valve rod pump adopts mechanical opening valve, which makes the opening and closing of the traveling valve faster. Forced valve rod pump can effectively prevent "gas lock" and has the best effect in thermal recovery heavy oil wells. Forced valve rod pump controls the opening and closing of the traveling valve through a rigid connecting rod. The valve action time is <0.1 second, and gas cannot accumulate to form gas lock. Three-stage stroke:

Upstroke: The mechanical valve is forced to close, and the crude oil is sealed and lifted.

Downstroke: The valve body opens instantly, quickly fills the pump cavity, and avoids gas mixing.

Anti-gas lock closed loop: Real-time monitoring of pump cavity pressure, dynamic adjustment of valve opening and closing force, to ensure pure liquid flow suction.

Advantages of pump with forced mechanic valve:

1. The valve body and plunger of mechanical opening valve rod pump are coated with tungsten carbide, which can withstand 400℃ steam erosion. The service life of mechanical opening valve rod pump is twice that of traditional pumps.

2. The mechanical valve assembly of forced valve rod pump supports quick replacement, and the single maintenance time is shortened from 8 hours to 2 hours, and the spare parts commonality rate exceeds 90%.

3. The mechanical valve assembly of mechanical opening valve rod pump has zero delay in valve opening and closing with rigid connecting rod + spring buffer mechanism. The valve seat sealing surface is laser hardened, and the wear resistance life of mechanical opening valve rod pump exceeds 100,000 times.

4.The segmented plunger of mechanical opening valve rod pump (adjustable from 0.6 to 1.2 meters) adopts modular combination design, and the plunger length can be freely increased or decreased according to the well conditions. The surface of mechanical opening valve rod pump will be sprayed with tungsten carbide.

5. Pump with forced mechanic valve has a built-in pressure compensation channel to balance the pressure difference inside and outside the pump cavity and reduce the load on the sucker rod.

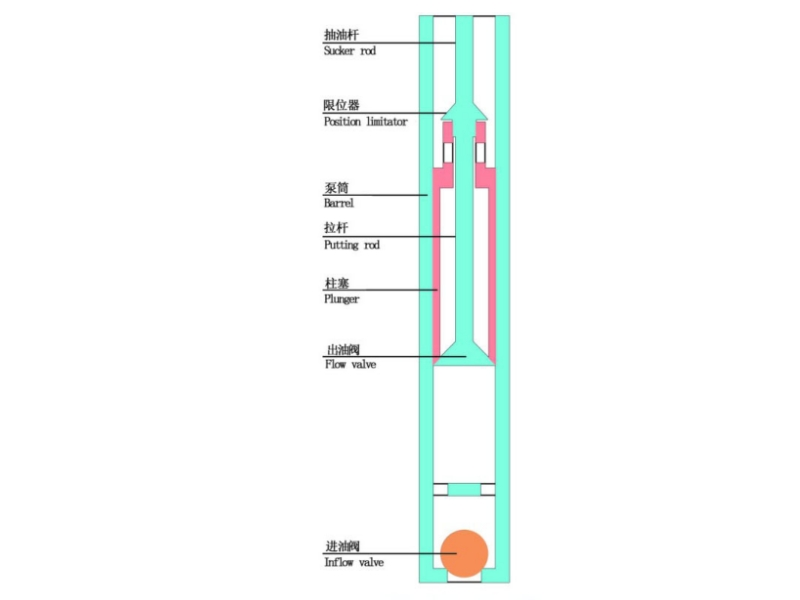

Structural diagram of pump with forced mechanic valve:

The core structure of pump with forced mechanic valve includes:

Sucker rod:

Positian limiter:

Barrel:

Putting rod:

Plunger:

Flow valve:

Inflow valve:

All structures of pump with forced mechanic valve are modularly designed, which is easy to maintain and replace, reducing on-site operation time and operation and maintenance costs.

Technical parameters of anti-gas lock heavy oil rod pump:

Pump bore (mm ) | Length of plunger (m) | Length of barrel (m) | Size of connecting tubing (in ) | Range of stroke (m ) | Pump constant | Size of connecting sucker rod |

| 44 | 0.6~1.2 | 3.0~7.5 | 2 7/8TBG | 2.0~6.0 | 2.23 | CYG19 |

| 57 | 2 7/8TBG | 3.69 | CYG19 | |||

| 70 | 3 TBG | 5.52 | CYG22 | |||

| 83 | 3 1/2TBG | 7.70 | CYG25 |

FAQ of pump with forced mechanic valve:

Q1: Can anti-gas lock heavy oil rod pump be used in oil wells with high sand content?

A: Yes! The tungsten carbide coating on the plunger surface of anti-gas lock heavy oil rod pump has a hardness of HRC70. With the precision filtration structure of the pump barrel, the anti-gas lock heavy oil rod pump can withstand sand content of ≤5%, and the wear rate is 60% lower than that of conventional pumps.

Q2: Is it a waste to use anti-gas lock heavy oil rod pump in low-yield wells?

A: No! The pump diameter and stroke of anti-gas lock heavy oil rod pump can be adjusted in linkage (such as 83mm pump diameter can be adjusted to the minimum stroke of 2.0 meters), and the displacement range is as wide as 50-800m³/d.

Q3: Does the valve type heavy oil recovery sucker rod pump support acidic environment (high H₂S content)?

A: Yes! Valve type heavy oil recovery sucker rod pump can be equipped with duplex stainless steel valve body + polytetrafluoroethylene seal, resistant to H₂S concentration ≤2000ppm, and has passed NACE MR0175 certification.

Q5: Does the replacement of the mechanical valve of the Valve type heavy oil recovery sucker rod pump require the entire pump to be removed?

Answer: No! The valve group of the Valve type heavy oil recovery sucker rod pump adopts a top plug-in design, which can be directly disassembled by the workover rig. A single replacement takes only 2 hours, saving more than 50,000 yuan in operating costs per time.

About us:

Dongsheng products are not only widely used in major domestic oil fields such as Liaohe, Daqing, Changqing, and Shengli, but also exported to the United States, Canada, Romania, Indonesia and other places, winning wide trust and praise from global customers. We will continue to help global oil and energy companies operate efficiently with high-standard products and services, and contribute Chinese wisdom to the development of oil and gas in the world.