Introduction of heavy oil recovery downhole pump:

The floating valve pair of our heavy oil recovery downhole pump adopts a strong opening and closing structure, with a large flow channel area, which is convenient for the exploitation of heavy oil and can prevent gas lock. The fixed valve of the heavy oil recovery downhole pump adopts tungsten carbide alloy material, which improves the timeliness and reliability of the valve pair closing. The working cylinder is added to the outside of the heavy oil recovery downhole pump to prevent the deformation of the pump cylinder during operation and production. It is suitable for deep wells. The heavy oil recovery downhole pump adopts a hanging method, which can automatically adjust the center and reduce the possibility of pump jamming. It has a certain adaptability to inclined wells. The heavy oil recovery downhole pump is suitable for the exploitation of gas wells, inclined wells and deep heavy oil wells (viscosity below 2000Mpa.s).

Advantages of sucker rod pump:

1. The valve in the sucker rod pump adopts a mechanical forced opening and closing structure design. The specially designed guide pin and reinforced spring make the opening and closing no longer rely on a single pressure difference, avoiding the common problem of traditional free valves stopping the pump due to "gas lock" caused by gas entering.

2. The key opening and closing components of the sucker rod pump are made of tungsten-cobalt alloy (hard alloy) and are precision-machined. They are corrosion-resistant and have high impact resistance. The normal operation cycle of the sucker rod pump is extended by more than 3 times, and the maintenance interval is extended from the traditional 3 months to 9-12 months.

3. The sucker rod pump adopts an automatic self-aligning design, a universal joint floating structure is added to the tail end of the pump barrel, and the plunger adaptively adjusts the center position to reduce the probability of eccentric wear and rod breakage, extending the life of the sucker rod pump by 20%-30%, especially in the medium and deep inclined wells and directional wells.

4. The flow channel, valve seat, and valve core of the sucker rod pump are all enlarged (15%-20% higher than conventional pumps), and streamlined transitions and chamfers are used, with less resistance to oil passing. The pumping volume per unit time is increased by 15%-25%.

5. Sucker rod pump can achieve effective pumping at lower power by reducing starting resistance (low pressure difference opening and closing) and optimizing plunger matching accuracy (extremely small leakage), while reducing the mechanical resistance in the up and down strokes of the sucker rod. The energy saving effect can reach 10%-18%, the motor power consumption is lower, the wear of the rod and pipe system is reduced, and frequent maintenance is reduced.

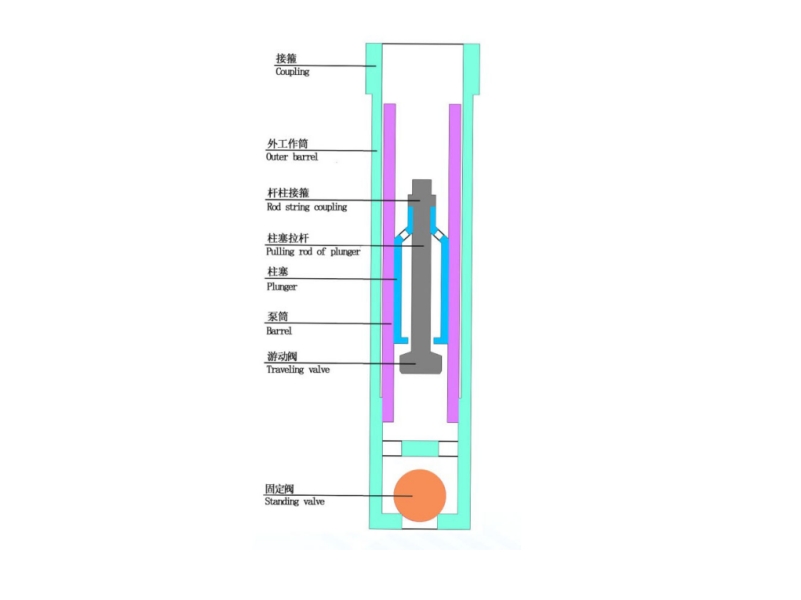

Structural diagram of strong opening and closing sucker oil pump:

The core structure of strong opening and closing sucker oil pump includes:

Coupling:

Outer barrel:

Rod string coupling:

Pulling rod of plunger:

Plunger:

Barrel:

Traveling valve:

Standing valve:

All structures of sucker rod pump are modularly designed, which is convenient for maintenance and replacement, reducing on-site operation time and operation and maintenance costs.

Technical parameters of sucker rod pump:

Pump bore (mm ) | Length of plunger (m) | Length of barrel (m) | Size of connecting tubing (in ) | Range of stroke (m ) | Pump constant | Size of connecting sucker rod | Max outside diameter |

| 44 | 0.6~1.2 | 4.5~7.2 | 2 7/2TBG | 3.0-6.0 | 2.23 | CYG19 | 88.9 |

| 57 | 3 1/2TBG | 3.69 | 108 | ||||

| 70 | 3 1/2TBG | 5.52 | 108 |

FAQ of sucker rod pump:

Q1: What kind of well conditions are suitable for fixed barrel bottom fixed rod pump for deep wells?

A: Sucker rod pump is suitable for special working conditions such as high viscosity heavy oil wells, gas wells, inclined wells, deep wells, etc., especially for wells prone to gas lock and eccentric wear.

Q2: Compared with traditional oil pumps, what are the main advantages of fixed barrel bottom fixed rod pump for deep wells?

A: Fixed barrel bottom fixed rod pump for deep wells solves the problems of gas lock, easy wear, low pump efficiency, etc. of traditional pumps through forced opening and closing, automatic centering, and hard alloy structure. It has a long service life and outstanding energy-saving effect.

Q3: Does your fixed barrel bottom fixed rod pump for deep wells support customized specifications?

A: Yes. Fixed barrel bottom fixed rod pump for deep wells can customize pump diameter, plunger length and other parameters according to customer requirements such as well depth, oil viscosity, stroke, etc., and provide matching pipe design solutions.

About us:

The company has passed ISO9001 quality system certification and American API 11AX certification, and its products strictly follow international standards. We have established a full-process quality control system from raw material input, production and processing to complete machine delivery, and each pump can withstand inspection before leaving the factory. Whether it is a conventional sucker rod pump or a special application pump, it is famous for its high precision and high reliability.