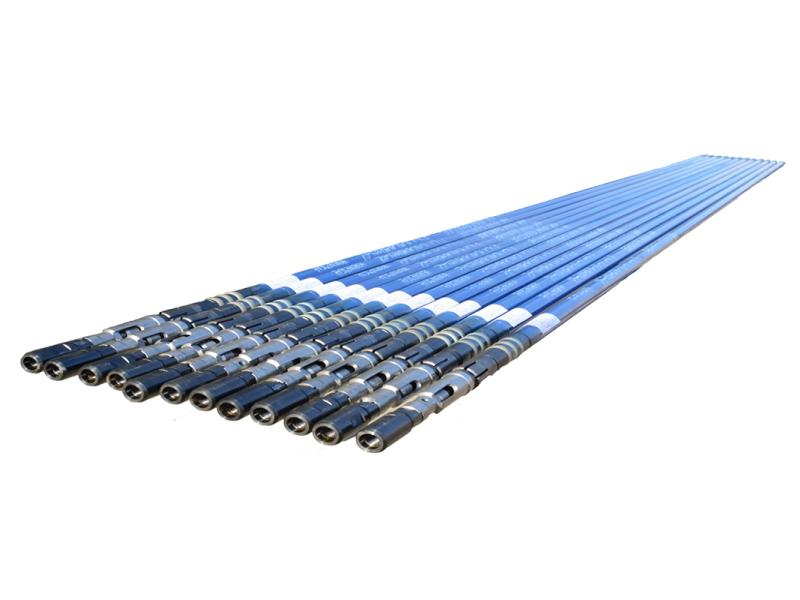

Introduction of Central Exhaust Double Plunger Injection Production Oil Well Pump:

Our company's central exhaust double plunger stainless steel downhole pump has an oil inlet and exhaust groove in the middle of the pump barrel. The groove has the function of oil inlet and exhaust, which can greatly improve the filling coefficient of the pump and prevent gas lock. When using this plunger oil well pumps for double-seal rod pump, the well can be equipped with no oil drainer, and the pipe string can be left unchanged for steam injection thermal recovery. Therefore, this double plunger injection production oil well pump is suitable for gas wells or heavy oil wells. The structural design of our double plunger valve pump has anti-sand and anti-gas lock performance. The double plunger valve pump with medium exhaust can effectively cope with the mining needs under complex working conditions through unique structural optimization.

Features of the Double Plunger Valve Pump with Medium Exhaust:

Our double plunger valve pump is a pump with anti-sand and anti-gas lock functions. The plunger of our double plunger valve pump adopts a separate design, and the pump barrel adopts a three-stage variable diameter series design, which can reduce the risk of solid particles entering the gap between the pump barrel and the plunger, and can achieve the purpose of scraping the inner wall of the pump barrel and self-cleaning of the plunger surface during operation; the strong opening and closing valve design of our stainless steel downhole pump can effectively reduce the downward load in viscous media, and also has the function of anti-gas lock.

Parameter of Double Plunger Valve Pump:

| Pump bore (mm) | Length of plunger (m) | Length of barrel (m) | Range of stroke (m) | Size of connecting tubing ( in ) | Pump constant | Size of connecting sucker rod |

| 44 | 1.2+1.2 | 5.4~8.4 | 1.5~3.0 | 2 7/8 TBG | 2.23 | CYG19 |

| 57 | 3.69 | CYG19 | ||||

| 70 | 5.52 | CYG22 |

Application Scenarios of the Double Plunger Injection Production Oil Well Pump with Medium Exhaust:

1. In the face of oil wells with high oil and gas content, the double plunger stainless steel downhole pump can effectively separate oil and gas through special design to reduce the impact of gas on pump efficiency.

2. The double-piston stainless steel downhole pump with central exhaust is suitable for oil wells that produce high-viscosity crude oil, and plunger oil well pumps for double-seal rod pump can effectively deal with the problem of flow resistance caused by the viscosity of crude oil.

3. In oil wells prone to gas lock, the design of the double-piston anti-gas stainless steel downhole pump can effectively prevent gas from occupying the pump chamber and maintain the normal operation of the pump.

Logistics and Freight:

During the storage, collection, transportation, lifting, placement, use and maintenance of the oil pump, our company ensures that all operations comply with safety regulations and operating procedures. When we transport the pump, we will install it on the bracket and fix it well. The pump rack is placed stably to avoid stacking and fixed to prevent it from falling during transportation. To ensure that the goods you receive are intact, Dongsheng provides you with worry-free after-sales service. The company is committed to establishing the "Dongsheng" image and creating the "Dongsheng" brand. The company adheres to the business philosophy of "customer-centric, creating the greatest value for customers", and is proactive and enterprising to make greater contributions to the oil drilling industry.