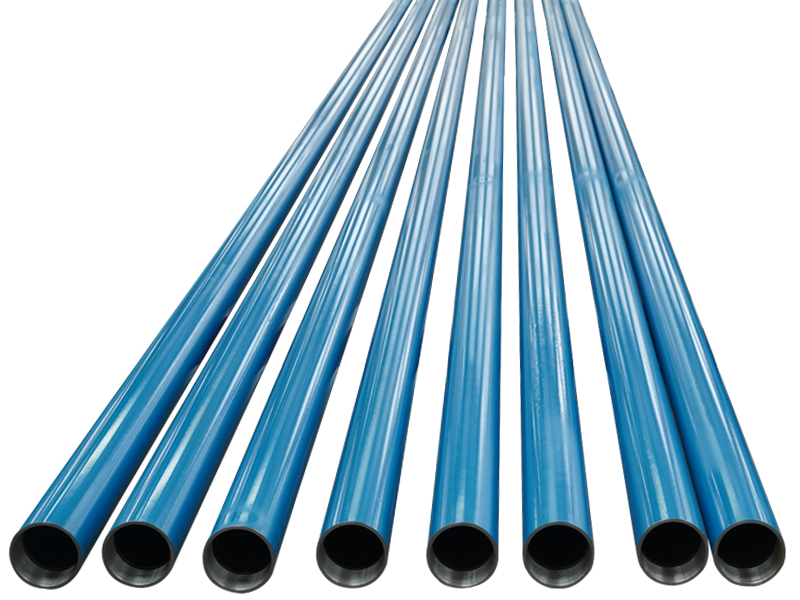

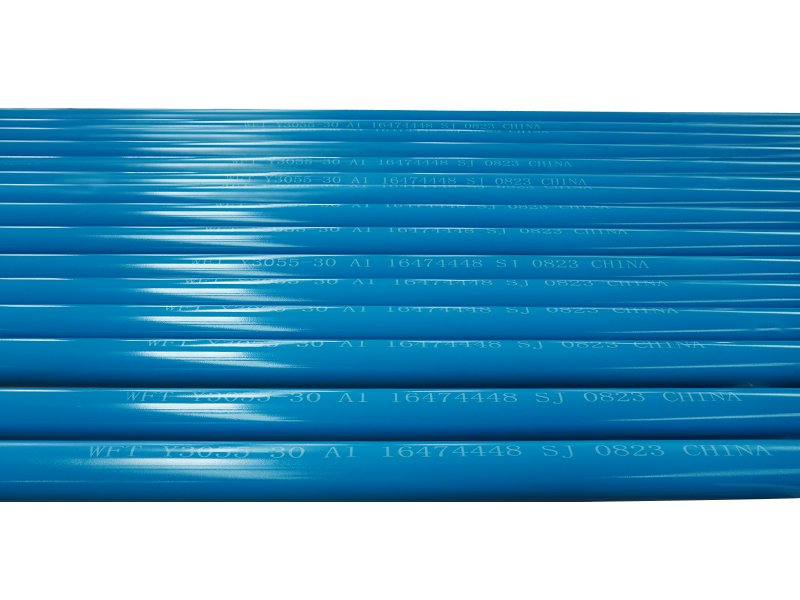

Introduction of Chrome Plating Carbon Steel Barrel:

Hard chrome plating, also known as hard chrome or simply chrome plating, is a thin layer of chrome plated on the substrate to improve its hardness, corrosion resistance and overall performance. Few solutions can match its efficiency in ensuring the service life and reliability of hydraulic cylinders and components. Precision rolling pump barrels are available in a variety of materials, covering brass, stainless steel, low-carbon alloy steel, etc. The dimensional accuracy of precision rolling pump barrels made of soft materials, such as brass and stainless steel, can be ensured by precision rolling processes. The carbon steel chrome-plated rod pump barrels is a rod pump barrels that is plated with a thin layer of chrome on the basis of a low-carbon alloy.

Features of Precision Rolling Pump Barrel:

1. The wear resistance of carbon steel chrome-plated rod pump barrels far exceeds that of ordinary steel pipes, rod pump barrels can extend the service life of the rod pump barrel.

2. The carbon steel chrome-plated rod pump barrels can perfectly match the plunger to reduce the risk of leakage.

3. The chrome plating layer of carbon steel chrome-plated precision rolling pump barrels is dense and non-porous, resistant to corrosion by media such as water, oil, weak acid and alkali, and adaptable to humid environments.

4. The carbon steel base of carbon steel plated rod pump barrels plus the chrome plating process has a lower cost than stainless steel and can meet most medium and high pressure hydraulic scenarios.

Introduction of Precision Rolling Pump Barrel:

The oil pump is one of the equipments used in large quantities in oil field production. The downhole pump barrel is the most important part of the oil pump. As for conventional pumps, the downhole pump barrel accounts for about 60% of the cost of the oil pump. The downhole pump barrel must be processed during production to improve the surface hardness, wear resistance and corrosion resistance of its inner hole. The downhole pump barrel is hard chrome plated: the inner hole of the downhole pump barrel is hard chrome plated to solve the problems of corrosion resistance, wear resistance and hardness, but the chrome plating process causes environmental pollution. In addition, the inner hole needs to be treated with alkali washing and oil removal and acid washing and activation before plating. Because the inner hole is slender and difficult to clean, sometimes it is inevitable that there are unclean places, resulting in insufficient bonding strength between the plating layer and the substrate. During the oil pumping process, the sand in the gap between the plunger and the rod pump barrels is worn and squeezed, causing peeling and pulling, which may cause pump jam accidents in severe cases.

Service Guarantee:

We always adhere to the customer-centric approach and provide a comprehensive service guarantee system to escort you from professional selection guidance to delivery to after-sales service. We can recommend the best solution for you based on your actual working conditions, so that you can buy with confidence and use with ease. We have won the trust of customers with excellent service quality and always provide you with caring, professional and efficient all-round guarantees. From early consultation to later maintenance, our professional team will accompany you throughout the process to give you the best purchasing experience.