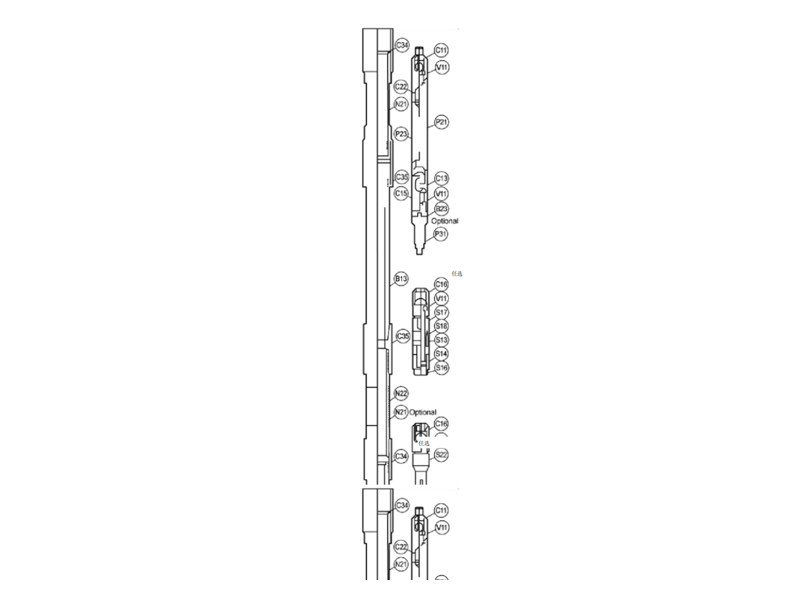

TH tubing pump(tubing rod pumps) introduction:

TH Tubing Pump(tubing rod pumps) is designed to improve the efficiency of underground operations. The plunger surface of tubing rod pumps(TH Tubing Pump) adopts spray-welded nickel-based alloy technology, and the inner wall of the pump barrel of tubing rod pumps(APl Tubing Pump) is treated with hard chrome plating. The key parts of tubing rod pumps(APl Tubing Pump) are made of high-end materials with strong corrosion resistance and excellent mechanical properties. TH Tubing Pump has better corrosion resistance and wear resistance.The structural improvement of tubing rod pumps(APl Tubing Pump) enables the stable operation of tubing rod pumps(APl Tubing Pump) in high temperature, high pressure and corrosive environments. The application of tubing rod pumps(APl Tubing Pump) is widely used in various oil well scenarios, providing a reliable guarantee for oilfield mining.

T represents a tubular pump, and H represents a thick wall.

TH tubing pump(APl Tubing Pump) parameters:

| Standard drawing system specifications | ||||

|

| 2 3/8x1 3/4(60.3x44.5) | 2 7/8x2 1/4(73.0x57.2) | 3 1/2×2 3/4 | 41/2×3 3/4 |

|

| Pump code | |||

|

| 20-175 THC | 25-225 TIC | 30-275 THC | 40-375THC |

symbol | name | Piece number | |||

B23 | Valve cover reducing joint with extractor (optional) | —— | —— | —— | B23-40 |

B13 | Thick-walled pump cylinder | B13-175 | B13-225 | B13-275 | B13-375 |

C11 | Plunger upper open valve cover | C11-20 | C11-25 | C1-30 | C11-40 |

C13 | Column cold group valve cover | C13-175 | C13-225 | C13-275 | C13-375 |

C16 | Fixed valve cover | C16-175 | C16-225 | C16-275 | C16-375 |

C34 | Tubing coupling | C34-20 | C34-25 | C34-30 | C34-40 |

C35 | Pump cylinder coupling | C35-20 | C35-25 | C35-30 | C35-40 |

N12 | Mechanical support joint | —— | —— | —— | N12-40 |

N13 | Support joint | N13-20 | N13-25 | N13-30 |

|

N21 | The upper part is lengthened and short section | N21-20 | N21-25 | N21-30 | N21-40 |

N22 | The lower part is lengthened and short section | N22-20 | V22-25 | N22-30 | N22-40 |

P21 | Integral plunger | P21-175 | P21-225 | P21-275 | P21-375 |

P31 | Fixed valve extractor | P31-175 | P31-225 | P31-275 | P31-375 |

S13 | Support leather bowl seat ring (HR type) | S13-20 | S13-25 | S13-30 | —— |

S14 | Support leather bowl pressure cap (HR type) | S14-20 | S14-25 | S14-30 | —— |

S16 | Support leather bowl coupling | S16-20 | S16-25 | S16-30 | —— |

S17 | Support leather bowl mandrel (HR type) | S17-20 | S17-25 | S17-30 | —— |

S18 | Support leather bowl (HR type) | S18-20 | S18-25 | S18-30 | —— |

V11 | Valve ball and seat |

|

|

|

|

| Swimming valve | V11-175 | V11-225 | V11-250 | V11-375 |

| Fixed valve | V11-175 | V11-225 | V11-250 | V11-375 |

S22 | Mechanical bottom locking support assembly | —— | —— |

| S22-40 |

|

| 20-175 THC abe | 25-225 THC abe | 30-275 THC abc | 40-375 THabce |

| Optional plunger assembly |

|

|

|

|

C15 | Internal thread plunger closed valve cover | C15-175 | C15-225 | C15-275 | C15-375 |

C22 | Internal thread plunger joint | C22-175 | C22-225 | C22-275 | C22-375 |

P23 | Internal thread plunger | P23-175b | P23-225 | P23-275 | P23-375 |

Note: All sizes are in millimeters, and inches are in brackets. | |||||

"The length of the pump barrel is specified in meters (feet), and the standard length is: 0.61m (2ft) to 12.19m (40ft), and the length is incremented by every 0.305m (1ft). Specify the nominal plunger length in meters (feet), and the mating gap is a few hundredths of a millimeter (a few thousandths of an inch). The total length of the lengthened short section is specified in meters (feet), and the standard length is 0.610m (2ft) and 0.914m (3ft). Replacing the P31-375 extractor with the P31-275 extractor is only suitable for pumps with a specification of 4-1/2X3-3/4. When using the B23-40 reducer connector, the P31-275 extractor can be selected. See Annex C for the definition of the symbols of the pump parts. | |||||

TH Tubing Pump(APl Tubing Pump) advantages:

In the oil production process, when there is a problem with the swimming valve pair and the fixed valve pair of the tubing rod pumps(APl Tubing Pump), the tubing rod pumps(APl Tubing Pump) can use the extractor to raise the valve pair through the pumping rod column and plunger, without having to raise the entire tubing rod pumps(APl Tubing Pump) and the oil pipe column together, which reduces the labor intensity of the operation and reduces the operating cost.

FAQ:

Q: What is tubing rod pumps(APl Tubing Pump)?

A: Tubing rod pumps(APl Tubing Pump) is an efficient underground oil recovery device, designed for medium and low-yield wells.

Q: The core advantage of tubing rod pumps(APl Tubing Pump)?

A: Tubing rod pumps(APl Tubing Pump) adopts chrome-plated/tungsten carbide plunger, which has a wear-resistant life of more than 5,000 hours and reduces the frequency of maintenance.

Q: Does APl Tubing Pump support complex well conditions?

A: Tubing rod pumps(APl Tubing Pump) provides alloy steel/stainless steel material and corrosion-resistant coating customization to adapt to high sand content and high mineralization well conditions.

Q: Is the installation restricted?

A: Tubing rod pumps(APl Tubing Pump) supports customization of pump diameters of 38-95mm to match various types of well tube structures.

Q: How to extend the life of tubing rod pumps(APl Tubing Pump)?

A: Regularly monitor the sinking degree to avoid dry grinding; the use of sand-proof screens can improve the operating stability of sucker rod tubing pump.

Customized service:

In the face of complex and changeable oil well conditions, sucker rod tubing pump can tailor an exclusive solution for you:

Material customization: Sucker rod tubing pump provides a variety of material options such as high-strength alloy steel, chrome-plated treatment, stainless steel and carbide coating. Sucker rod tubing pump can accurately meet the wear-resistant and corrosion-resistant challenges of different underground wells.

Coating optimization: According to the characteristics of the well fluid, sucker rod tubing pump can flexibly choose coating or surface strengthening technology to effectively extend the service cycle of sucker rod tubing pump.

Size adaptation: The key parameters such as the diameter of the pump barrel and the length of the plunger of the sucker rod tubing pump can be processed on demand to ensure that the TH tubing Pump is seamlessly matched with the existing well structure or production system.

With in-depth customization capabilities, sucker rod tubing pump is committed to helping customers significantly improve the operating life of equipment under the most demanding well conditions. TH Tubing pump can help you ensure stable and efficient production.

Working principle:

The working principle of TH Tubing Pump is based on the precise cooperation between the pump cylinder and the plunger. The pump cylinder assembly of TH Tubing pump is directly fixed to the end of the tubing column through the tubing coupling, and follows the tubing down to the target production layer. The plunger assembly is connected to the pumping rod column and accurately inserted into the inside of the pump cylinder. When the oil pump drives the plunger to reciprocate up and down:

Upper stroke: The plunger goes up, a negative pressure is formed in the pump cylinder, and the fixed valve is opened to inhale crude oil.;

Down stroke: The plunger squeezes the liquid downwards, and the swimming valve opens to drain the oil to the tubing.

The key to TH Tubing pump lies in the high-precision dynamic sealing between the plunger and the pump cylinder to ensure efficient liquid extraction in each stroke. The structure of this TH tubing pump eliminates the need for separate pumping operations and significantly reduces the failure rate. The wear-resistant design of TH Tubing pump is especially suitable for sand-containing well conditions, and the modular characteristics of TH Tubing pump can improve maintenance efficiency.TH Tubing Pump achieves long-term stable oil recovery through precise gap control.

About us:

Tieling Dongsheng Petroleum Machinery Co., Ltd. has passed the ISO 9001 quality management system certification and obtained the API11AX certificate for use.The company covers 100 kinds of pumping rod pump products and accessories such as underground TH tubing pump, long plunger sand pump, drainage pump, centralizer, spraying metal plunger, alignment and uniform grinding. The company has established a complete inspection system, and implements the whole process control and inspection from raw materials, semi-finished products to finished products.