Product introduction:

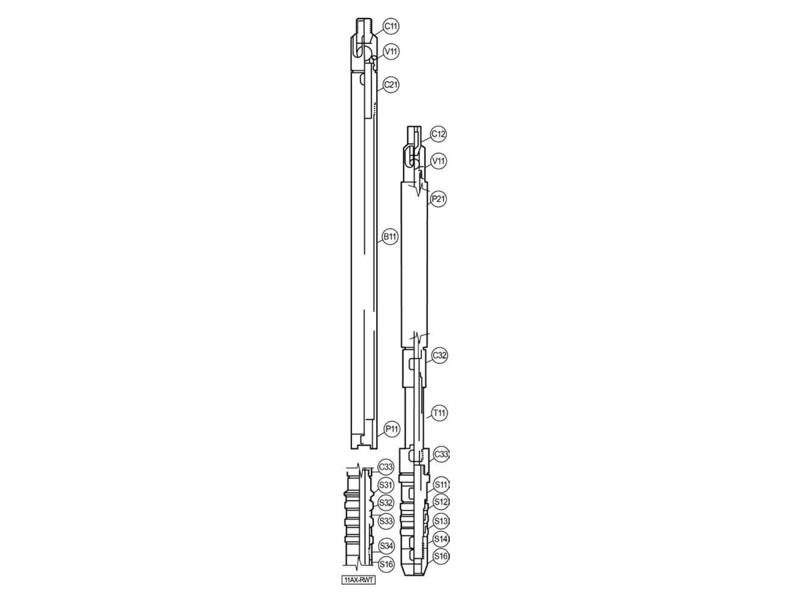

With its good strength and large-caliber design, large oilfield tubing pump has become an ideal choice for large-scale production wells. This large oilfield tubing pump is particularly suitable for mining high-viscosity crude oil, and its increased fluid flow area can effectively increase production. The vertical valve of large oilfield tubing pump is designed as a fixed and non-extractable structure, making underground operation stable and reliable. During installation, the pump cylinder assembly of large oilfield tubing pump is directly connected to the end of the oil pipe column down to the bottom of the well; The plunger assembly is connected to the pumping rod column and goes down into the pump cylinder. Through the sucker rod, the plunger is driven to reciprocate up and down in the pump cylinder, and the crude oil lifting production process can be efficiently realized. Choosing large oilfield tubing pump is precisely the guarantee of high production capacity and high reliability.

Product advantage:

As an efficient oil production equipment, large oilfield tubing pump is made of high-strength alloy material, which has excellent wear resistance and corrosion resistance, which can greatly extend the service life of large oilfield tubing pump. The API 11AX sucker rod pump is manufactured in strict accordance with the API 11AX standard, with excellent sealing performance, effectively reducing leakage and improving oil recovery efficiency. Compared with the ordinary API 11AX sucker rod pump, the plunger and bushing of this API 11AX sucker rod pump have higher accuracy, more stable operation, and lower maintenance frequency. Whether it is under high pressure or high sand content conditions, this API 11AX sucker rod pump can work reliably and provide a strong guarantee for oilfield production. It is the preferred API 11AX sucker rod pump equipment for many oil fields.

Structural design features:

The structural design of API 11AX sucker rod pump is very advantageous. The plunger of API 11AX sucker rod pump adopts a special surface treatment process to reduce friction loss and improve the operating efficiency of tubing pump for oil fields. The fixed valve and swimming valve of tubing pump for oil fields adopt a double valve ball design to enhance the sealing effect, reduce the risk of leakage, and ensure the oil recovery efficiency of tubing pump for oil fields.The inner wall of the pump cylinder of tubing pump for oil fields has high accuracy and closely cooperates with the plunger to reduce gap leakage and improve the overall performance of tubing pump for oil fields. In addition, the connecting parts of the tubing pump for oil fields are designed with high-strength threads to enhance the stability of the connection, avoid falling off underground, and ensure the safe operation of the tubing pump for oil fields. The reasonable structural design makes this tubing pump for oil fields have better performance and stronger reliability.

Specifications of large oilfield tubing pump:

| Model specifications | Plunger length (m) | Pump barrel length (m) |

| API 11AX-28 | 0.6-1.2 | 1.5-2.1 |

| API 11AX-56 | 0.9-1.5 | 2.1-3.0 |

| API 11AX-83 | 1.2-2.0 | 2.5-3.5 |

| API 11AX-108 | 1.5-2.5 | 3.0-4.0 |

Logistics and transportation:

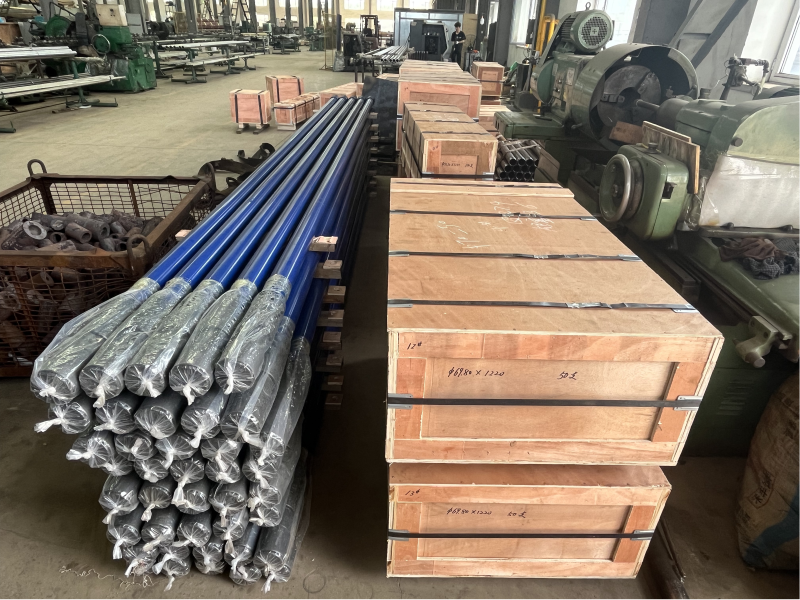

To ensure the delivery of petroleum machinery and equipment, the company has established professional logistics management personnel. For domestic customers, the company uses a complete road transportation system and has established strategic cooperation with a number of high-quality logistics companies to ensure that products are delivered to major oil fields in a short time. For international orders, the company uses multi-channel transportation methods such as sea and air transportation, and equips customers with professional teams to shorten cross-border transportation time and ensure the quality of the goods received.

Product certificate:

Service guarantee:

In the petroleum machinery industry, the stable operation of equipment is crucial. Our company has established a service mechanism to actively respond to customer problems, formulate corresponding solutions for customer problems, adhere to customer experience as the core, and ensure that customers can get problems solved as soon as possible.

About us:

Tieling Dongsheng Petroleum Machinery Co., Ltd. has been certified by ISO 9001 Quality Management System, and licensed to use API11AX certificate. The company covers 100 kinds of Sucker Rod Pump products and Accessories such as subsurface tubing pump, long-plunger anti-sand pump, drain, centralizer, spray metal plunger,alignment and unified grinding, etc. The company has established a complete inspection system and apply entire-process-control and inspection, from raw materials, semi-finished products to finished product.