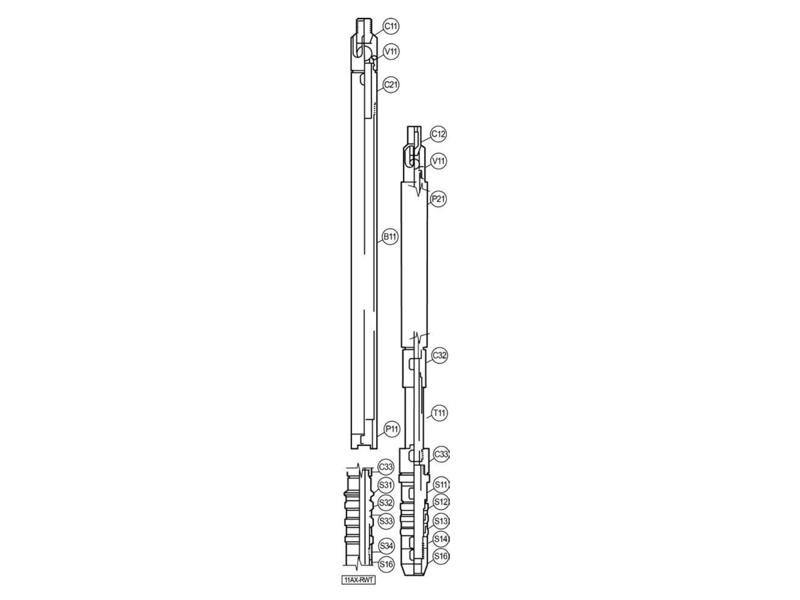

Product introduction:

Dongsheng API standard pump is an efficient oil production equipment. This API standard pump is made of military-grade alloy material. The fatigue strength is 30% higher than that of ordinary API standard pump, and it can operate stably in a high-pressure environment. This API standard pump is produced strictly in accordance with the API 11AX standard. The sealing components adopt a dual leak-proof design, and the leakage is much lower than the industry average, which makes the oil recovery efficiency of API standard pump significantly improved. Compared with the traditional subsurface rod pump, the life of the wearing parts of the subsurface rod pump is extended by 50%, the number of downtime and maintenance is reduced, and the operating cost of the oilfield is reduced. Whether it is heavy oil or high-gas well conditions, this subsurface rod pump can maintain efficient operation and is the preferred subsurface rod pump equipment for oil fields to increase production.

Applicable scenarios:

Subsurface rod pump has a wide range of application scenarios. In conventional oil fields on land, subsurface rod pump can stably extract crude oil to ensure continuous production; on offshore platforms, subsurface rod pump's anti-salt spray design can resist seawater erosion and extend the service life of subsurface rod pump.For deep and ultra-deep wells, the high-strength structure of the subsurface rod pump can withstand kilometers of downhole pressure and operate stably; in high-sand oil wells, the wear-resistant coating of the subsurface rod pump can reduce sand wear and reduce the failure rate.Whether it is a heavy oil well or a low-permeability reservoir, this subsurface rod pump can work efficiently and is a highly adaptable API standard pump equipment.

Installation operation method:

The first step: Check the parts of the API standard pump to ensure that there is no damage, and ensure the installation foundation of the downhole sucker rod pump.

The second step: Clean the connecting surface of the downhole sucker rod pump to remove impurities and avoid the API standard pump from being tightly sealed.

The third step: Tighten the downhole sucker rod pump cylinder and the tubing according to the prescribed torque to ensure that the downhole sucker rod pump connection is stable.

The fourth step: Apply special grease to the downhole sucker rod pump plunger to reduce installation wear.

Step 5: Slowly release the downhole sucker rod pump to avoid collisions and protect the downhole sucker rod pump parts.

Step 6: Trial operation check, confirm that the downhole sucker rod pump is running normally, and complete the installation of the downhole sucker rod pump.

Qualification certification:

Service guarantee:

Our company's service is not limited to the sales link, but throughout the entire use cycle of the product. Our company will regularly visit the equipment operation and provide maintenance suggestions. "Satisfy every customer" is the service tenet of Dongsheng Petroleum Machinery. The company continuously optimizes the service process by regularly surveying customer satisfaction and establishing a service evaluation system. Our company has a complete delivery quality system, which is fully controllable from production off the line to customer site, ensuring that every equipment can be delivered to customers safely and on time. Our logistics team is ready to provide you with professional delivery solutions at any time.

FAQ:

Q1:Are you a Factory or a Trader?

A1:We are the manufacturer. As a leading pump manufacturer in China, it is committed to designing, developing, manufacturing and supplying oilfield products, such as sucker rod pumps, special sucker rod pumps and downhole tools, etc.

Q2:Do you Have a Quality Control System?

A2:Yes, we are ISO 9001 quality management system certified and licensed to use API 11AX certificate.

Q3:Can we Provide Customized Service?

A3:Yes, we can customize it according to your needs.Make sure every piece of equipment is exactly what you need to work in your oilfield.

Q4:What can you Buy from us?

A4:The company covers 100 kinds of rod pump products and accessories, such as downhole tubing pumps, long plunger sand control pumps, drains, centralizers, metal spray plungers, alignment, and unified grinding.

Q5:How about the Production and Delivery Time?

A5:The production time mainly depends on the product and quantity. After you place an order, we will produce as soon as possible. The delivery time depends on your country and port.

About us:

Tieling Dongsheng Petroleum Machinery Co., Ltd. was established in 2000. As a leading pump manufacturer in China, it is committed to design, develop, manufacture and supply oilfield products such as sucker rod pump, special sucker rod pump and downhole tools, etc. The company is the qualified material supplier of CNPC , Sinopec and Weatherford. It covers an area of more than 20,000 square meters, 96 existing staffs, including 20 engineers and technicians.Registered capital of 56 million yuan.Annually produce more than 20,000 oil pumps and special oil pumps.