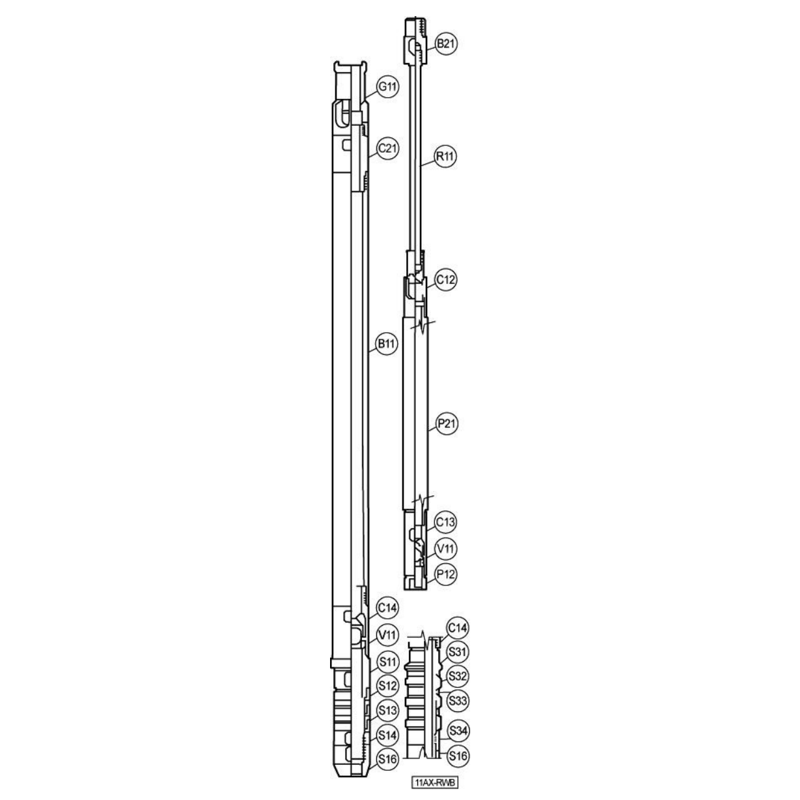

Sucker rod pump introduction:

RWB API insert pumps are fixed-cylinder bottom fixed-rod RWB API insert pumps. The pump barrel is designed with thin walls and is adapted to a specific size tubing through an internal threaded connection, allowing RWB API insert pumps to make efficient use of tubing space. This RWB API insert pumps can work stably in an oil well of about 10,000 feet, and the fixed bottom design can balance the pressure to ensure the stable operation of RWB API insert pumps. RWB API insert pumps provide mechanical and cup-type seating methods, and components can also be installed to deal with mining problems. With the bottom discharge valve, RWB API insert pumps can further ensure the long-term reliable operation of RWB API insert pumps.

Model meaning:

R: Stands for Rod pump .

W: Means a stationary barrel.

B: It means that the bottom is fixed (Bottom Hold-Down).

Advantages of RWB API insert pumps:

RWB API insert pumps has outstanding advantages and can provide strong support for oilfield production. This API 11AX RWB insert rod pump is suitable for a variety of working conditions. Whether it is a low-sand well, a low-level well, or a medium- and shallow-depth oil well, the API 11AX RWB insert rod pump can work stably without frequent adjustments, which greatly reduces the difficulty of oilfield operations.In terms of oil recovery efficiency, API 11AX RWB insert rod pump adopts a high-flow design, with a large inner diameter pump cylinder, low crude oil flow resistance and fast extraction speed, allowing API 11AX RWB insert rod pump to efficiently complete crude oil extraction and increase single-well production.

From the point of view of durability, the fixed structure at the bottom of the API 11AX RWB insert rod pump can balance the pressure, reduce the impact of reservoir pressure on the API 11AX RWB insert rod pump, and reduce component wear; The internal connection design also reduces the point of failure and extends the service life of the API 11AX RWB insert rod pump. Moreover, the API 11AX RWB insert rod pump can be equipped with special components to easily deal with problems such as sand blocking and air disturbance, further broadening the scope of application of the API 11AX RWB insert rod pump. In addition, insert rod pump complies with API standards, the quality is guaranteed, and there is no need to worry about unstable performance when using it.

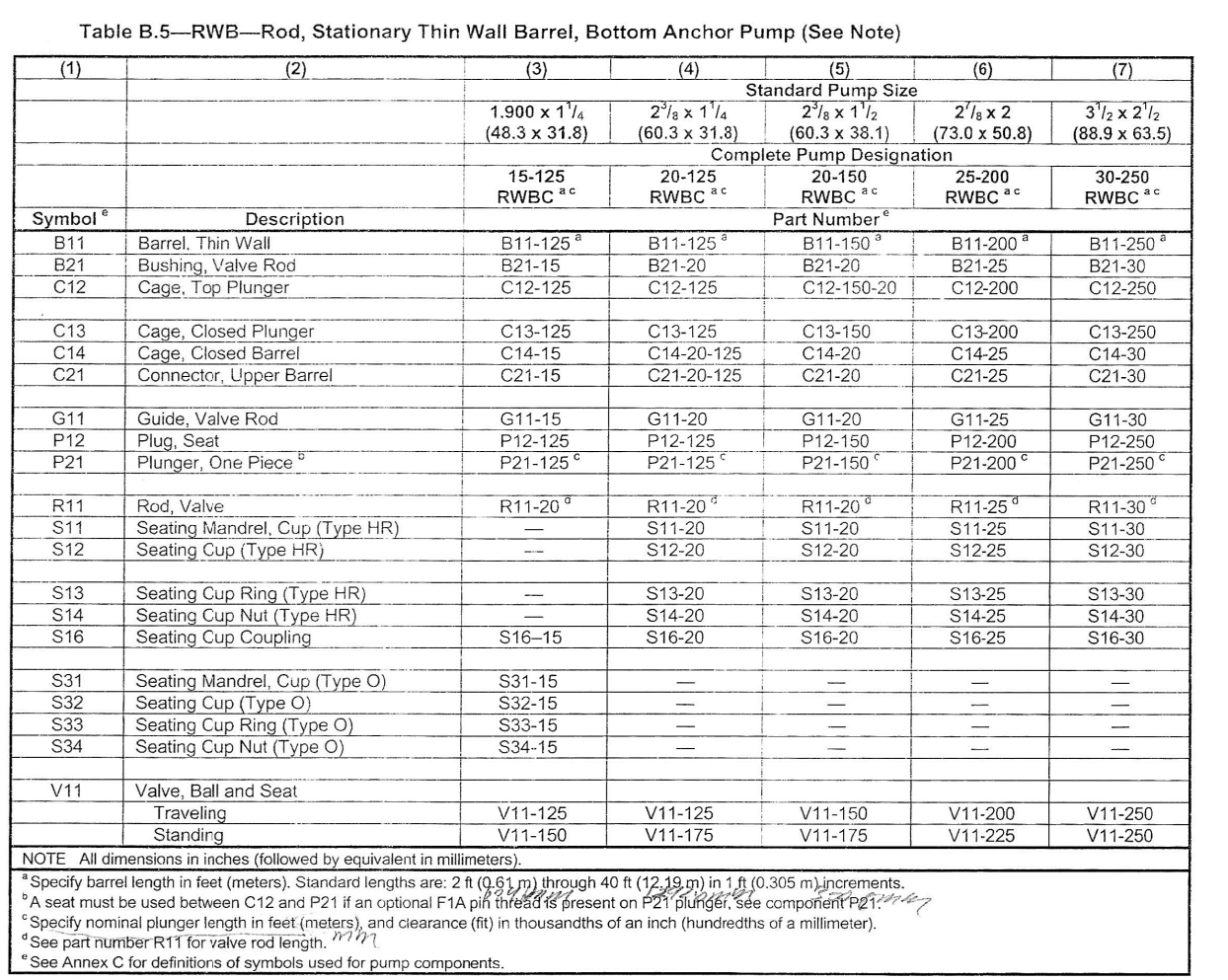

Sucker rod pump specifications:

Applicable scenarios:

RWB insert rod pump is widely used in onshore oil fields, shallow sea oil fields and other scenarios, especially suitable for the following situations:

Oil well mining at medium and shallow depths (1000-3000 meters);

Oil wells with sand content ≤5% and no corrosive media;

Oil fields that require high oil recovery efficiency and require long-term continuous production.

How sucker rod pump works:

The working principle of sucker rod pump revolves around “reciprocating motion + one-way valve control”. The core is to rely on the sucker rod to drive the plunger in the insert rod pump to move up and down to achieve crude oil extraction.When the sucker rod pulls the plunger upward, the pressure in the pump cylinder of the insert rod pump decreases, the bottom fixed valve is opened, and the crude oil is sucked into the insert rod pump; when the plunger is moved down, the pressure in the sucker rod pump increases, the fixed valve is closed, the swimming valve is opened, and the crude oil is pushed into the tubing. In this process, the fixed-cylinder design of sucker rod pump allows the pump cylinder to be fixed in the tubing to ensure the stable movement of the plunger; The fixed structure at the bottom of sucker rod pump balances the pressure and avoids affecting the inhalation and discharge of crude oil. It is through this cycle that sucker rod pump continues to transport crude oil from underground to the ground. Every time it goes back and forth, the valves of sucker rod pump are precisely matched, so that the crude oil does not return, so that sucker rod pump can efficiently and stably complete oil production operations to meet the daily mining needs of oil fields.

About us:

Tieling Dongsheng Petroleum Machinery Co., Ltd. has been certified by ISO 9001 Quality Management System, and licensed to use API11AX certificate. The company covers 100 kinds of Sucker Rod Pump products and Accessories such as subsurface tubing pump, long-plunger anti-sand pump, drain, centralizer, spray metal plunger,alignment and unified grinding, etc. The company has established a complete inspection system and apply entire-process-control and inspection, from raw materials, semi-finished products to finished product. The company is committed to set "Dongsheng" image and create "Dongsheng" brand. Focus on the customer and delivery the maximum value for customers as the management concept, positive enterprising to make a greater contribution to the petroleum drilling.