Introduction of RXB API insert pump:

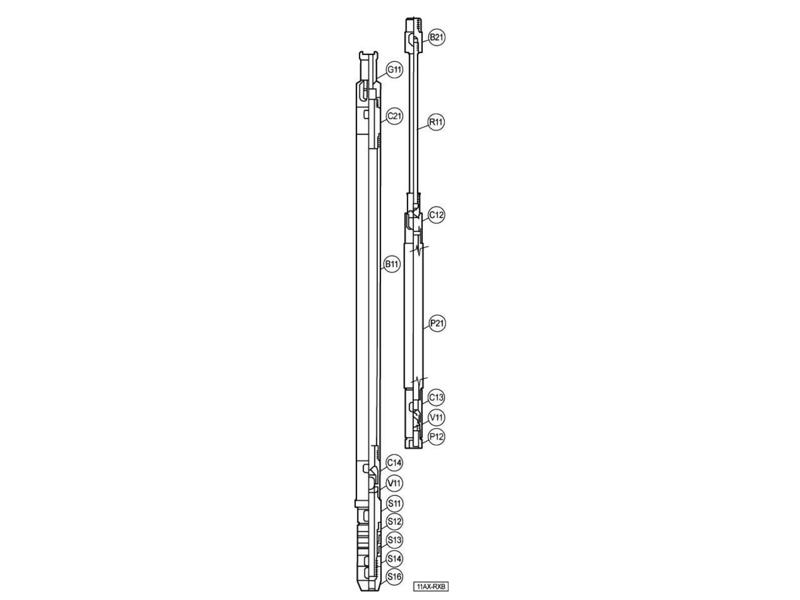

The core component of RXB RXB API insert pump, RXB API insert pump, adopts API standard design. This RXB API insert pump achieves a larger diameter through the improvement of the inner wall thread and improves the efficiency of media delivery. This RXB API insert pump is equipped with a thick walled pump barrel and a hard chrome plated plunger, which enables sucker rod pump to maintain stable operation in low sand wells. The unique bottom fixed structure allows sucker rod pump to balance the internal and external pressure and avoid the wear problems caused by pressure fluctuations of conventional sucker rod pump. Whether it is low-viscosity crude oil or granular media, this sucker rod pump can continue to operate with corrosion and wear resistance, giving full play to the adaptability advantages of sucker rod pump in complex well conditions.

Model meaning:

RXB is the code name of the API standard plug in sucker rod pump series:

R :stands for Rod Pump.

X :represents Extra performance.

B :refers to Bottom Hold-down.

Advantages of sucker rod pump:

1.This sucker rod pump adopts a large-diameter flow channel design. Compared with ordinary sucker rod pump, the liquid overcurrent area is significantly increased, which can effectively reduce the risk of clogging, so that sucker rod pump can maintain efficient oil recovery in high-sand wells, and the average daily oil production of a single well is significantly higher than that of traditional sucker rod pump.

2. The pump barrel of API 11AX rod pump (RXB Insert Rod Pump) is made of high-strength alloy steel, the inner wall is treated with multiple layers of wear-resistant coating, and the hardness is at a high level. With high-precision sealed plunger, the wear rate of insert rod pump is greatly reduced, and the replacement cycle of insert rod pump is significantly extended, so that the average service life of API 11AX rod pump is greatly extended.

3. This API 11AX rod pump supports a wide range of temperature operating environments, and at the same time, through a special pressure balance structure, the insert rod pump can adapt to a variety of wellhead pressure scenarios, whether it is a low-temperature shallow well or a high-temperature deep well, this insert rod pump can operate stably, solving the problem that ordinary insert rod pumps are prone to failure under complex operating conditions.

4. The core components of RXB insert rod pump are modular in design, and there is no need to use special tools during disassembly and assembly. Compared with the traditional RXB insert rod pump, the maintenance time is greatly shortened. At the same time, the wearing parts of RXB insert rod pump are more versatile and the cost is lower when purchasing, which further reduces the cost of using the whole life cycle of RXB insert rod pump.

Packaging and transportation:

For precision petroleum equipment such as RXB insert rod pump, we adopt a customized packaging scheme: the outer layer uses high-strength corrugated boxes with wooden pallets, and the inner layer is wrapped in pearl cotton cushions and moisture-proof film, which effectively isolates collisions, moisture and dust during transportation, making RXB insert rod pump (API 11AX Rod Pump) intact from the production workshop to the customer site. At the same time, we have established long-term cooperation with a number of professional logistics companies. We can choose transportation methods such as road, rail or sea transportation according to the customer's location, and are equipped with a real time logistics tracking system, allowing you to keep abreast of RXB insert rod pump transportation dynamics and achieve accurate delivery.

Certificate:

Supply capacity:

As an enterprise deeply engaged in the field of petroleum equipment, the company has a standardized production workshop and a mature supply chain system. It can flexibly adjust the production plan according to the scale of customer orders to ensure that API 11AX rod pump is delivered on time and in sufficient quantities. Whether it is the bulk purchase of conventional API 11AX rod pump or the demand for customized API 11AX rod pump under special working conditions, the company can rely on sufficient raw material reserves and efficient production processes to ensure the stability of supply and avoid equipment shortages affecting customer operation progress.

About us:

The company has established a perfect after-sales service system to provide customers with full-process support from API 11AX rod pump installation guidance to daily maintenance: The professional technical team can assist customers in completing the installation and commissioning of API 11AX rod pump through online remote guidance; For problems that arise during the use of API 11AX rod pump, after-sales personnel will respond within 24 hours and provide timely troubleshooting and maintenance plans.