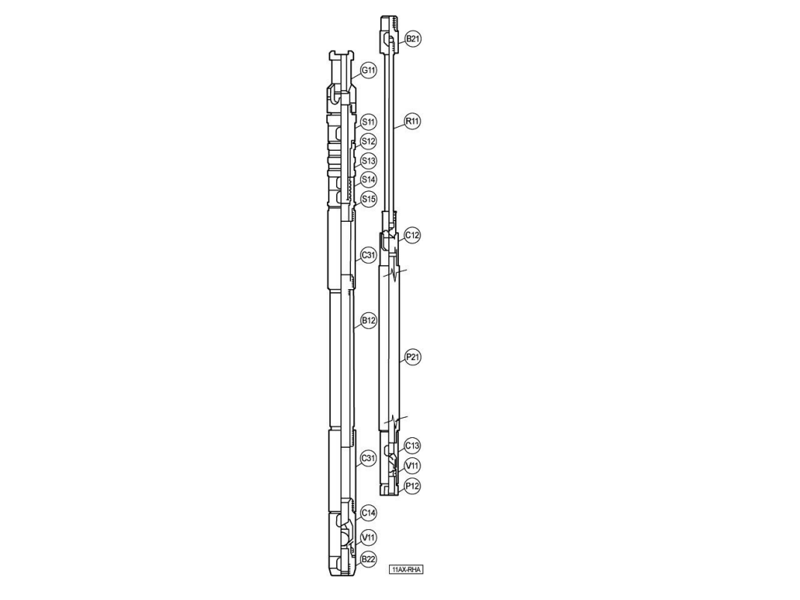

RHA Insert Rod Pump Introduction:

Our RHA insert rod pump is a common mechanical oil production pump used in oil wells. Installed within the tubing string of an oil well, RHA insert rod pump primarily relies on the up-and-down motion of the sucker rod to drive the plunger, thereby lifting well fluid. The performance and technical requirements of our RHA insert rod pumps comply with API standards and GB/T18607-2008.

RHA Insert Rod Pump Model Explanation:

R → Rod Pump.

H → Heavy Wall Barrel, suitable for highly abrasive and high-pressure well conditions.

A → Top Anchor, meaning the pump is secured to the tubing via its top anchor.

Thus, the RHA is an insert pump for oil wellsp consisting of a fixed barrel, a thick-walled pump barrel, and a top anchor.

Downhole Rod Pump Parameters:

| Downhole rod pump specifications | |||||

| 2 3/8x1 1/4 (60.3x31.8) | 2 7/8X1 1/2 (73.0X38.1) | 2 7/8x1 3/4 (73.0X44.5) | 3 1/2X2 1/4 (88.9x57.2) | ||

| Downhole rod pump code | |||||

| 20-125 RHACabc | 25-150 RHACabc | 25-175 RHACabc | 30-225 RHACabc | ||

| Symbol | Name | Part number of RHA insert rod pump | |||

| B12 | Thick-walled pump cylinder | B12-125a | B12-150a | B12-175a | B12-225a |

| B21 | Valve stem reducer | B21-20 | B21-25 | B21-25 | B21-30 |

| B22 | Pump cylinder valve housing reducer | B22-20 | B22-25 | B22-25 | B22-30 |

| C12 | Plug upper valve housing | C12-125 | C12-150-25 | C12-175 | C12-225 |

| C13 | Externally threaded plunger closed valve housing | C13-125 | C13-150 | C13-175 | C13-225 |

| C14 | Pump cylinder closed valve housing | C14-20 | C14-25 | C14-25 | C14-30 |

| C31 | Extension junction box | C31-125c | C31-150c | C31-175c | C31-225c |

| G11 | Valve stem guide sleeve | G11-20 | G11-25 | G11-25 | G11-30 |

| P12 | Valve seat pipe plug | P12-125 | P12-150 | P12-175 | P12-225 |

| P21 | Integral column | P21-125b | P21-150b | P21-175b | P21-225b |

| R11 | Valve stem | R11-20e | R11-25e | R11-25e | R11-30e |

| S11 | Support cup mandrel (type HR) | S11-20 | S11-25 | S11-25 | S11-30 |

| S12 | Support cup (type HR) | S12-20 | S12-25 | S12-25 | S12-30 |

| S13 | Support cup seat ring (type HR) | S13-20 | S13-25 | S13-25 | S13-30 |

| S14 | Support cup pressure cap (type HR) | S14-20 | S14-25 | S14-25 | S14-30 |

| S15 | Support cup reducer | S15-20 | S15-25 | S15-25 | S15-30 |

| VII | Valve ball and seat | ||||

| Floating valve | V11-125 | V11-150 | V11-175 | V11-225 | |

| Stationary valve | V11-175 | V11-225 | V11-225 | V11-25 | |

| NOTE: All dimensions for API insert pumps are in millimeters with inches in parentheses.

Specifies pump barrel length in meters (feet). Standard lengths are from 0.61m (2ft) to 12.19m (40ft), with length increments of 0.305m (1ft).

Specifies nominal plunger length in meters (feet). Fit tolerances are in hundredths of a millimeter (thousandths of an inch).

Specifies total extension coupling length in thousandths of a meter (full foot). Standard lengths are in increments of 0.152m (1/2 ft).

If the male threaded connection for plunger P21 is FIA, a valve seat must be installed between C12 and P21. Refer to part P21.

Refer to part R11 for valve stem components. | |||||

The above are detailed specifications for the RHA API insert pump.

We also offer other API insert pump models:

RHB API Insert Pump

RWA API Insert Pump

RWB API Insert Pump

RWT API Insert Pump

RXB API Insert Pump

Downhole Rod Pump Service and Supply Capabilities:

One-Stop Service of API Insert Pump:

We not only provide a complete RHA plug-in downhole rod pump, but also offer a full suite of spare parts. Core components such as the valve ball, valve seat, plunger, and pump barrel can be replaced individually, helping customers reduce maintenance costs, minimize well downtime, and ensure continuous and stable well production.

Customized Services of RHA Insert rod pump:

Oil well operating conditions vary significantly, so we offer a variety of customized options based on customer needs:

Downhole rod pump material options: High-strength alloy steel, chrome plating, stainless steel, carbide coating, etc., to meet varying wear and corrosion resistance requirements;

Downhole rod pump coating processes: Coatings or surface enhancement technologies are selected based on well fluid characteristics to extend pump life;

Downhole rod pump dimensions: The pump barrel of downhole rod pump diameter and plunger length can be customized to customer specifications to ensure a perfect fit with existing wellbore or production system.

Through customized solutions, we help customers extend the operating life of downhole rod pumps in complex well conditions.

Delivery Guarantee of Downhole Rod Pump:

We maintain ample inventory of insert pump for oil wells and can flexibly arrange delivery based on order requirements.

Adequate Inventory: Common specifications of insert pump for oil wells and spare parts are always in stock to meet urgent needs.

Technical Services of Insert Pump for Oil Wells:

Installation Guide: We provide detailed illustrated manuals and remote video tutorials for insert pump for oil wells to help customers quickly get started.

Maintenance Guide: We share daily maintenance methods and common troubleshooting tips for insert pumps for oil wells.

Remote guidance: The engineering team can provide customers with real-time insert pump for oil wells technical answers via phone, email, and video conferencing;

Training: We offer customized technical training to enhance the skills of our on-site operators.

We not only sell insert pump for oil wells, but also provide long-term, reliable service to help customers reduce operational risks and improve overall oil production efficiency.

FAQ of API Insert Pump:

Q: What are the main differences between the RHA insert rod pump and the RWA API insert pump?

A: The RHA insert rod pump has a thick-walled barrel, capable of withstanding higher pressures and suitable for medium-depth wells and wells containing sand. The RWA API insert pump has a thin-walled barrel and is primarily used in shallow wells.

Q: How should I choose a base for my downhole rod pump?

A: Mechanical bases are suitable for high-temperature environments and require less frequent maintenance. Cup-type bases are easy to install but require replacement each time the pump is disassembled.

Q: Can the material of our insert pump for oil wells be customized?

A: Yes, we offer custom insert pump for oil wells with chrome plating, carbide coating, and special alloy steel options to suit different well conditions.

About Us:

Dongsheng specializes in the research, development, production, and sales of API Insert Pumps and related accessories. We are committed to providing high-quality, standard-compliant API Insert Pumps and solutions to the global oil and gas industry. Leveraging advanced manufacturing processes, strict quality control, and comprehensive after-sales service, our API Insert Pumps are exported to numerous oil and gas markets, including the Middle East, South America, North America, and Southeast Asia.

We have established long-term partnerships with several globally renowned energy and engineering companies, including:

CSSC、SLB、Weatherford、Sinopec、CNPC.

These clients represent key players in the global oil and energy industry. Their recognition not only reflects the quality of our downhole rod pumps but also demonstrates our reliability and competitiveness in the international market.

We will continue to uphold the principle of "Quality First, Service Foremost" to provide our global customers with superior RHA Insert Rod Pumps and professional services, striving to become your trusted long-term partner.

Contact Us:

Get a Quote or Technical Data

Fill out the form to share your well requirements and we will respond within 24 hours.