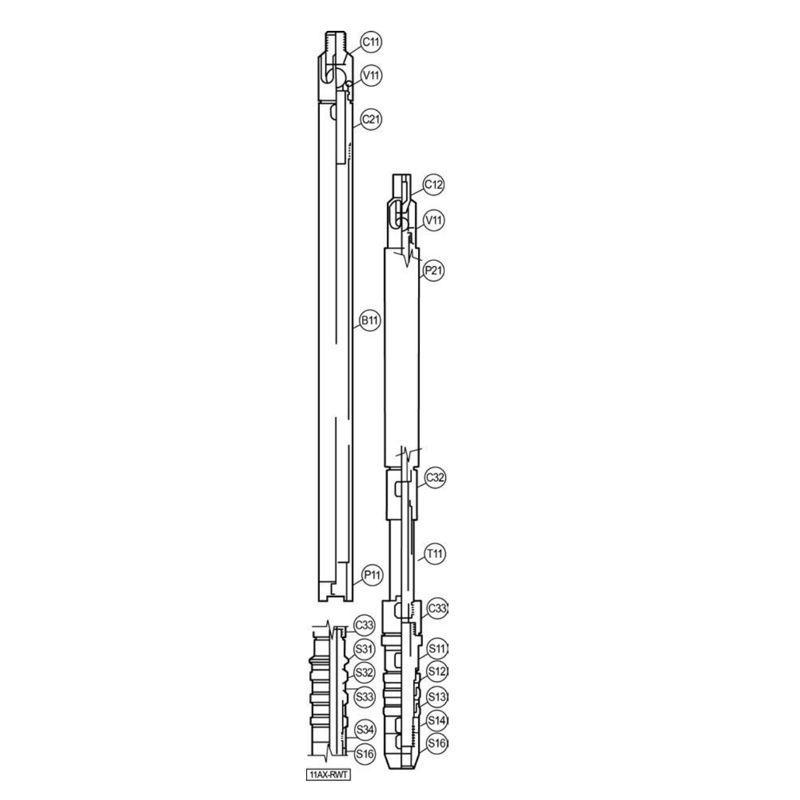

Introduction of RWT API insert pumps:

As a professional sucker rod pump, RWT insert rod pump plays a key role in oil production operations.When working, RWT insert rod pump relies on the sucker rod to drive the pump cylinder up and down to achieve liquid extraction. When the pump cylinder goes up, the volume of the pump chamber increases, the pressure decreases, and the liquid enters the pump chamber through the suction valve; when the pump cylinder goes down, the volume of the pump chamber decreases, the pressure increases, and the liquid is pressed into the tubing through the discharge valve. Throughout the workflow, RWT insert rod pump continuously and stably pumps underground liquid to the ground. RWT insert rod pump has a reasonable structural design and can effectively cope with complex underground environments. Whether it is an ordinary oil well or a special oil well with certain corrosive properties and high sand content, RWT insert rod pump can rely on its own advantages to ensure efficient oil production operations.

Model meaning:

R: Represents a rod pump.

W: Indicates that the pump cylinder is designed with thin walls.

T: It shows that the pump is a fixed bottom structure of the moving cylinder type, which clarifies the fixing method and working characteristics of the pump underground.

Advantages of RWT insert rod pump:

1. RWT insert rod pump is made of high-strength alloy material, with excellent wear and corrosion resistance, long-term stable operation in complex well conditions such as sand content and high mineralization, and the replacement cycle of sucker rod pump is extended.

2. The sealing structure of sucker rod pump has been specially improved, and the leakage rate is greatly reduced through the two-stage sealing design, which improves the oil recovery efficiency.

3. This sucker rod pump has a wide range of adaptations. It can be used in conjunction with conventional pumping rods and can also be adapted to new composite rods and columns to meet the equipment upgrade needs of different oil fields.

4. Sucker rod pump has great potential for intelligent transformation. It can integrate pressure and temperature sensors to realize real-time monitoring of the operating status of sucker rod pump and provide data support for the digital management of oil fields.

Common faults and solutions of sucker rod pump:

1. Stuck pump failure: It is mostly caused by sand particles, waxy deposits in the well, or the gap between the pump cylinder and the plunger is too small. When solving, it is necessary to start the sucker rod pump, clean up the impurities in the pump, check the wear of the plunger and the pump barrel, and replace the accessories if necessary; If it is a waxing problem, the sucker rod pump can be hot-washed and waxed, and regularly filled with anti-wax agent.

2. The amount of leakage increases: It is mainly caused by the lax sealing of the Versailles ball and the Versailles seat or the aging of the sealing ring. The sucker rod pump(RWT Insert Rod Pump) should be disassembled, the Verne ball and Verne seat should be ground, the aging sealing ring should be replaced, and the sealing surface should be ensured to be clean and free of damage when reassembling.

3. Pump failure caused by broken sucker rod: It will cause insert rod pump to fail to work properly. It is necessary to take out the well column and insert rod pump, check the location and cause of the breakage, replace the broken sucker rod, and check whether the inside of the insert rod pump is damaged by the impact, and then go down the well again after repair.

4. Insufficient liquid intake: It may be that the suction port is blocked or the degree of sinking is not enough. The filter of the insert rod pump suction port needs to be cleaned. If the sinking degree is insufficient, the depth of the pump can be appropriately deepened so that the insert rod pump can effectively inhale liquid.

API RWT insert pump(Sucker rod pump) customized service:

According to the needs of different oil fields, we provide exclusive API RWT insert pump(Sucker rod pump) customized services.First collect well condition data, customize the API RWT insert pump(Sucker rod pump) material according to sand content, temperature, etc., use corrosion-resistant alloy API RWT insert pump for high-corrosion wells, and add sand-proof structure API RWT insert pump(RWT Insert Rod Pump) for multi-sand wells.

We support the customization of the API RWT insert pump(RWT Insert Rod Pump) function, and can add sensors to monitor the condition of the API RWT insert pump(RWT API Insert Pumps), and we can also adjust the size of the API RWT insert pump(RWT API Insert Pumps) according to the existing tubing to adapt to the original tubing.

Each customized API RWT insert pump(RWT API Insert Pumps) in production has undergone 7 tests, and the API RWT insert pump(RWT API Insert Pumps) installation guidance is provided at the time of delivery, and the API RWT insert pump(RWT API Insert Pumps) maintenance manual is attached. The warranty is 18 months to ensure that the customized API RWT insert pump is adapted to oil fields to help efficient oil production.

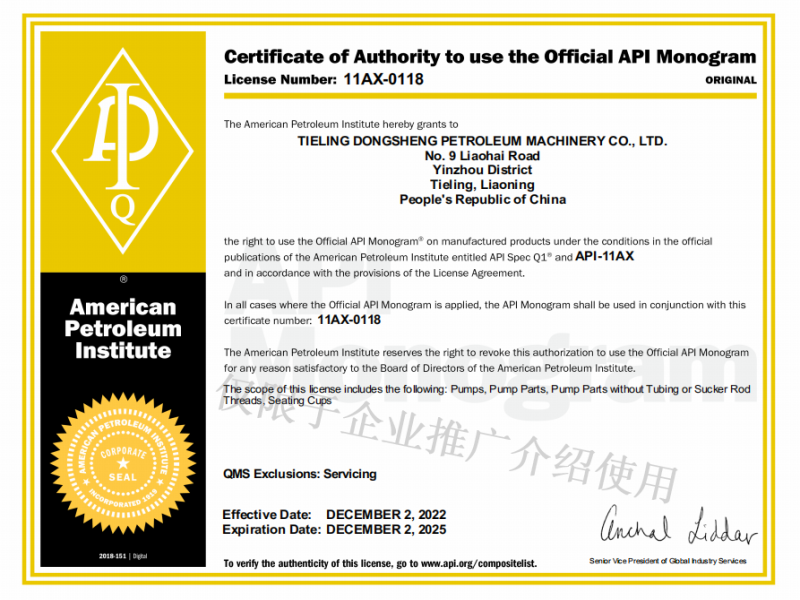

Certification of insert rod pump(RWT API Insert Pumps):

Certification

Product Title

Certification

Cooperative customer:

Shipping method:

About us:

Tieling Dongsheng Petroleum Machinery Co., Ltd. has passed the ISO 9001 quality management system certification and obtained the API11AX certificate for use. The company covers 100 kinds of pumping rod pump products and accessories such as underground RWT Insert rod pump, long plunger sand pump, drainage pump, centralizer, spraying metal plunger, alignment and uniform grinding. The company has established a complete inspection system, and implements the whole process control and inspection from raw materials, semi-finished products to finished products.