07-03/2025

Application requirements of sucker rod pump:

In the process of working of sucker rod pump, in order to ensure the long-term production capacity of oil fields, you can refer to the following contents:

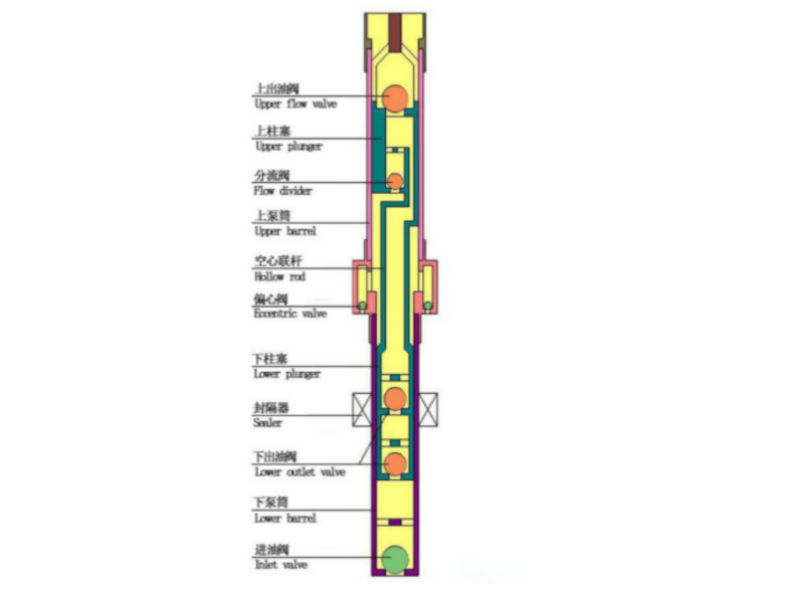

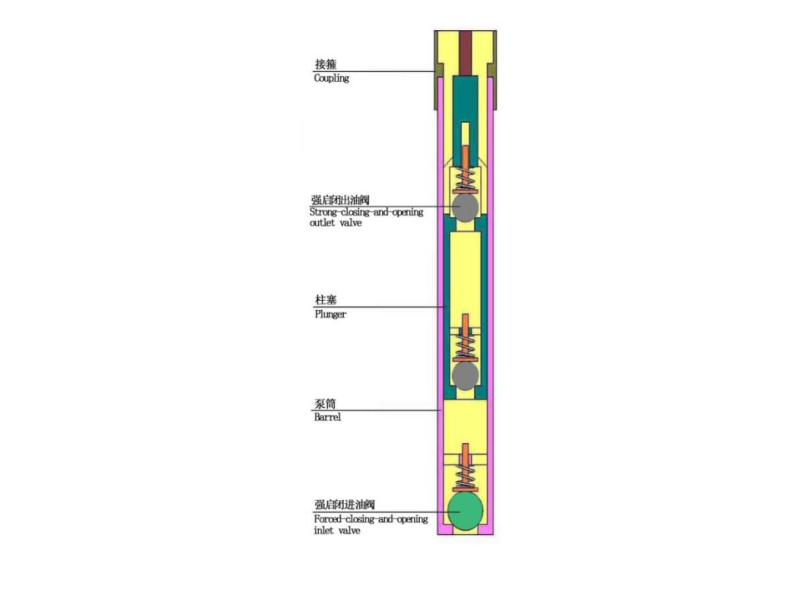

(1) the material strength of the suction valve and plunger of sucker rod pump must meet the actual use requirements, especially the pump barrel structure that bears the most pressure, which must have sufficient strength, hardness and sealing at the same time, and its overall shape will not deform when subjected to high pressure.

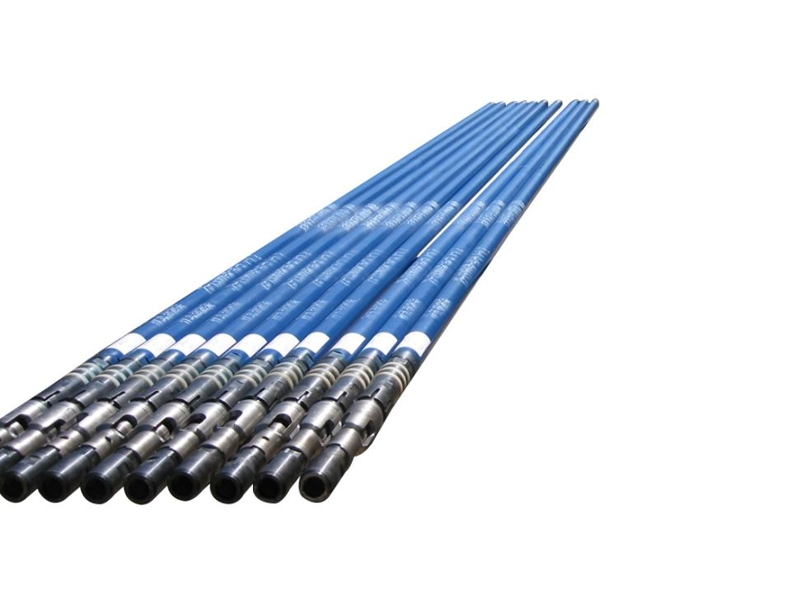

(2) sucker rod pump needs to work underground for a long time, and in this extremely closed working environment, the equipment itself needs to have extremely high stability and reliability, and must have a long service life.

(3) various valves and plungers need to meet the corresponding process requirements in terms of quality and material strength, and have high corrosion resistance, and pay attention to the impact of the working process of sucker rod pump on valves and plungers.

(4) pay attention to daily maintenance procedures, and solve various problems faced by sucker rod pump in a preventive manner.

Below, we will conduct a specific analysis of several common problems, hoping to help friends who encounter such problems. Let's read on!