API subsurface rod pump, polished rod and coupling are components of rod pumping equipment, which transmit the power of the pumping unit to the downhole pump. The API subsurface rod pump column is made up of dozens or hundreds of API subsurface rod pumps connected by couplings. During the oil production process, the API subsurface rod pump column is subjected to asymmetric cyclic loads, and the working medium is well fluid (crude oil and mineral water), and the well fluid of many pumping wells contains corrosive media. Therefore, the main failure form of API rod pump is fatigue fracture or corrosion fatigue fracture. The breakage accident of API subsurface rod pump will seriously affect the crude oil production, increase the cost of well repair, and increase the cost of crude oil.

1. Development of API rod pump:

In order to meet the needs of large pump strong extraction, small pump deep extraction, heavy oil wells, high wax content wells, corrosive wells and inclined wells, many special API rod pumps have been developed at home and abroad, such as ultra-high strength API rod pump, fiberglass API subsurface rod pump, hollow API subsurface rod pump, continuous API rod pump, electric heating API subsurface rod pump, wire rope API subsurface rod pump and aluminum alloy API subsurface rod pump, etc., and many matching parts of API subsurface rod pump columns have been studied, such as long stroke high strength polished rod, toothless polished rod clip, rotator, shock absorber, graphite adjustable center polished rod sealing box, roller coupling centralizer, magnetic anti-wax device and pump empty controller, etc., which further improve the service life and application range of API subsurface rod pump.

2. Structure and use of API rod pump:

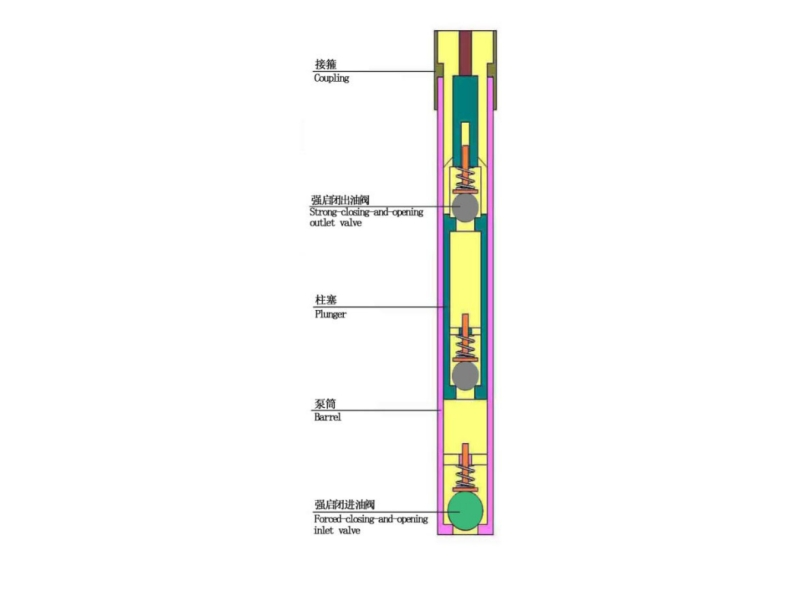

API subsurface rod pump is connected to form API rod pump column through coupling, connected to pumping unit through bare rod at the top, and connected to the plunger of pumping unit at the bottom, which is used to transmit the reciprocating motion of the donkey head suspension point of the surface pumping unit to the downhole pump.

API subsurface rod pump thread failure is often manifested as thread breakage. However, due to the lower concave design of modern APIAPI subsurface rod pump thread and the use of rolling instead of turning when manufacturing thread, the occurrence of such problems has been greatly reduced.

The structure of ordinary API subsurface rod pump and its rod head is shown in the figure below. Its rod body is a solid circular cross-section steel rod with upset rod heads at both ends. The rod head consists of an external thread joint, a relief groove (stress dispersion groove), a thrust surface shoulder, a wrench square diameter, a flange and an arc transition zone. The external thread joint is used to connect with the coupling, and the wrench square neck is used to clamp the API subsurface rod pump when loading and unloading the API subsurface rod pump joint.

SY/T 5029-2005 "Sucker rod pump" stipulates that the rod diameters of API subsurface rod pumps are: 12.7mm (1/2in), 15.9mm (5/8in), 19.1mm (3/4in), 22.2mm (7/8in), 25.4mm (1in), 28.6mm (11/8in).

The length of API subsurface rod pump is generally 8000mm or 7620mm. In order to adjust the length of API subsurface rod pump column, there are also short API subsurface rod pumps with lengths of 410, 610, 910, 1220, 1830, 2440, 3050, 3660mm.

API SPEC 11B "Sucker rod pump" and SY/T5029-2005 divide ordinary API subsurface rod pumps into three grades: C, D and K. C-grade API subsurface rod pump is used for oil wells with light and medium loads, D-grade API subsurface rod pump is used for oil wells with medium and heavy loads, and K-grade API subsurface rod pump is used for oil wells with light and medium loads and corrosive conditions.

C-grade, D-grade and K-grade API subsurface rod pumps are made of carbon steel or manganese steel, carbon steel or alloy steel, and nickel-molybdenum alloy steel, respectively. They are generally subjected to upsetting, overall heat treatment, external thread rolling, shot peening, oil-soluble coating protection and other processes to obtain certain fatigue resistance or corrosion fatigue resistance.

3. Specific classification of API rod pump:

1. Conventional API rod pump:

Conventional API rod pump is a metal rod with a circular cross section and upsetting at both ends. The upsetting part has a square cross section for connecting threads and snap-on wrenches. The diameters of API rod pump are 13, 16, 19, 22, 25 and 29 mm (i.e. 1/2, 5/8, 3/4, 7/8, 1 and 1 1/2 in). The lengths are generally 7.62 m and 8 m, and the API standard stipulates 7.62 m and 9.1 m.

According to the provisions of the national standard and API standard, conventional API rod pump can be divided into:

C-grade API rod pump-the material is carbon steel or manganese steel, such as C-Mn steel API subsurface rod pumps, with a tensile strength of 620-794 MPa.

D-grade API rod pump-the material is carbon steel or alloy steel, such as Cr-Mo steel API subsurface rod pumps, with a tensile strength of 794-965 MPa.

K-grade API rod pump-material is nickel-molybdenum alloy steel, Figure NC-Mo or Ni-Cr steel API subsurface rod pump, tensile strength is 588-794MPa.

China's API rod pump has been standardized and a unified code has been specified.

2. Special API rod pump:

In addition to the existing conventional API rod pump, some new API subsurface rod pumps have been developed, mainly ultra-high strength API subsurface rod pump, fiberglass API subsurface rod pump, hollow API subsurface rod pump and continuous API subsurface rod pump.

① Ultra-high strength API rod pump:

Compared with D-grade API rod pump, this API subsurface rod pump is a new strength grade with higher performance indicators and higher bearing capacity. When the minimum stress is 0-102MPa, the allowable stress value exceeds the D-grade API subsurface rod pump by more than 35%. The model identification method of ultra-high strength API rod pump is: such as CYG7/8HL9140, which means HL type API subsurface rod pump with a diameter of 7/8" (22.2mm) and a length of 140mm (30ft).

② API rod pump made of steel instead of steel has the main advantages of light weight and strong corrosion resistance. The main disadvantage is that it cannot withstand axial compression load and the operating temperature generally cannot exceed 163℃. FRP API rod pump is indicated by the rod diameter, maximum operating temperature and end joint level, such as 7/8"-93℃-A, which means API rod pump with a rod diameter of 7/8in, a maximum operating temperature of 93℃ and an end joint level of A.

③ Hollow API rod pump: The main features of the hollow API subsurface rod pump are: its inner hole can transport oil, and the oil passes through at a higher flow rate, which improves the ability to carry sand and mechanical impurities; it can reduce the maximum load of the polished rod and reduce the number of well repairs; the inner hole is used to inject hot oil, hot water or steam into the bottom of the well to reduce viscosity and remove wax, etc. Therefore, the hollow API subsurface rod pump is particularly suitable for heavy oil wells, sand-containing wells and pumping wells that require continuous injection of media.

In addition to the above-mentioned special API rod pump, there are also continuous API subsurface rod pump, flexible API subsurface rod pump, electric heating API rod pump, aluminum alloy API subsurface rod pump, etc., each of which has different uses and characteristics.

4. Classification of API rod pump, polished rod and coupling threads:

In order to ensure the reliability of the threaded connection of API rod pump, polished rod and coupling, avoid breakage during production, generate well repair costs, and thus increase crude oil costs, it is necessary to detect the threads to ensure normal production efficiency and output.

1: Gauge model (14 types in total)

For testing external threads: P1, P2; P3, P4; P5, P6; P7, P8;

For testing internal threads: B1, B2; B3, B4; B5, B6;

2: Name and purpose

2.1 For testing API rod pump external threads:

(1) P7 truncated crest external thread through-end calibration plug gauge:

This gauge represents the maximum allowable pitch diameter of the external thread and is used for: calibrating the matching ring gauge P8 and the corresponding working ring gauge, checking the end face verticality of the working ring gauge shoulder, detecting the wear of the matching ring gauge, and shaking test.

(2) P8 external thread through-end ring gauge:

This gauge is paired with the external thread through-end plug gauge P7. When used as a calibration gauge, it can be used for arbitration when there is a dispute in the external thread inspection.

(3) P5 truncated tooth type external thread stop end calibration plug gauge:

This gauge represents the minimum allowable middle diameter of the external thread and is used to: calibrate the paired ring gauge P6 and the corresponding working ring gauge, check the wear of the paired ring gauge, and conduct shake test.

(4) P6 external thread stop end ring gauge:

This gauge is paired with the external thread stop end plug gauge P5. When used as a calibration gauge, it can be used for arbitration of disputes in external thread inspection.

2.2 Inspection of API rod pump internal threads (couplings):

(1) B1 internal thread through end ring gauge (calibration ring gauge):

This gauge represents the minimum allowable middle diameter of the internal thread. It is used to inspect the through end internal thread plug gauge B2 and the corresponding working plug gauge, and can also be used to inspect the verticality of the shoulder end face of the working plug gauge.

(2) B2 internal thread through end plug gauge:

The internal thread through end plug gauge B2 is used to inspect the polished rod coupling and the reducing coupling, but cannot inspect its 9° taper.

This gauge is paired with the internal thread through end ring gauge B1. When used as a calibration gauge, it can be used for arbitration when there is a dispute in the external thread inspection.

(3) B3 internal thread taper ring gauge (ring gauge for checking the fit of the taper surface)

The internal thread taper ring, plug gauges B3 and B4 are used for polished rod couplings and reducers, not for API rod pump couplings.

This gauge represents the basic taper of the internal thread and can be used as a standard gauge to determine the distance between the paired plug gauge B4 and the corresponding working plug gauge end face.

(4) B4 internal thread taper plug gauge:

The internal thread taper plug gauge B4 and ring gauge B3 are used for polished rod couplings and reducers, not for API rod pump couplings.

(5) B5 internal thread stop ring gauge (verification ring gauge)

This gauge represents the maximum allowable mean diameter of the internal thread. It is used to verify the paired plug gauge B6 and the corresponding working plug gauge, API rod pump, polished rod and reducer.

(6) B6 internal thread stop plug gauge: This gauge is paired with the internal thread stop ring gauge B5. When used as a calibration gauge, it can be used for arbitration in case of disputes in internal thread inspection.

2.3 For inspection of polished rod external thread joints:

(1) P1 external thread through-end calibration plug gauge: This gauge represents the maximum allowable middle diameter of the external thread and is used to: calibrate the paired ring gauge P2 and the corresponding working ring gauge, check the verticality of the working gauge shoulder end face, detect the wear of the paired ring gauge, and perform a shake test.

(2) P2 external thread through-end ring gauge: This gauge cannot be used to check the 9° taper. This gauge is paired with the external thread plug gauge P1. When used as a calibration gauge, it can be used for arbitration in case of disputes in external thread inspection.

(3) P3 external thread taper plug gauge (plug gauge for checking the fit of the taper surface)

This gauge represents the basic taper of the external thread. It can be used as a standard plug gauge to determine the distance between the paired external thread taper ring gauge P4 and the corresponding working ring gauge end face (when P4 is used as a working gauge, it can be compared with the P4 calibration gauge)

(4) P4 external thread taper ring gauge:

This gauge is paired with the external thread taper plug gauge P-3. When used as a calibration gauge, it can be used for arbitration when there is a dispute in the external thread inspection.

(5) P5 truncated tooth type external thread stop end calibration plug gauge

This gauge represents the minimum allowable mean diameter of the external thread and is used to: calibrate the paired ring gauge P6 and the corresponding working ring gauge, check the wear of the paired ring gauge, and perform a shake test.

(6) P6 external thread stop end ring gauge:

This gauge is paired with the external thread stop end plug gauge P5. When used as a calibration gauge, it can be used for arbitration when there is a dispute in the external thread inspection.

Note: From the above introduction to gauge types, we can see that the P5 truncated tooth type external thread stop end calibration plug gauge Both plug gauges and P6 external thread stop ring gauges can be used for API rod pump and polished rod external thread inspection.

The details of API rod pump, polished rod and coupling thread gauges are as follows:

1. P8 external thread T-end ring gauge.

2. P6 external thread Z-end ring gauge (used to inspect API rod pump and polished rod external thread joints)

3. P7 truncated top external thread T-end calibration plug gauge.

4. P5 truncated top external thread Z-end calibration plug gauge.

5. B2 internal thread T-end plug gauge (used to inspect internal thread joints of API rod pump, polished rod and reducing coupling)

6. B6 internal thread Z-end plug gauge (used to inspect internal thread joints of API rod pump, polished rod and reducing coupling)

7. B1 internal thread T-end ring gauge (verification ring gauge)

8. B5 internal thread Z-end ring gauge (verification ring gauge)

9. B3 internal thread taper ring gauge (matching ring gauge)

10. B4 internal thread taper plug gauge (used to inspect internal thread joints of polished rod and reducing coupling)

11. P4 external thread taper ring gauge (used to inspect external thread joints of polished rod)

12. P3 external thread T-end taper plug gauge (matching plug gauge)

13. P2 external thread T-end ring gauge (used to inspect external thread joints of polished rod)

14.P1 truncated top external thread T-end calibration plug gauge

Inspection of API subsurface rod Gauges to be used for pump:

P8 (T): Male thread through end ring gauge.

P6 (Z): Male thread stop end ring gauge.

B2 (T): Female thread through end plug gauge.

B6 (Z): Female thread stop end plug gauge.

Working gauges to be used for inspection of polished rod:

P2 (T): Male thread through end ring gauge.

P6 (Z): Male thread stop end ring gauge.

P4 (cone): Male thread taper ring gauge.

B2 (T): Female thread through end plug gauge.

B6 (Z): Female thread stop end plug gauge.

B4 (cone): Female thread taper plug gauge.

Well, that’s all for this issue. We will continue to share more standards and usage guidelines for oil pumping equipment in the future, so stay tuned!