In western and southern India, many oil fields in the middle and late stages have encountered such problems:

Less than half a year after the sucker rod pump was replaced, abnormal noises began to appear in the well, either broken rods or eccentric wear. In serious cases, the well was directly stopped for repair, wasting a lot of manpower and material resources.

In fact, the root cause of the problem is not complicated - the well conditions are changing, but the sucker rod pump used has not kept up. Faced with this situation, more and more Indian customers are beginning to try to use China's API sucker rod pump, not because we say it well, but because these sucker rod pumps are indeed durable and long-lasting on site.

It is under such demand that the sucker rod pump made in China is accepted and recognized by more Indian customers. Many of our cooperative customers were actually skeptical at first, but after using several batches, they gave feedback saying: "I didn't think too much, but it is indeed very stable." This is their true evaluation.

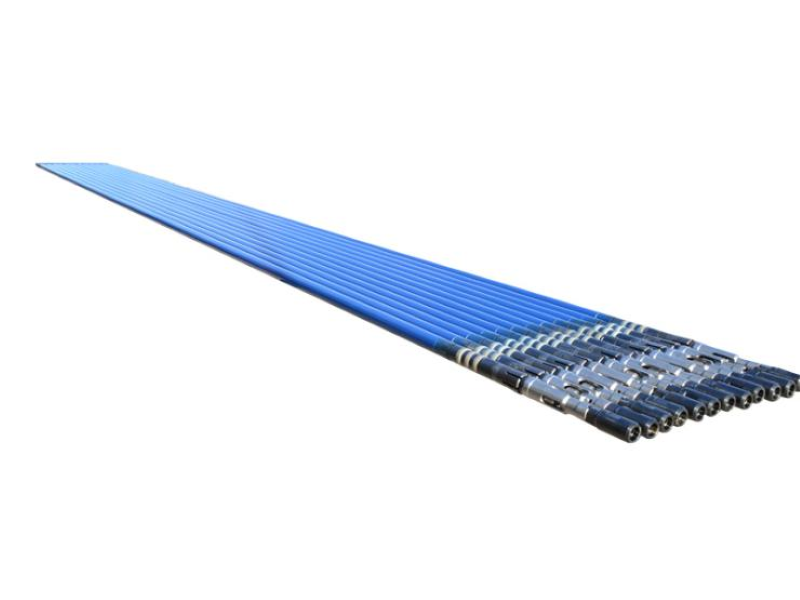

Now many Chinese manufacturers can provide different types of sucker rod pumps according to specific well conditions. For example, conventional high-strength rods are suitable for deep wells and high-load environments. If the well contains a lot of sulfur and is severely corroded, special coatings or models with corrosion-resistant materials should be used. For example, if the well is highly deviated and has severe eccentric wear, a guide can be installed to extend the service life and reduce the frequency of maintenance caused by broken rods and eccentric wear. These products not only meet API standards, but can also be packaged and designed according to customer needs to ensure that all parameters match before going down the well.

There is no fancy saying about cost, but it is cost-effective. It does not mean that we are cheap and of poor quality, but that the domestic supply chain is complete, and the materials, processing, and transportation are well controlled, so the price is naturally reasonable. Many Indian customers told us that they used European and American brands of sucker rod pumps before, and the equipment budget alone accounted for a large part of a project. After switching to our products, the procurement cost has been reduced a lot, the underground operation is more stable, and the maintenance cycle has been extended, which is particularly critical for them to control the total cost.

Delivery and response speed are also a point of concern. Many of our conventional models are in stock. If the order is placed in time, the factory can organize the delivery in a few days. If the customer has special requirements, such as customized length, thread or accessories, our technical department can quickly follow up with the plan. In the past, there were customers who changed their plans temporarily, and we also helped coordinate production as soon as possible to match the construction period as much as possible.

Once, the customer we served was an onshore oil field in western India. The original product had to be inspected every six months. After changing to our coated sucker rod pump, there was no problem for more than a year. The other party's project manager later sent us a special email saying "Your rod has saved us a lot of trouble."

In the final analysis, the sucker rod pump is not a complex high-tech equipment, but it really cannot go wrong. It is not as conspicuous as a pump or control system, but once a problem occurs, it affects the operation of the entire well. This is why more and more Indian customers choose to cooperate with domestic manufacturers for a long time after comparing prices and trying several batches of goods, especially teams like us who have been focusing on this type of product for more than ten years.

If you are doing old well maintenance, low-yield well efficiency improvement, or have a batch of new wells that need to be equipped with sucker rod pumps, we can provide complete technical parameters, adaptation solutions and samples, and can also cooperate with your budget and delivery arrangements. We understand the uncertainty of the site and the rhythm of your project, so we are willing to be a stable and worthy partner.