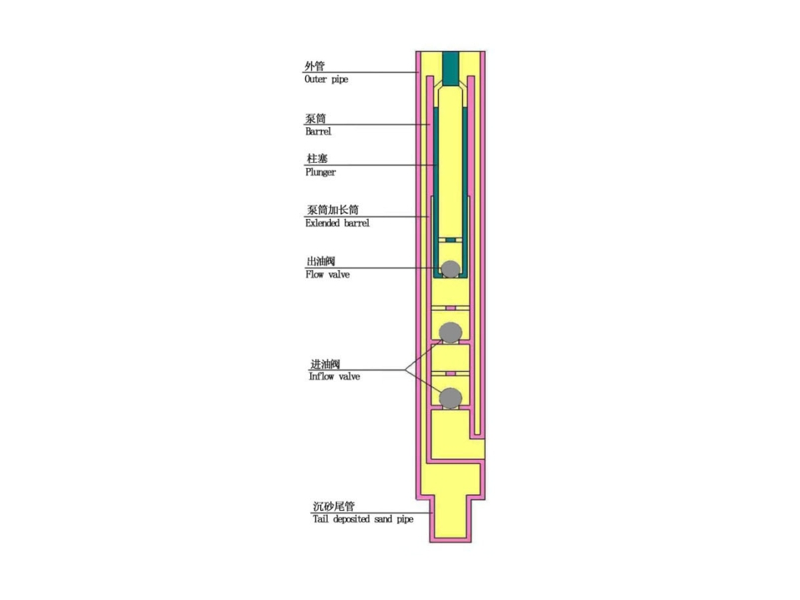

When I disassembled the long plunger sand control subsurface pump that had been used for almost a year with the customer on site, the first thing I noticed was that the wear on the contact surface between the plunger and the pump barrel was almost negligible. The customer's words at the time impressed me deeply: "I didn't expect that this well condition could withstand so long." This pump is the 25 106th long plunger sand control pump we recommended. Their oil wells are typical well sections with high sand content and strong liquid corrosiveness. Many customers asked us, what does the 25 106th model mean? We are used to explaining that 25 is the diameter of the pump barrel, 106 represents the length, and th is the version with enhanced structure. In practical applications, it is not just a parameter number, but also represents a type of pump type structure optimized for the problem of "high wear, high sand, and easy to get stuck".

During our internal research, we compared the continuous extraction time of the long plunger sand control subsurface pump and the ordinary pump in the sand-containing well, and the average gap in the service life was more than 40%, especially in China's Shengli, Zhongyuan, and Qinghai oil fields, where the cases are very solid. The core of the long plunger sand control subsurface pump is not the three words "long plunger", but the structural design around the key actions of "letting sand sink, not entering the seal, and pump not biting".

The long plunger sand control subsurface pump we recommend is a bottom oil inlet structure, abandoning the original lateral oil inlet method. This change avoids sand bridge blockage in many sites and reduces the frequency of unblocking operations. Some people are worried that the long plunger has a large running resistance. In fact, on the contrary, it has smoother running resistance, and it is not easy for the plunger to be blocked due to poor oil return when it goes down. This is particularly reported by on-site workers after maintenance.

There is a typical well, Shengtuo 39221 well, which originally used a conventional pump. The pump efficiency dropped from 71% to 33% in just 6 months. Both ends of the plunger were severely scratched, and the rod coupling was even worn through. In 1999, we replaced the 25 106th long plunger sand control subsurface pump we recommended, and optimized the structure with the weighted rod. The pump efficiency remained above 63%, and the pumping was stable for 347 days without any maintenance due to stuck pump. We have done a lot of such well cases, and often take them out for customers to refer to. Speaking with data is actually the most convincing. After reading it, some customers always worry that there are too many models and don’t know how to choose. In fact, it is very simple. Our on-site engineers can quickly match the appropriate model based on several indicators such as sand content, well depth, whether there is corrosive medium, pump efficiency historical data and pump inspection cycle.

If you see a model like "25 106th1.2-5.7", the following parameters may indicate the displacement range or working range of the pump, which is a further refined customized model. You only need to tell us the well conditions, and we will convert these cumbersome parameters into the most suitable configuration plan. According to our company's delivery records, more than 1,600 long plunger sand control subsurface pumps have been stably supplied, covering North China, Northwest China and some overseas oil fields. During the follow-up visits, almost all feedback was that the pumps had light wear, stable pump efficiency and long maintenance intervals. More importantly, maintenance is not that complicated, and the conventional oil production plant tool team can handle it. No special spare parts are required, and the valves and valve covers are all standardized. This was also the focus of our structural development at the time. We hope to do more than just sell you a pump, but also help you solve the problems of sand grinding and sand jamming that are encountered repeatedly every year under complex well conditions. If you are interested in the long plunger sand control subsurface pump we recommend, or need to view the model parameter table and historical application cases, please contact our technical team. We are willing to use field experience and data to help you extend the production cycle of the well.