I. Safety:

1. Safety protection measures:

During the storage, collection, transportation, lifting, placement, use and maintenance of sucker rod pumps, all operations must comply with local safety regulations and operating procedures. All operators must wear work clothes during the operation and wear safety helmets during lifting operations.

2. Safety risks:

The pump barrel is equipped with a movable plunger. When lifting, pay attention to the plunger sliding out of the pump barrel and try to ensure the balance of the pump body.

II. Instructions for use of tubular pumps:

1. Transportation, loading and unloading and storage:

(1) The sucker rod pump is a long and precise equipment. When loading and unloading, pay attention to smooth lifting and lowering. Take measures to prevent collision and falling to avoid damage.

(2) When transporting by car, the pump should be installed on the bracket and fixed. The pump bracket should be placed stably and stacking should be avoided as much as possible. When stacking, no more than two layers should be stacked and fixed to prevent falling during transportation.

(3) When transporting the pump to the oil field, the pump should be installed on a special horizontal bracket and transported by a special vehicle. The distance between adjacent support points on the bracket should not exceed 1.5 meters.

(4) The sucker rod pump should be stored in a dry, clean and ventilated warehouse. When placed horizontally indoors, a bracket should be placed. When stored in multiple layers, a bracket should be placed on each layer. The distance between adjacent support points should not exceed 1.5 meters.

(5) If the sucker rod pump is stored outdoors, the protective threads and protective caps at both ends of the sucker rod pump must be tightened, and good support should be provided. Sun protection, moisture protection and waterproof measures should be taken.

2. Downhole steps:

(1) Before transporting the sucker rod pump to the well site, the pump's markings and quality certificates should be carefully checked to ensure that they are correct. Check whether all connecting threads are tightened. If they need to be re-tightened, apply thread oil first and then tighten them. Use the pull rod connection plunger to pull back and forth in the pump barrel to test its flexibility. For sucker rod pumps that have been stored for a long time, their integrity should be checked first. Only when there is no problem can they be downhole.

(2) According to the well repair work instructions, the oil pipes and sucker rods to be lowered into the well should be carefully inspected, cleaned, and measured. Ensure that there is no iron scale, sand or other debris in the oil pipes, and ensure that the threads of the oil pipes and sucker rods are not damaged.

(3) According to the well repair design, the pump tail pipe and downhole tools are lowered in sequence. When the sucker rod pump is lowered into the well, the thread protector and the cap should be unscrewed first, and then the plunger should be pulled out and placed flat in a clean place. The lifting card is placed under the pump barrel coupling, and it is lifted by the well hauling machine. After applying thread oil to the external thread of the reducer coupling of the sucker rod pump fixed valve, it is connected with the internal thread of the oil pipe in the well, tightened with hydraulic pliers, and then slowly lowered into the well. Finally, the oil pipes are lowered to the wellhead in sequence. The external threads of each oil pipe should be coated with thread oil.

(4) After the pump barrel is lowered to the position in the well, the oil pipe is pressed, and the plunger is lowered after it passes the test. Before the plunger is lowered into the well, check whether there are any bumps on its surface, and wipe its surface clean before lowering it into the well. When the plunger is about to enter the pump barrel, the speed of going down into the well should be slowed down to prevent the plunger from being damaged when entering the pump barrel. After the plunger enters the pump barrel and hits the pump, adjust the anti-impact distance and hang the pump.

(5) The sucker rod pump is a precision equipment. It is strictly forbidden to clamp the pump barrel and plunger with a pipe clamp. After the sucker rod pump arrives at the well site, before going down into the well, it should be placed horizontally with a fulcrum in the middle to prevent it from bending and deforming.

(6) In the case where the pump diameter of the sucker rod pump is larger than the inner diameter of the connected oil pipe, a release joint (connected to the upper part of the pump barrel) and a docking device (connected to the plunger and sucker rod) are required.

3. Precautions during operation:

(1) First check the pulling flexibility of the sucker rod pump on the ground. (2) When carrying out the downhole operation, first lower the pump barrel assembly together with the oil pipe string into the designed pump hanging depth. (3) Conduct a pressure holding test. Check the sealing of the fixed valve and the oil pipe. (4) The plunger assembly is lowered into the well along with the sucker rod string. When the rod column approaches 2 rod columns above the pump hanging depth, the rod lowering speed must be slowed down until it hits the pump. After hitting the pump, the rod column should be kept without any rotation, and the rod column should be lifted to adjust the stroke distance. Replace the rod. (5) Start pumping several times and test the wellhead valve. If there is gas discharge, start pumping normally. (6) Note: During normal pumping, at the lower limit of the downstroke, the plunger should be ensured not to hit the pump. (7) Note: If it is necessary to pull out the fixed valve, the rod column should be slowly lowered to the pump hitting position, and the rod column should be rotated clockwise (3-6 turns according to the pump hanging depth and the condition of the rod column) to make the puller hook with the hanging head on the upper part of the fixed valve cover, and then be pulled out of the oil well with the rod column.

III. Instructions for use of sucker rod pumps:

1. Transportation, loading and unloading and storage:

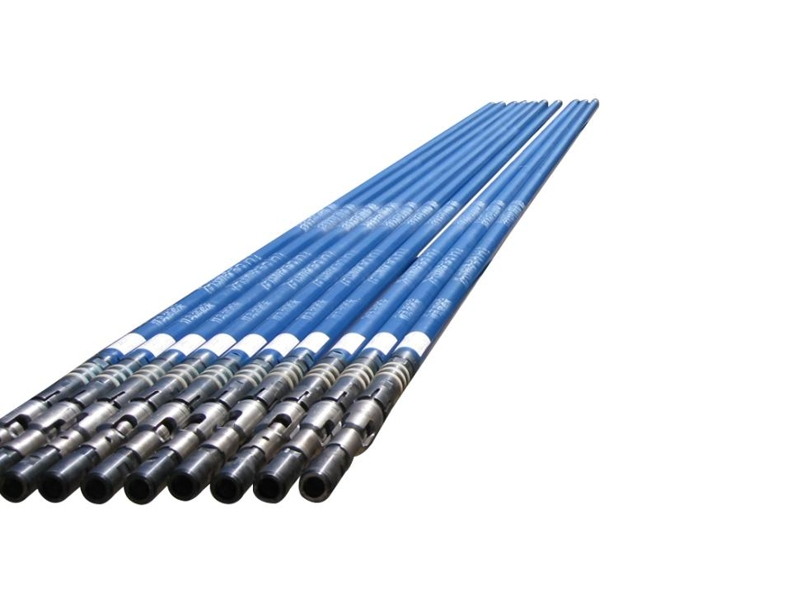

(1) The sucker rod pump is a long and precise equipment. When loading and unloading, it is necessary to pay attention to the smooth lifting and lowering, and take measures to prevent collision and falling to avoid damage. During transportation of the sucker rod pump, the support seal assembly should be protected with a protective cap or cotton cloth to prevent damage to the sealing surface.

(2) When transporting by car, the pump should be installed on the bracket and fixed. The pump bracket should be placed stably and avoid stacking as much as possible. If stacking is necessary, it should not exceed two layers and should be fixed to prevent it from falling during transportation.

(3) When transporting on-site in the oil field, the pump should be installed on a special horizontal bracket and transported by a special vehicle. The distance between adjacent support points on the bracket should not exceed 1.5 meters. Before transporting the sucker rod pump to the well site, insert the sucker rod pump into a new oil pipe to prevent damage to the seal caused by collision.

(4) The sucker rod pump should be stored in a dry, clean and ventilated warehouse. When placed horizontally indoors, a bracket should be placed. When storing in multiple layers, a bracket should be placed on each layer. The distance between adjacent support points should not exceed 1.5 meters.

(5) If the sucker rod pump is stored outdoors, the protective threads and protective caps at both ends of the sucker rod pump must be tightened, and good support must be provided. Measures to prevent sunlight, moisture and water must be taken.

2. Steps for lowering the rod pump into the well:

Preparation before lowering the pump:

(1) Check whether the pump to be lowered into the well is damaged or corroded due to improper storage, and whether the connecting threads of each part are tightened.

(2) Check the flexibility of the plunger pull. All oil pipes must be cleaned and 100% tested by the diameter gauge to remove impurities and foreign matter in the sucker rod and coupling.

(3) Read the operation instructions carefully and strictly follow them.

Pump lowering operation process:

(1) According to the design of the operation instructions, lower the tail pipe of the required length of the well.

(2) Lower the pump support joint (pay attention to the direction) along the oil pipe to the designed depth.

(3) Lower the corresponding number of oil pipes according to the pump hanging depth to seal the wellhead. To verify whether the oil pipe is leaking, you can also connect a "pressure test ball seat" to the tail of the oil pipe, and perform a pressure test on the oil pipe. After the pressure test is completed, increase the pressure and remove the pressure test ball seat.

(4) When lowering the pump, do not install a lifting card on the pull rod to lift the pump. Use a square clip with the teeth removed to fix it at the "reduced diameter" at the top of the pump. Install a lifting card here and lift the pump so that the pump goes down with the sucker rod to the pump hanging depth. When approaching the support joint, slow down the downward speed. When the sucker rod no longer goes down, mark it on the rod. At this time, the sum of the total length of the sucker rod and the pump should be close to the design depth.

(5) After connecting the bare rod, lift it up. The lifting length is about 3 meters. Let it fall and hit the pump so that the locking device is sealed in the support joint.

(6) Adjust the anti-impact distance and install the anti-blowout box.

(7) Pump and hold the pressure according to the requirements of the operation instructions and check the pump efficiency. The rod pump seat can only be reliable.

(8) If there is a problem with the pressure test, it needs to be re-sealed. (That is, carry out work in item (5))

3. Application of supporting technology for sucker rod pump:

(1) It is recommended to use tubing anchor as much as possible to reduce stroke loss and increase pump efficiency. (2) The first sucker rod connected to the upper part of the plunger assembly should be equipped with a sucker rod stabilizer to reduce eccentric wear. (3) For sand-containing and gas-containing oil wells, sand anchors and gas anchors should be used to ensure normal and efficient production of the oil wells. (4) Try to use a long stroke and slow stroke working system. (5) Reasonably match the rod column combination and the tubing column combination.

4. Precautions for using sucker rod pump:

(1) API type rod pump is an inserted sucker rod pump, that is, the API type rod pump is lowered into the designed pump hanging position in the tubing with the sucker rod column. The inner hole of the tubing should be clean and 100% inner hole inspection should be carried out with a corresponding specification of the bore gauge; (2) The first sucker rod connected to the upper part of the plunger assembly should be equipped with a sucker rod stabilizer. (3) The plunger of the sucker rod pump cannot extend out of the pump barrel, that is, it can only move up and down in the pump barrel. When selecting the length of the pump barrel, it should be made to meet the requirements of stroke and anti-stroke distance. The general rule is: (pump barrel length + total length of upper and lower extension couplings) > (stroke + plunger assembly length + total length of anti-stroke distance); (4) During the operation of the API type rod pump, due to slight sand jamming and other reasons, the API type rod pump may be disengaged from the sealing locking device. The sucker rod string should be moved and the pump should be re-seated; (5) In order to give full play to the advantages of the API type rod pump, high-quality tubing and sucker rods should be used, the pipe string and rod string should be optimized, and management should be strengthened (such as wax cleaning, sand prevention and other measures) to achieve the purpose of extending the pump inspection cycle, increasing pump efficiency, and not lifting the pipe string during operation.

We will share this content here! More knowledge about oil wells, artificial lift, etc. will be shared in the future. Stay tuned!