1. Description of the problem:

When the pumping well is abnormal during the production process, it is necessary to perform maintenance inspection of the deep well oil well pump. Due to scaling, the piston of some operating oil wells is stuck in the pump barrel of the deep well oil well pump, which makes it difficult to lift it during the well repair operation. At this time, it is necessary to reverse the rod pipe. The reverse rod is reversed by 2-3 operators using pipe pliers at the wellhead. The operation is very dangerous and there have been many injuries in the past. Through on-site observation and research, the sucker rod reverser is made.

Working principle:

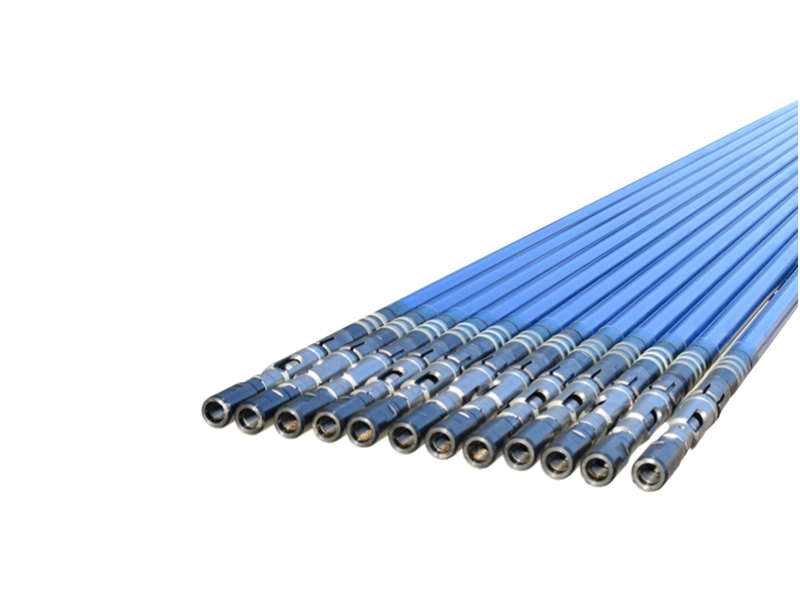

Increase the outer diameter of the sucker rod to the same outer diameter as the production tubing, cut the 500mm long tubing longitudinally, and weld the two ends to the light rod clips. When using, combine the semicircular tubing with light rod clips at both ends and fix it on the sucker rod. Use hydraulic pliers to reverse the rod, which greatly reduces the safety risk of reverse rod. At the same time, it saves labor intensity and improves work efficiency.

Application prospects:

In the production oil wells of maintenance operations, if the piston is stuck in the well, the sucker rod back-up device can be used. During the construction process, it not only reduces the safety risk, but also reduces the labor intensity, forming a good technical achievement and safety benefit.

2. Background of the problem:

During the production process of deep well oil well pump, the stroke section is soaked in oil and water for a long time, and the scale is serious. The use of the grinding machine to remove the scale increases the repair time and the repair cost of the pump.

R&D innovation: Make a round steel brush to remove the scale at a single point.

Solution: In the past, the deep well oil well pump was mainly descaled by the grinding machine. The grinding machine was mostly used for the large-area scaling of the deep well oil well pump, but for the pumping pump with a small amount of scaling in the stroke section, the grinding machine was time-consuming and laborious.

Working principle: According to the different inner diameters of the deep well oil well pump, different types of wire brushes are purchased, connected with a pull rod, and a round steel brush is made by hand to rub the scale at a single point.

Application effect: The use of round steel brushes can reduce the labor intensity of workers, reduce operating costs, save time and effort, and save costs and increase the speed of repair.

3. Description of the problem:

At present, the deep well oil well pump has been working underground for a certain period of time. The production oil well has many reasons such as abnormal operation of the deep well oil well pump or oil rod breakage and oil pipe leakage. Well repair operations are required. During each operation, the deep well oil well pump must be repaired. Since the deep well oil well pump works underground for a certain period of time, the piston surface and the inner wall of the pump barrel have different degrees of wear. The conventional overhaul is to match the piston according to the wear degree of the inner diameter of the pump barrel. The piston must be provided by the manufacturer, and the gap error is bound to be large in the matching. For this reason, a flexible piston has been developed, and the outer diameter of the piston is adjusted automatically, which solves the problem of large matching error of the deep well oil well pump.

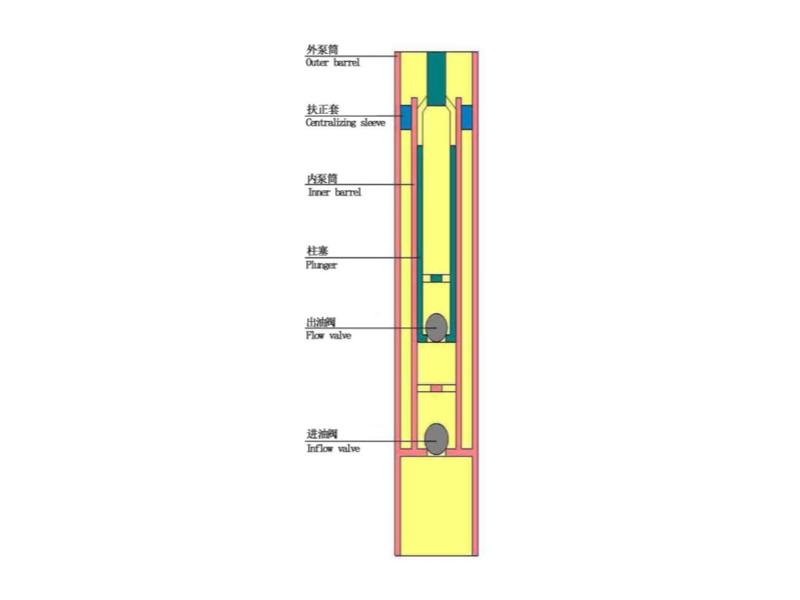

Working principle:

There are multi-stage sealing rings in the middle of the flexible piston. It is matched with the slightly worn pump barrel during maintenance. The outer diameter of the sealing ring can be adjusted according to the inner diameter of the pump barrel. The maximum diameter can be adjusted by 2mm, so that the pump barrel and piston of the deep well oil well pump meet the sealing standard (matching clearance: first level 0.02-0.07mm, second level 0.07-0.12mm, third level 0.12-0.17mm). The flexible piston has the function of scraping scale and preventing sticking. During the scaling process of the pump barrel, the sealing ring protrudes from the piston surface, so the pump barrel avoids scaling during the suction process. This piston is 1/4 shorter than the original deep well oil well pump piston and the sealing ring can shrink to prevent well sticking.

Economic benefits:

The price of the deep well oil well pump flexible piston is slightly lower than that of the normal piston. It prevents the internal structure of the pump barrel and the piston and the pump barrel from getting stuck during the normal operation of the deep well oil well pump, and prolongs the maintenance-free period of the oil well, which reduces the cost and well occupation time of maintenance operations and increases crude oil production.

Application prospects:

The flexible piston of deep well oil well pump is suitable for the repair of deep well oil well pump. It can achieve precise clearance fit in the repair of oil well pump. The clearance of deep well oil well pump can be adjusted according to the oil well block to reach any level, forming good technical achievements and economic benefits.