07-24/2025

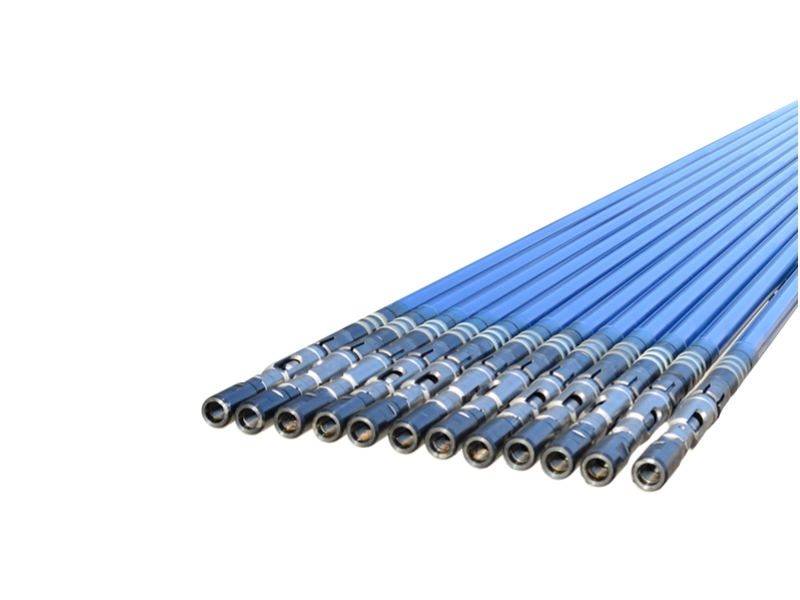

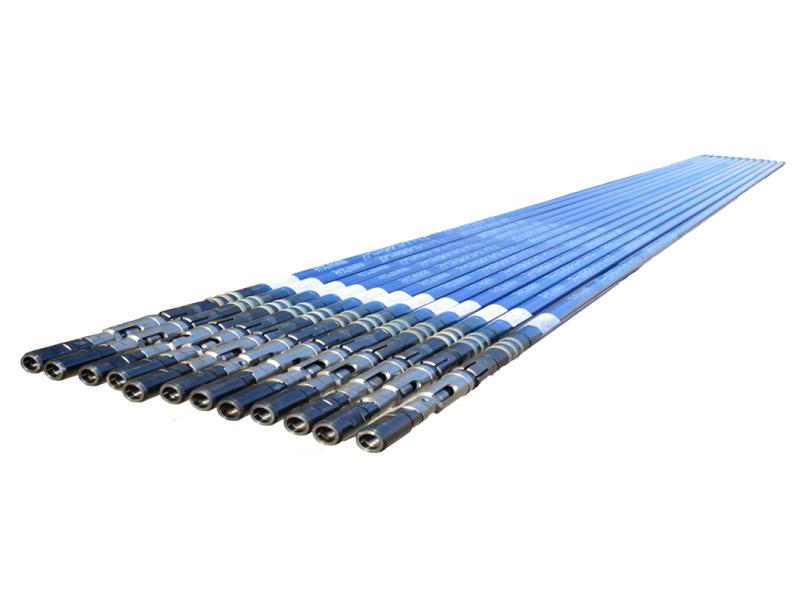

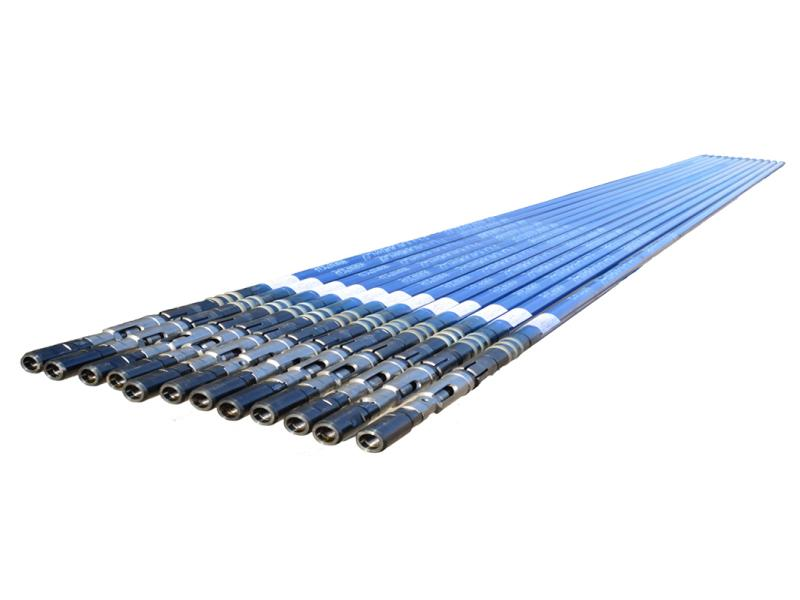

API sucker rod pump overview:

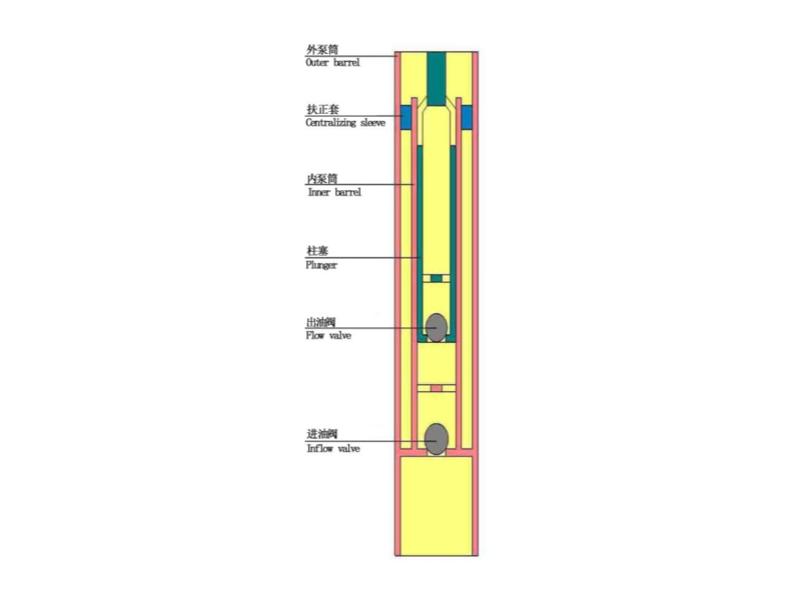

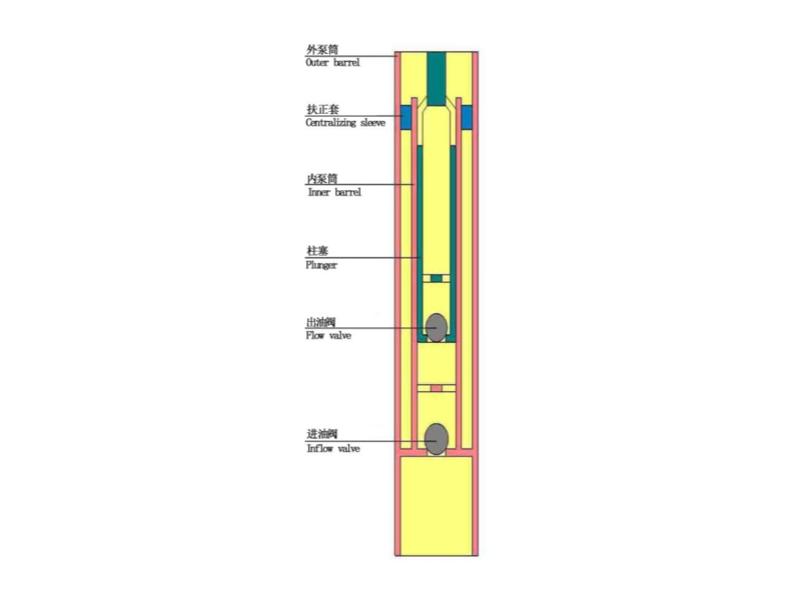

1. Structure of API sucker rod pump :

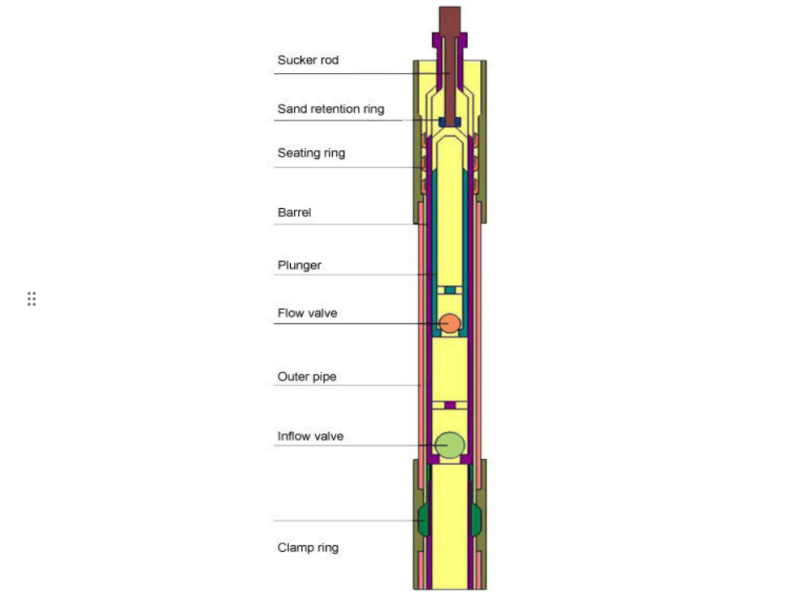

API sucker rod pump is a sleeveless integral deep well pump, which is divided into two categories: top fixed type (RHA, RWA) and bottom fixed type (RHB, RWB); the structure consists of two major parts: plunger built-in pump barrel assembly and external fixed assembly.

2. Working principle:

The working principle of API sucker rod pump is the same as that of tube pump, which relies on the reciprocating motion of the plunger to pump the well fluid to the ground. During the upstroke, the fixed valve and the annular valve are opened, the floating valve is closed, the well fluid washes the well pump barrel, and the liquid on the plunger is pumped to the ground; during the downstroke, the floating valve is opened, the fixed valve and the annular valve are closed to form a secondary compression, and the well fluid flows to the plunger through the floating valve.

3. Analysis of reasons for API sucker rod pump repair:

The main feature of API sucker rod pump repair is that the pump can be brought to the ground for repair by pulling out the sucker rod instead of pulling out the oil pipe, which reduces the workload and intensity, shortens the recovery time of the lying well, and improves work efficiency. The main problems of API sucker rod pump are: the pull rod of the pump is easy to wear and break; after the coal powder is stuck in the pump, the pump plunger is directly unsealed when it is unstuck; the leather cup of the pump body falls off, causing the seal to fail; the pump fixed valve leaks.

4. Scope of use:

API sucker rod pump is mainly suitable for vertical and inclined wells with small liquid production (well inclination <75°), wells with sand, coal powder and light scaling.