Layered oil production: Background.

In view of the current situation that the oil well joint production cannot meet the production needs due to the prominent contradiction between multiple layers and layers, the layer-stuck method is generally adopted for production. The main layer-stuck pipe string structure is as follows:

Control layer-production layer.

Production layer-control layer.

Production layer-control layer-production layer.

Through the application of various layer-stuck pipe strings, the problem of inter-layer interference is effectively solved, but the full play of the production capacity of each layer of the oil well is limited. At present, there is an urgent need for a layered co-production technology that can effectively mobilize each contributing oil layer and avoid inter-layer interference, fully tap the production capacity of the oil well, increase the production of the oil well, and improve the development time.

Layered oil production·separate layer production oil well pump

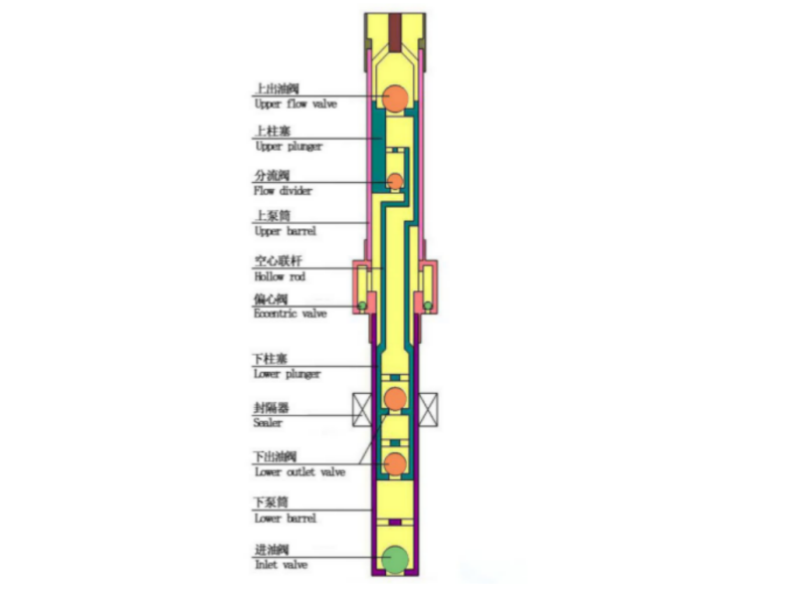

1. Structural composition:

Separate layer production oil well pump is mainly composed of sucker rod, oil outlet valve, upper plunger, upper pump oil outlet valve, upper pump barrel, center pipe, upper pump oil inlet valve, lower pump oil outlet valve, lower pump barrel, lower pump oil outlet valve, lower pump oil inlet valve, etc.

2. Technical features:

1. Separate layer production oil well pump can quickly complete the oil pumping task, save time, avoid secondary pollution, and improve the level of health and hygiene.

2. Separate layer production oil well pump can continuously output a stable amount of oil. The equipment can automatically sense the required amount of oil, add oil at regular intervals and quantitatively, ensure the stability of the oil amount, and be easy to operate.

3. Separate layer production oil well pump does not lift the oil pipe, which can save operation time, reduce operation costs, and reduce the wear of the oil pipe thread caused by the installation and removal of fasteners.

4. Separate layer production oil well pump only lifts the sucker rod column during operation, reducing the operation risk.

5. The packer isolation well adopts a layered oil production pump to avoid frequent sealing and unsealing of the packer

3. Working principle:

Our company's separate layer production oil well pump is a double-pump single-acting oil pump. The upper and lower pumps of the dual-channel oil pump work at the same time. The upper pump uses the annular space formed by the diameter difference between the upper and lower plungers to work. The upper oil enters the space through the upper pump inlet valve and is discharged through the upper pump outlet valve. The lower layer oil enters the lower pump barrel through the lower pump oil inlet valve, and then is discharged from the lower pump oil outlet valve, mixed with the upper layer oil and discharged to the ground together. This pump is suitable for stratified production of oil wells.

Technical features of stratified oil production applicable to sand-producing wells:

(1) After the pipe string is stuck with sand, the upper and lower packers can be processed step by step and pulled out separately to avoid major repairs.

(2) During the well washing operation, the well washing fluid does not enter the production layer to prevent oil layer pollution.

Data of Layered Oil Production Sucker Pump:

Pump bore | Size of connecting | Range of | Conversion | Pump | Size of connecting | Max outside |

57/38 | 2 7/8TBG | 1.2~6.0 | 41.2 | 1.92 | CYG19 | 116 |

70/38 | 3 TBG | 58.8 | 3.91 | CYG22 | 150 | |

70/44 | 3 TBG | 54.4 | 3.35 | CYG22 | 150 | |

83/44 | 3 1/2 TBG | 70.4 | 5.60 | CYG25 | 150 | |

83/57 | 3 1/2 TBG | 61.3 | 4.25 | CYG25 | 150 |

Previously, we have many customers using our stratified oil production pumps, and the actual application effect is higher than our expectations. If you are interested in our products, please contact us for more information about the products.

Please contact our foreign trade manager: Jason

Mobile phone: +86-13052798822

Email: jason@tldspm.com

Whatsapp: +86-15104247781