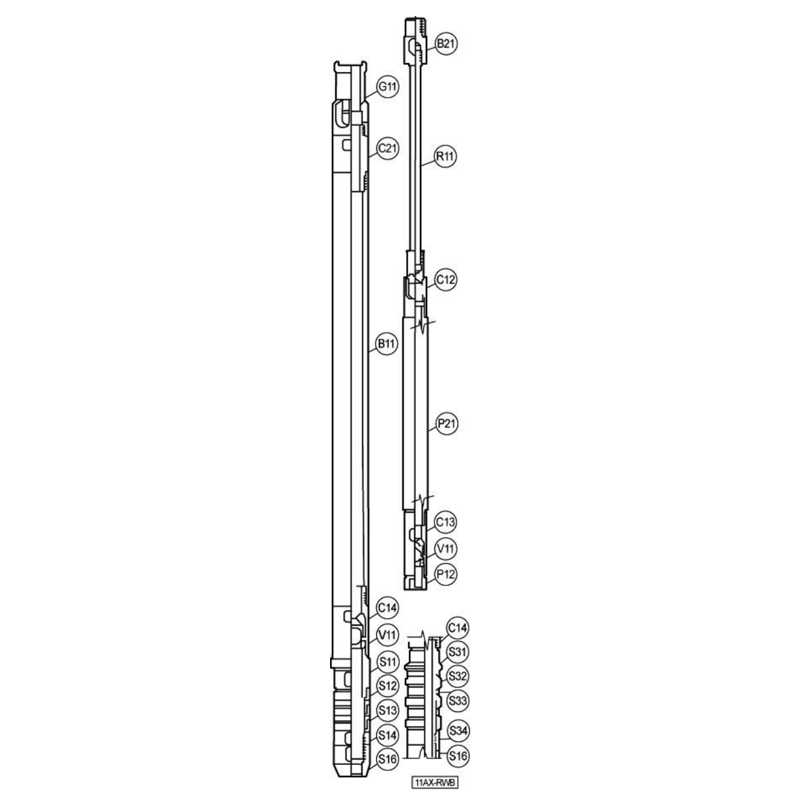

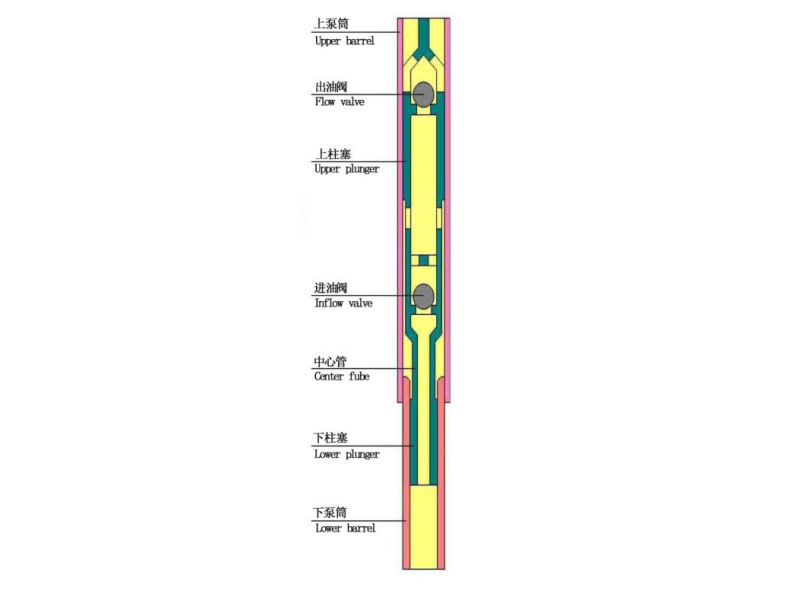

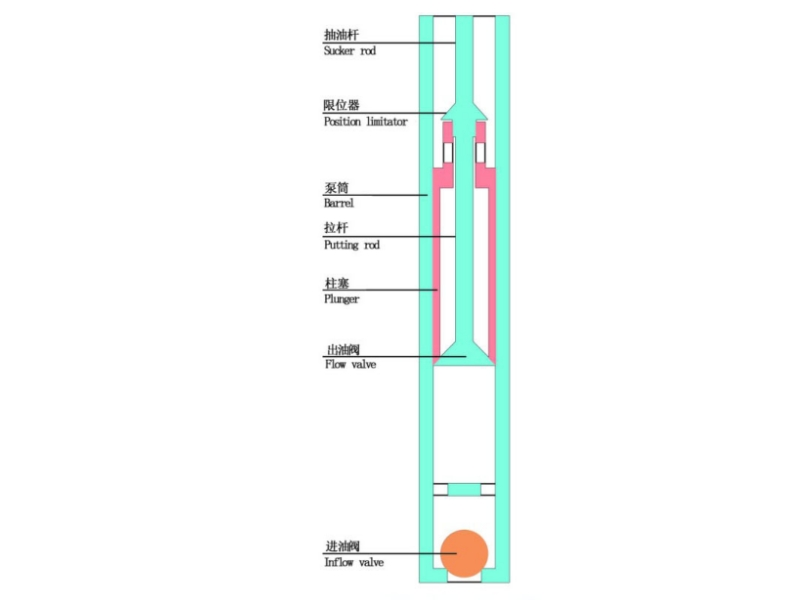

Forced Opening Valve Type Insert Pump

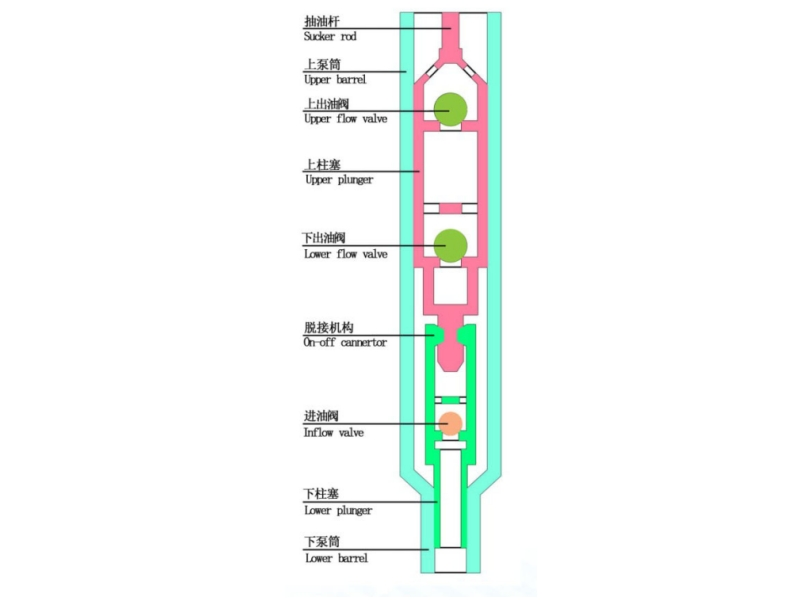

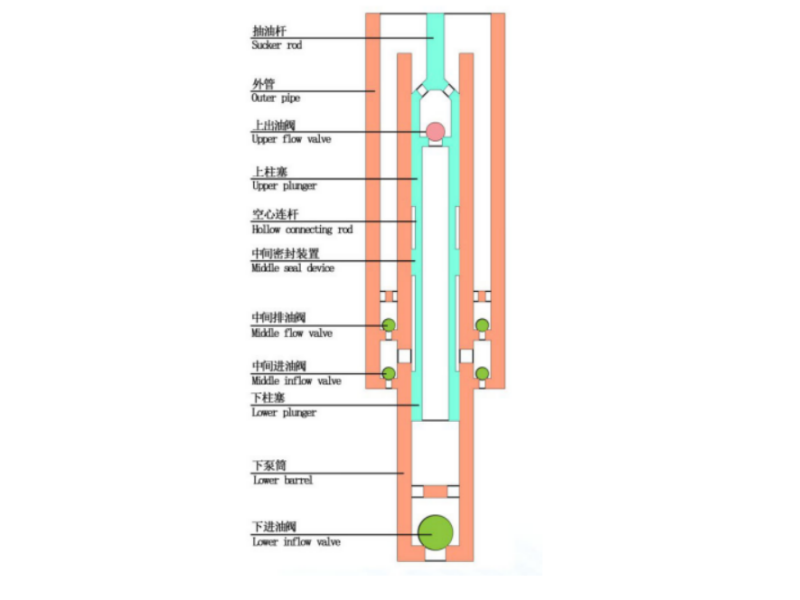

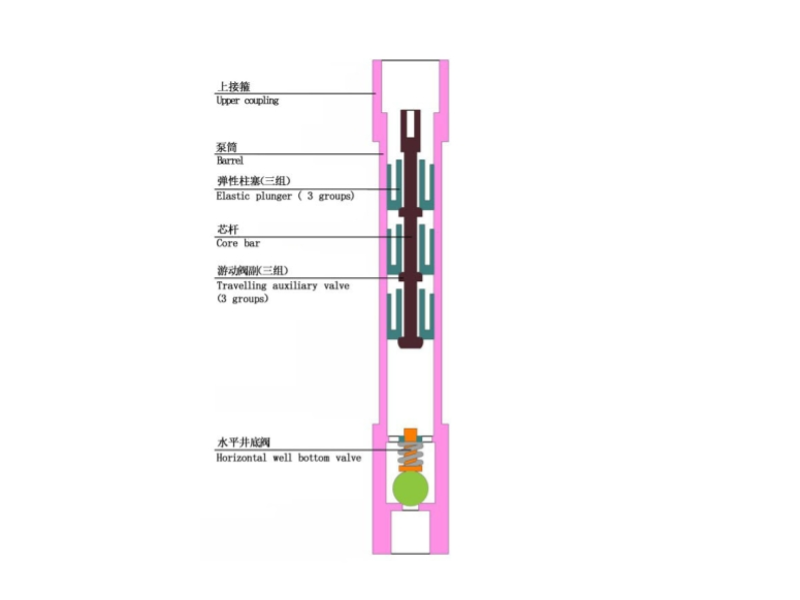

1. Our strong opening and closing sucker oil pump has brought our customers stable operation, increased daily oil production, thousands of yuan in annual electricity bill savings, and reduced pump stoppage and maintenance times through large flow channel design, low-resistance opening and closing structure and precision matching parts.

2. The key components of the strong opening and closing sucker oil pump are made of hard alloy, which is wear-resistant and corrosion-resistant. Combined with reasonable structural design, the frequency of pump body replacement is reduced, which can save labor and production stoppage costs.

3. The strong opening and closing sucker oil pump has an automatic self-aligning function and modular structure, which can be flexibly adapted to vertical wells, inclined wells, deep wells and other well types. It is easy to disassemble and assemble on site without special tools. It is more economical to purchase and faster to maintain, reducing the difficulty and cost of well team operation and maintenance.

Strong opening and closing sucker oil pumpHeavy oil recovery downhole pumpSucker rod pumpFixed barrel bottom fixed rod pump for deep wells

Email

More