09-03/2025

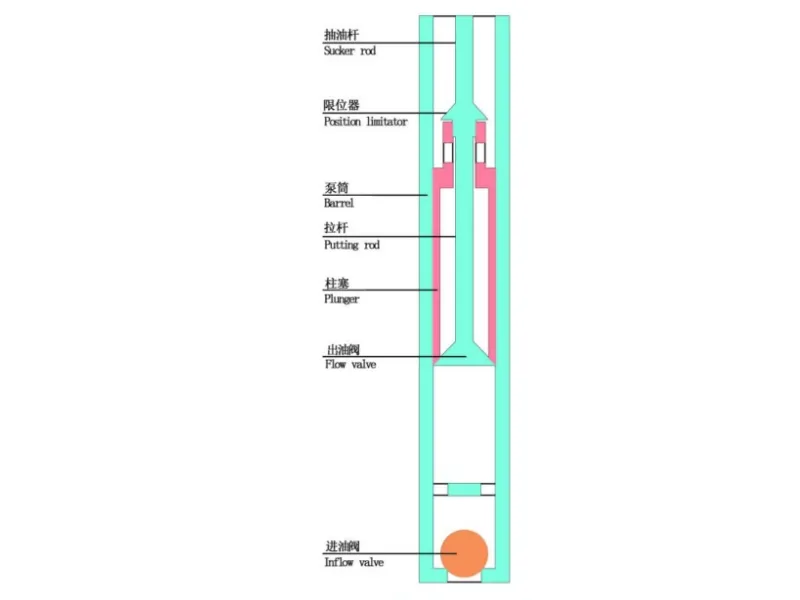

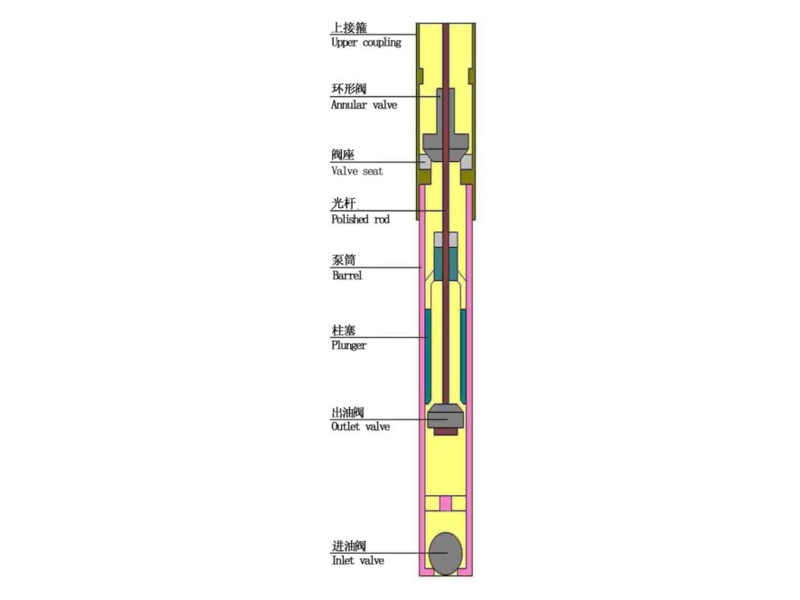

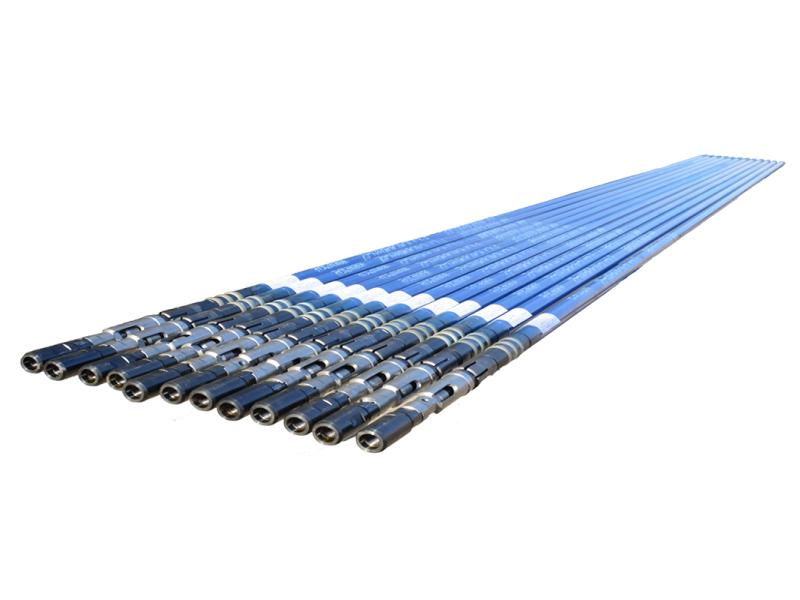

Artificial lift oil recovery method is a method of artificially replenishing energy to the bottom of an oil well and lifting oil from the reservoir to the wellhead. It is a key technical link in oil recovery engineering. After decades of development, a number of lifting technologies such as oil pumps, screw pumps, electric submersible pumps, and air lifts have been formed to meet the needs of conventional oil recovery, but at the same time there are also a series of problems such as low efficiency, high energy consumption, and short pump inspection cycles. In recent years, the field of unconventional oil and gas extraction has been very lively, and the difficulty of extracting oil and gas reservoirs has also increased. In the face of increasingly complex oil well lifting conditions and rising oil production costs, efficient and low-cost artificial lift technology has also become the research focus of major oil service companies.