In many oilfields, especially unconventional resource wells, traditional lifting equipment is prone to the following problems:

Short lifespan: Sandy or corrosive well fluids cause rapid wear of the pump body;

Frequent maintenance: Frequent well shutdowns for inspections lead to reduced production;

High labor dependency: Experienced technicians are required to maintain operation.

These pain points are driving more and more buyers in 2025 to seek solutions that reduce O&M costs while ensuring long-term stable operation.

Table of Contents:

Why choose an API tubing pump? (Highlighting the value of this solution)

API tubing pumps are compatible with different well depths and well conditions

Recommended Best Budget API tubing pumps in 2025

Factors affecting API tubing pump prices

How to choose the right API tubing pump

Supply and after-sales service

Why choose an API tubing pump?

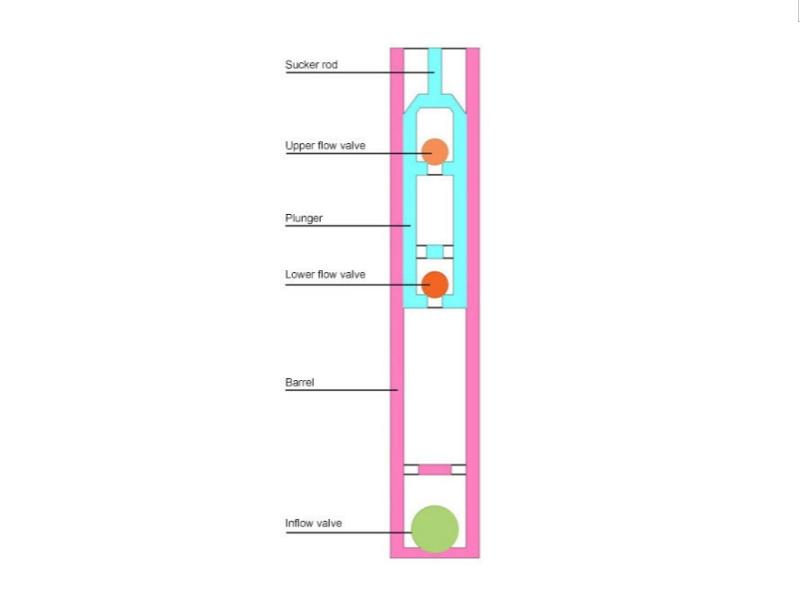

API tubing pumps (tubing pumps) are recognized for their robust construction and simplified maintenance, particularly in medium- and shallow-wells and complex well conditions. Specific advantages are as follows:

High-efficiency oil drainage: With a larger pump barrel diameter (Dongsheng's standard API tubing pumps include 32, 38, 44, 57, 70, 80, and 93 mm diameters; other diameters require custom design), API tubing pumps deliver more fluid per stroke (Dongsheng's standard API tubing pump stroke range is 1.2-6.0 mm), making them particularly suitable for high-yield or high-gas-content wells and significantly improving lift efficiency. Furthermore, the moving barrel design creates a vortex within the pump body, reducing sand stagnation and air resistance. Furthermore, the potential volumetric efficiency reaches 75%–90% compared to similar high-efficiency pumps, enabling continuous and stable extraction.

Note: The displacement Q is calculated as K·S·N (m³/d).

K = pump constant, S = stroke range (m), N = strokes per minute (s/min).

Longer life: Wear-resistant alloys or plated materials effectively resist sand abrasion and media corrosion, reducing maintenance frequency and extending equipment lifecycle.

Versatile: API tubing pumps can be flexibly customized in terms of pump body size, valve structure, and material to suit different well depths, sand content, pressure, and corrosive environments (Dongsheng Additional Service).

Reduced labor dependency: The API tubing pump's simple structural design allows for maintenance without dismantling the entire wellbore, significantly reducing the skilled worker requirements and downtime losses.

API tubing pump compatibility with various well depths and well conditions:

The advantage of API tubing pumps lies not only in their robust construction and reliable sealing performance, but also in their flexible configuration with varying pump diameters, plunger lengths, and sucker rod specifications, adapting to shallow, medium-deep, and even complex well conditions.

Shallow and low-yield wells (pump ID 32–38 mm):

Parameters: Plunger length 0.6–1.2 m, barrel length 2.1–7.5 m, pumping constant 1.14–1.64.

Application: Suitable for low-yield wells and wells with high gas content. The smaller pump diameter ensures low energy consumption while maintaining stable lift.

Advantages: Easy installation and low maintenance costs, making it ideal for marginal oil fields or early production test wells.

Medium-deep and medium-production wells (Pump ID 44–57 mm):

Parameters: Pumping constant 2.23–3.69, connects to CYG19 sucker rods, and connects to 2 3/8" TBG tubing.

Application: Suitable for medium-deep wells or conditions with high fluid viscosity, capable of providing higher discharge rates.

Advantages: While ensuring stable discharge, it extends maintenance cycles and reduces production downtime.

Deep and high-pressure wells (Pump ID 70–93 mm):

Parameters: Pumping constant 5.52–10.26, upgraded sucker rods to CYG22/CYG25 for greater load-bearing capacity, and connecting tubing lengths increased to 3"–4".

Application: Suitable for deep wells, high-displacement wells, and wells with high sand content. The larger pump diameter increases stroke volume, ensuring effective oil discharge under high-pressure conditions.

Advantages: The heavy-duty alloy pump barrel and wear-resistant plunger withstand greater impact, reducing sand sticking and pump damage.

Special well conditions (high gas content/ Corrosive fluids):

Wells with high gas content: An anti-gas lock valve design is available to maintain continuous fluid flow and avoid pump shutdowns caused by "gas lock."

Environments containing H₂S/CO₂ or brine: Stainless steel or nickel-based alloy pump materials are recommended, and corrosion-resistant coatings are added to the plunger and valve seat surfaces to significantly extend service life.

With a full range of pump diameters from 32 mm to 93 mm, various plunger lengths, and sucker rod specifications, API tubing pumps cover the full range of operating conditions, from shallow and low-yield wells to deep and high-pressure wells. Buyers simply select the model based on well depth, production rate, sand content, and well fluid properties to achieve a solution that balances efficiency and service life.

Best budget API tubing pump recommendations for 2025:

Selecting an efficient and durable API tubing pump (tubing pump) within a manageable budget is a top priority for buyers. The following points will help you quickly identify the right solution when selecting a suitable pump.

1. How to choose the right API tubing pump:

The key to selecting a suitable pump lies in the pump diameter, plunger length, and sucker rod specifications. The larger the pump diameter, the higher the displacement; the plunger and barrel lengths determine the pump's stroke volume; the sucker rod specifications influence the pump's load-bearing capacity. Choosing the right pump based on well characteristics can help achieve the optimal balance between efficiency and cost.

2. Well depth and production requirements:

Shallow/Low-Production Wells (depths < 2,500 m): A small pump diameter of 32–38 mm is recommended for low energy consumption and simplified maintenance.

Medium-Deep/Medium-Production Wells: A pump diameter of 44–57 mm offers higher displacement and is suitable for daily, stable production.

Deep/High-Production Wells (depths > 3,500 m): A large pump diameter of 70–93 mm paired with CYG22/25 heavy-duty sucker rods ensures continuous lift under high-pressure conditions.

3. Well fluid properties (sand content/high temperature/ corrosive):

For wells with high sand content: Use pump barrels and plungers that are spray-coated with carbide or hardened to effectively prevent sand sticking.

For high-temperature wells: Use high-temperature-resistant alloys to maintain the stability of valves and sealing systems.

For corrosive well fluids (containing H₂S/CO₂ or brine): Stainless steel or nickel-based alloy pump materials are recommended, along with anti-corrosion coatings to significantly extend service life.

4. Maintenance and life expectancy:

Budgetary choices do not necessarily mean sacrificing service life. Appropriate material selection and structural optimization can ensure that API tubing pumps maintain a longer operating cycle while maintaining low costs, reducing replacement frequency, lowering maintenance costs, and ensuring stable well output.

5. After-sales service and technical support:

For overseas buyers, after-sales and technical support are among the most important considerations. Choosing a supplier that provides remote installation guidance, operator training, and spare parts support will determine long-term return on investment more than simply price.

In 2025, the criteria for selecting the best budget API tubing pump will not only be price, but also well suitability, material durability, and after-sales service. Comprehensive considerations are essential. Only by selecting the appropriate model based on well depth, production rate, and fluid properties, combined with a reliable service system, can efficient, stable, and cost-effective oil well production be truly achieved.

What factors influence API tubing pump prices?

1. Materials and processing:

High-end materials (nickel-based alloys, stainless steel): Suitable for high-temperature, highly corrosive well fluid environments, offering enhanced wear and corrosion resistance, significantly extending service life, but also increasing price.

Ordinary alloy steel: Suitable for conventional, medium-shallow wells, affordably priced, but with a shorter service life in wells containing H₂S/CO₂ or high sand content.

Process Precision: High-precision machining and special surface treatments (such as carbide spraying and hardening) can reduce wear and sand sticking, extend maintenance intervals, and also increase price.

2. Specifications and models:

Well Depth Requirements: Deep wells (>3,500 m) require larger pump diameters and high-strength sucker rods, resulting in higher overall costs.

Pump Bore and Displacement: From 32 mm to 93 mm Different diameters directly affect stroke volume and oil discharge efficiency. The larger the pump diameter, the higher the price.

Customization: Non-standard designs for special well conditions (such as extended plungers or high-pressure designs) will increase the unit cost.

3. Supporting components:

Valve Systems: High-end valves utilize wear-resistant alloy or ceramic valve balls, significantly improving sealing and durability.

Plungers: Chrome-plated or carbide-sprayed plungers can extend life by 30–50%, but are more expensive than standard plungers.

Pump Barrels: Thick-walled alloy pump barrels perform better in sand-laden and high-pressure wells, but investment costs increase accordingly.

4. Brand and supplier service:

Internationally renowned brands: They are generally more expensive than domestic brands, but offer advantages in quality stability and service assurance.

Supplier Service: Suppliers that provide remote installation guidance, technical training, and spare parts support. While the initial price of their equipment may be slightly higher, this can significantly reduce subsequent downtime and maintenance costs.

Full-Life Support: High-quality suppliers offer not only products but also "solutions," which are often more valuable to overseas customers than the price of the equipment itself.

API tubing What are the key points for pump operation and maintenance?

Supplier value and service:

The value of an API tubing pump lies not only in the equipment itself, but also in the supplier's ability to provide long-term, reliable service and support. As a professional API tubing pump manufacturer, Dongsheng is committed to providing customers with a full-cycle, one-stop solution.

1. Installation and commissioning:

Dongsheng provides overseas customers with detailed installation instructions and remote video support.

2. Technical training and remote support:

Dongsheng offers customized training courses tailored to the technical level of each customer's team, covering pump operation, maintenance, and troubleshooting. Through the remote technical support platform, customers can receive real-time guidance from engineers at any time.

3. Spare parts supply guarantee:

Dongsheng maintains inventory of key spare parts, such as valves, plungers, and pump barrels, in core markets. This allows customers to quickly replace worn parts during equipment operation, reducing the risk of production interruptions.

4. Delivery lead time:

Typically, it takes 8-10 days. Weeks. For other special circumstances, please contact us and we can expedite the process upon negotiation.

5. Long-term partnership and one-stop solutions:

We not only provide individual products, but also offer selection recommendations, custom designs, and complete lifting solutions tailored to your well conditions. Long-term partners enjoy regular visits, annual maintenance plans, and technical upgrade support, helping to reduce overall operational and maintenance costs.